Efficient processing equipment for cold extraction plant marinating seasoning liquid

A technology of processing equipment and seasoning liquid, which is applied in the field of high-efficiency processing equipment for cold-extracted vegetable marinade seasoning liquid, which can solve the problems of inability to achieve precise control of brine composition ratio, marinade cannot be reused, and cannot be fully utilized. , to achieve the effect of improving follow-up utilization, improving utilization rate, and high-precision taste control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

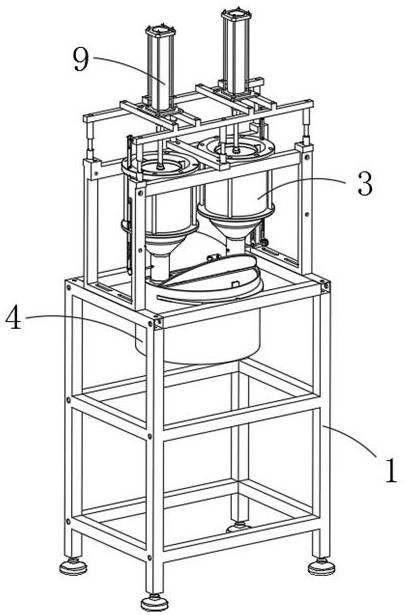

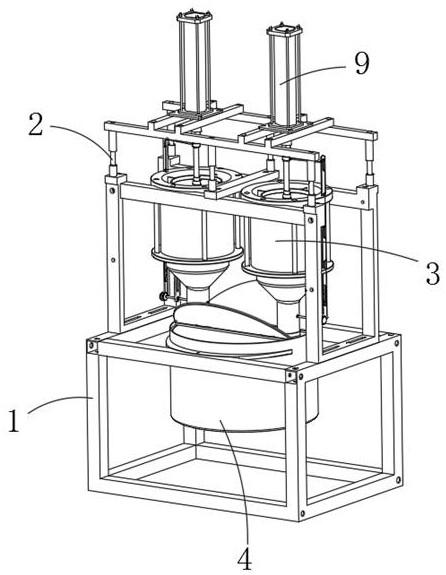

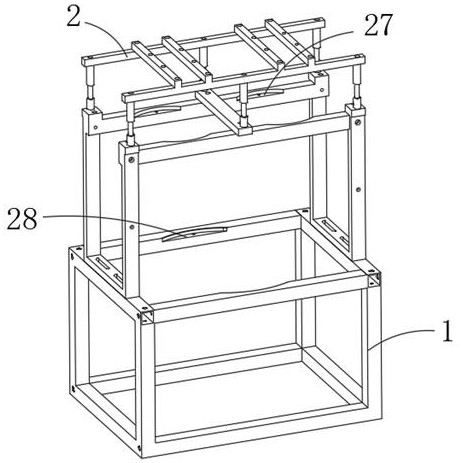

[0038] Such as Figure 1-6 As shown, a high-efficiency processing equipment for cold-extracted stewed seasoning liquid, including a mounting frame 1, a lifting table 2 is fixedly installed on the top of the mounting frame 1, and a plurality of brine barrels 3 are arranged on the mounting frame 1, and a plurality of brine The bucket 3 is respectively provided with brine storage funnels 7 for storing different types of brine, and the inner walls of multiple brine storage funnels 7 are fixedly socketed with squeeze discs 8 for squeezing different types of brine. The aperture of the filter hole on the top is suitable for the corresponding type of brine material, and the lifting platform 2 is fixedly installed with a pressing assembly that is compatible with the pressing plate 8. When the pressing assembly is in operation, it cooperates with the corresponding pressing plate 8. The brine is squeezed and purified; multiple brine barrels 3 are provided with water injection pipes and h...

Embodiment 2

[0046] Such as Figure 7 As shown, the difference between the second embodiment and the first embodiment is that the brine tank 4 can also be provided with a communication pipe 24 communicating with it, the bottom end of the communication pipe 24 is located at the bottom of the brine tank 4, and the communication pipe 24 The top height of the brine tank 4 is greater than the top height of the brine tank 4. The concentration detection mechanism 6 is used in the above-mentioned embodiment one to detect and analyze the proportioning content of various brine materials in the brine, which is suitable for batch industrial production and improves the brine preparation rate. At the same time, it is possible to accurately control the ratio of the brine material in the complex formula brine. In this embodiment, the connecting pipe 24 connected with the brine tank 4 is used to facilitate external operators to directly dip into the prepared brine through the connecting pipe 24, thereby Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com