Bottle discharging machine for tea fermentation bottles

A technology for tea fermentation and bottling, which is applied to the field of tea fermenter bottles, can solve the problems of high humidity of tea embryos, easily damaged tea embryos, low production efficiency, etc., and achieves wide adaptability of raw materials, low labor intensity, and high production efficiency. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

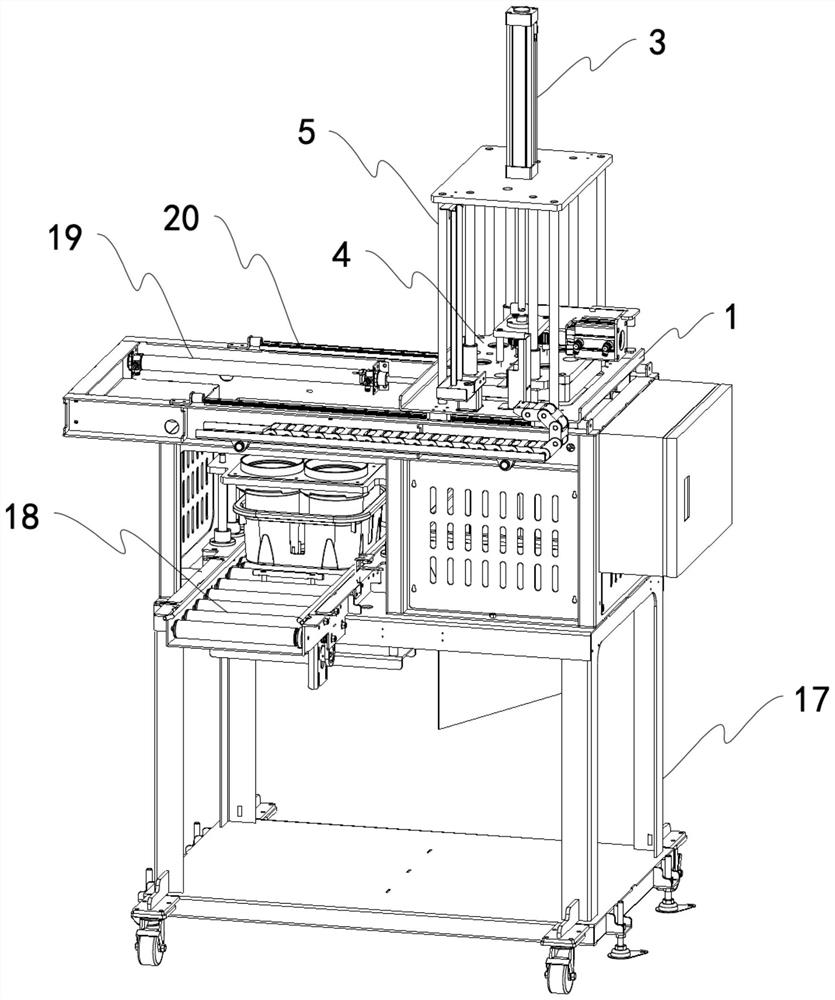

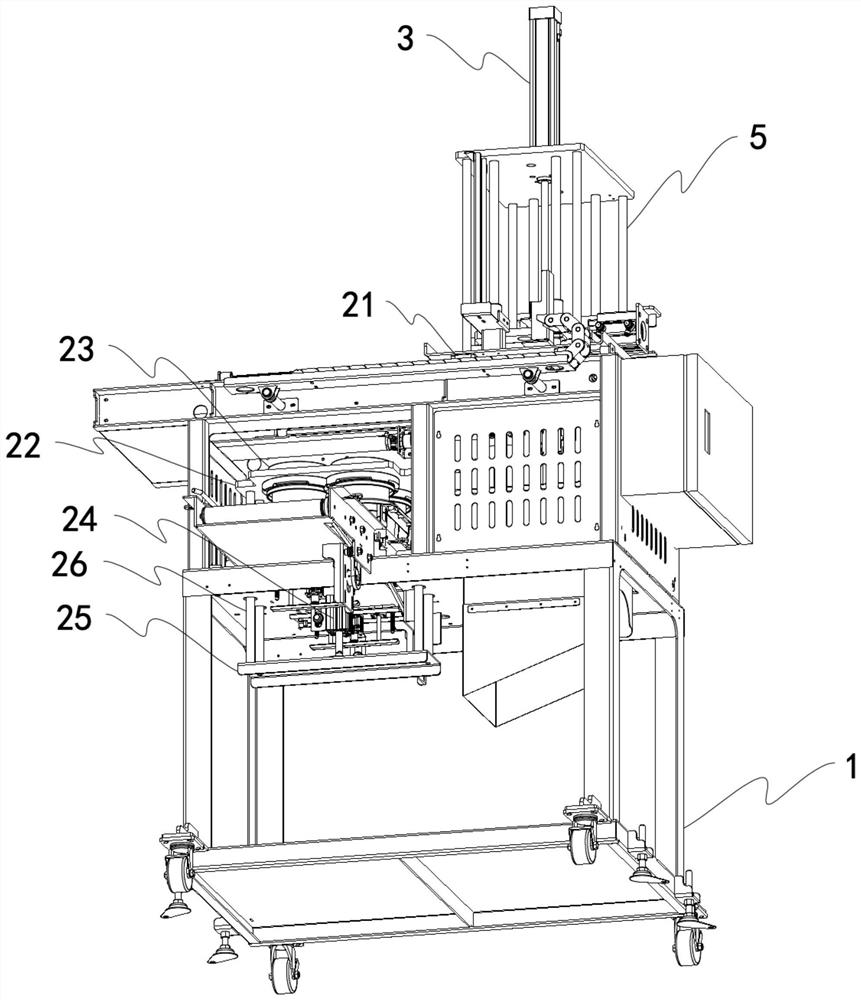

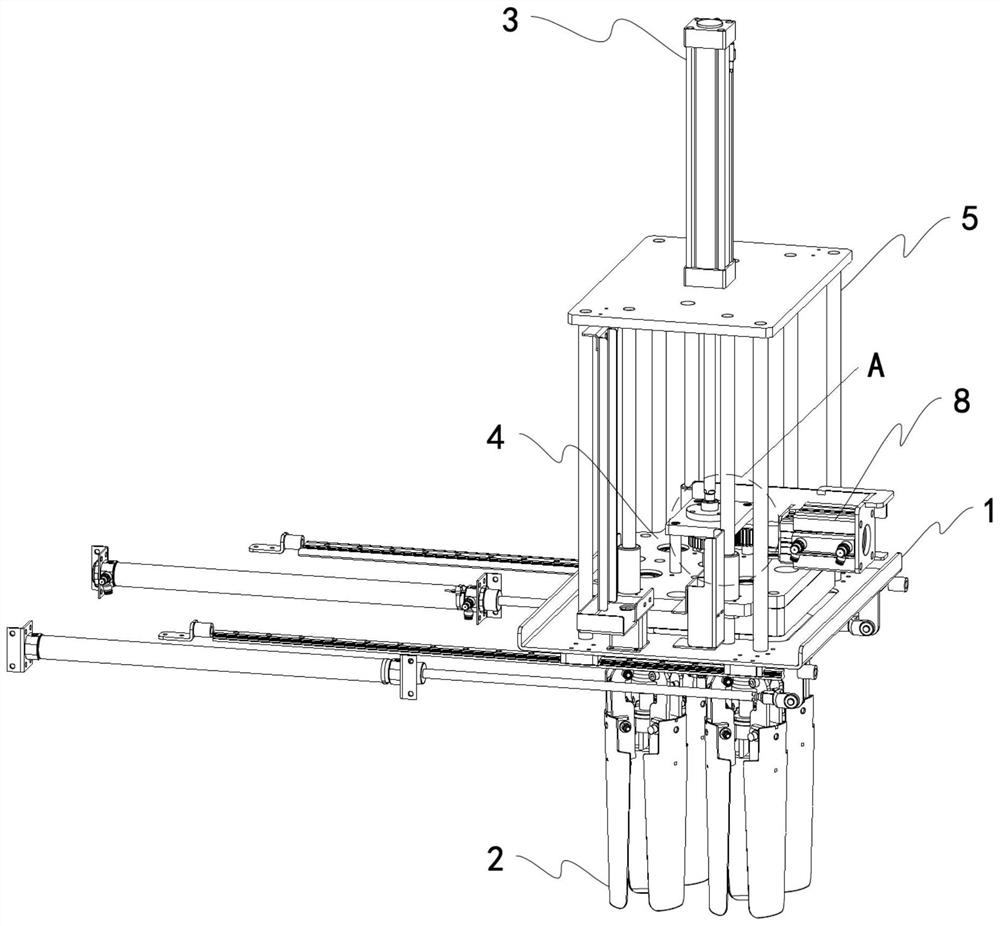

[0023] Such as Figure 1-6 As shown, a bottle discharger for tea fermentation bottles comprises a bottle discharge installation plate 1 and a bottle discharge mechanism located on the bottle discharge installation plate 1, the bottle discharge mechanism includes a bottle digging knife 2, drives the bottle digging knife 2 to close The retractable assembly, the rotary assembly that drives the bottle digging knife 2 to rotate, the upper pressure cylinder 3 and the push knife plate 4; The piston rod of the air cylinder 3 is set downwards and connected to the push knife plate 4, the rotating assembly is arranged on the push knife plate 4 and connected to the bottle digging knife 2 arranged at the bottom of the push knife plate 4, and the retractable assembly is arranged on the push knife plate 4. The knife plate 4 is connected with the bottle digging knife 2; the bottle outlet mounting plate 1 is provided with a relief hole for the push knife plate 4 to pass through.

[0024] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com