All-optical sorting method and device for micro-nano particles

A technology of micro-nano particles and sorting device, which is applied in the field of all-optical sorting of micro-nano particles, and can solve the problems of complex structure and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

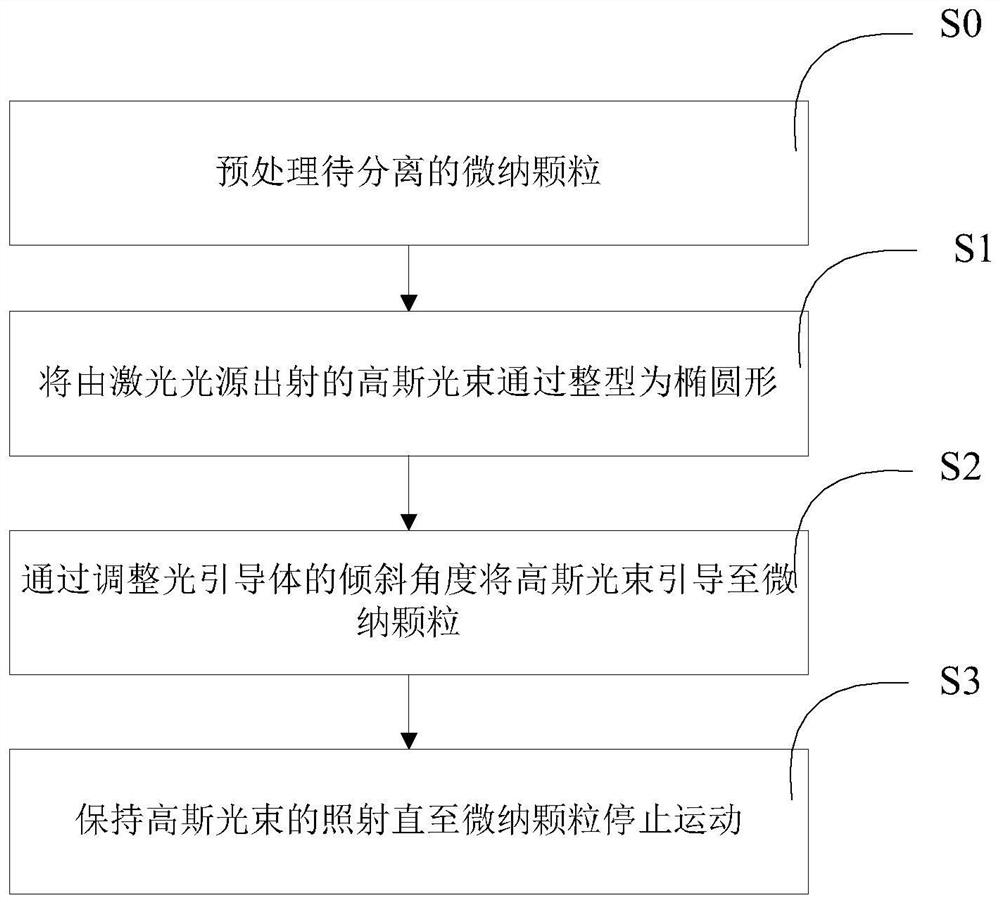

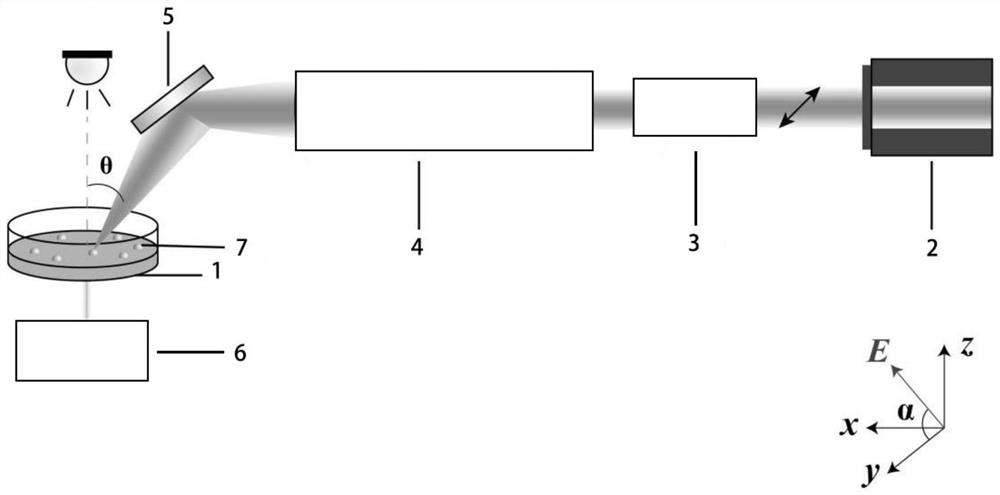

[0031] Such as figure 1 As shown, a method for all-optical separation of micro-nano particles provided in this embodiment is used to separate micro-nano particles of different particle sizes, which includes the following steps in sequence:

[0032] S0, pretreating the micro-nano particles to be separated, so that the micro-nano particles can freely move and suspend in the liquid, and partially expose the surface of the liquid;

[0033] S1. Reshape the Gaussian beam emitted by the laser emitting component into an ellipse through the shaping component;

[0034] S2. Guide the Gaussian beam to the micro-nano particles by adjusting the inclination angle of the light guide body, and make the Gaussian beam satisfy the first condition and the second condition;

[0035] S3. Maintain the irradiation of the Gaussian beam until the micro-nano particles stop moving.

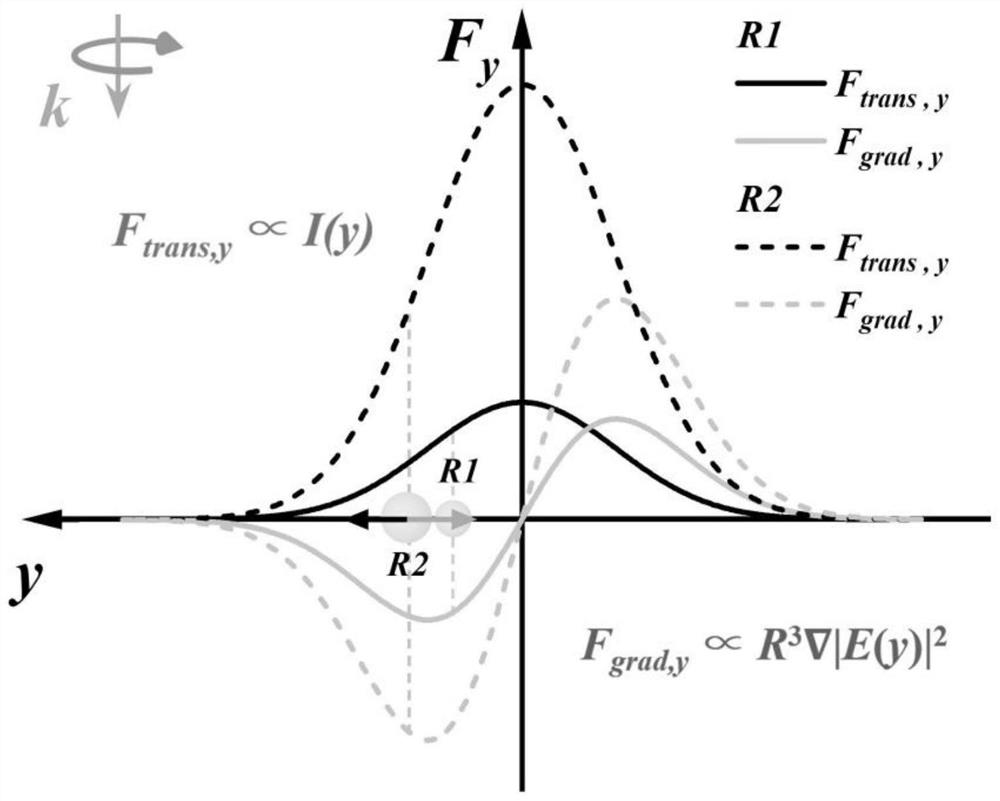

[0036] Wherein, the first condition is specifically: a Gaussian beam forms an elliptical spot with a major axis and a min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com