Mechanical part detection platform for workshop production

A technology of mechanical parts and detection platform, which is applied in the field of mechanical equipment, can solve problems such as inability to adjust, difficult detection, and high physical exertion, so as to prevent impact, improve practicability and reliability, and prevent injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

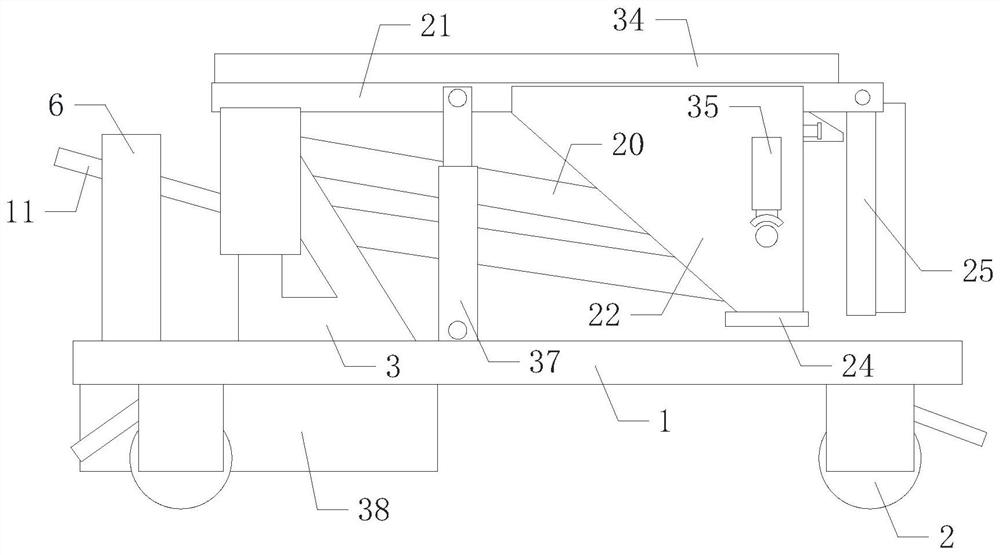

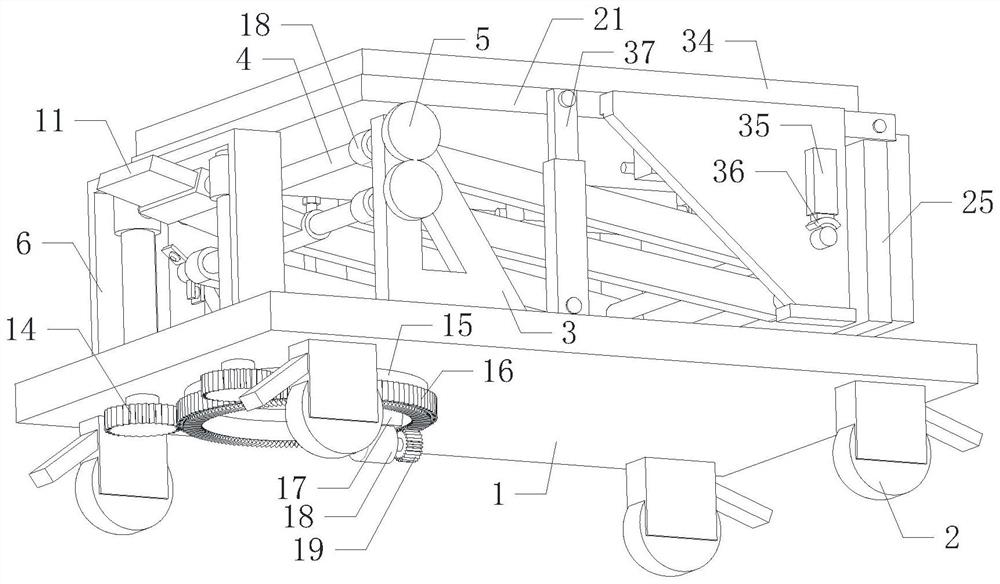

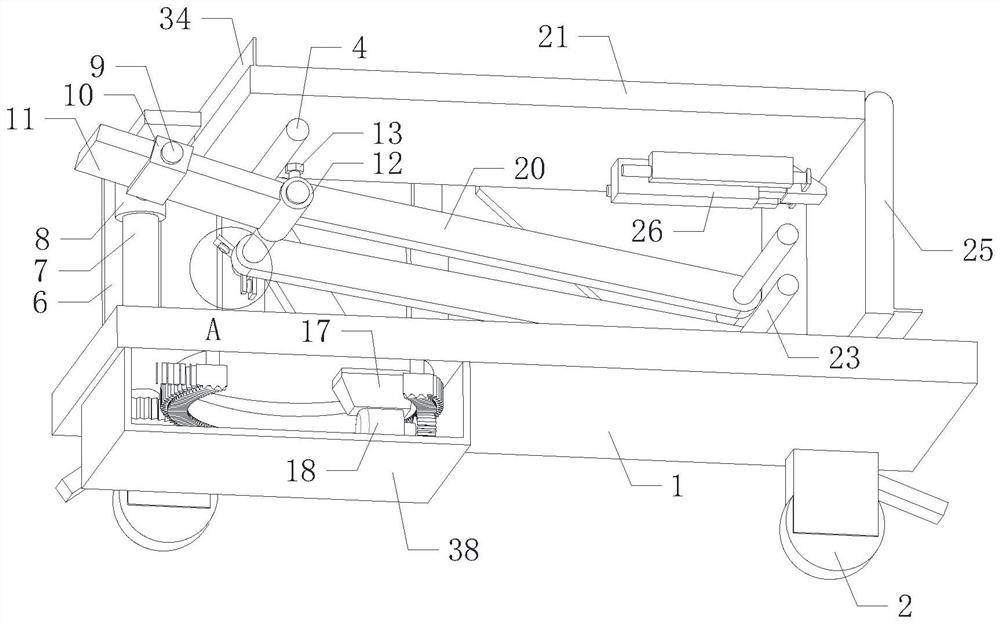

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0020] like Figure 1 to Figure 5 As shown, a kind of machine parts detection platform for workshop production of the present invention, when it is working, the mechanical parts produced in the outside workshop can be placed on the placement table 21 and the parts are detected on the placement table 21, and the motor is turned on 18. The motor 18 drives the second gear 19 to rotate. The second gear 19 meshes with the teeth on the bottom of the rotating ring 16. The second gear 19 drives the rotating ring 16 to rotate. The rotating ring 16 slides on the circular slide rail 15. At the same time, the rotating ring 16 drives Two groups of first gears 14 rotate synchronously, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com