Bearing unit

A bearing and bearing ring technology, applied in bearing components, bearings, roller bearings, etc., can solve problems such as cost increase, achieve the effect of offsetting lubricant loss, preventing pollutants from infiltrating into rolling space, and effectively assembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, identical or functionally equivalent elements are designated by the same reference numerals.

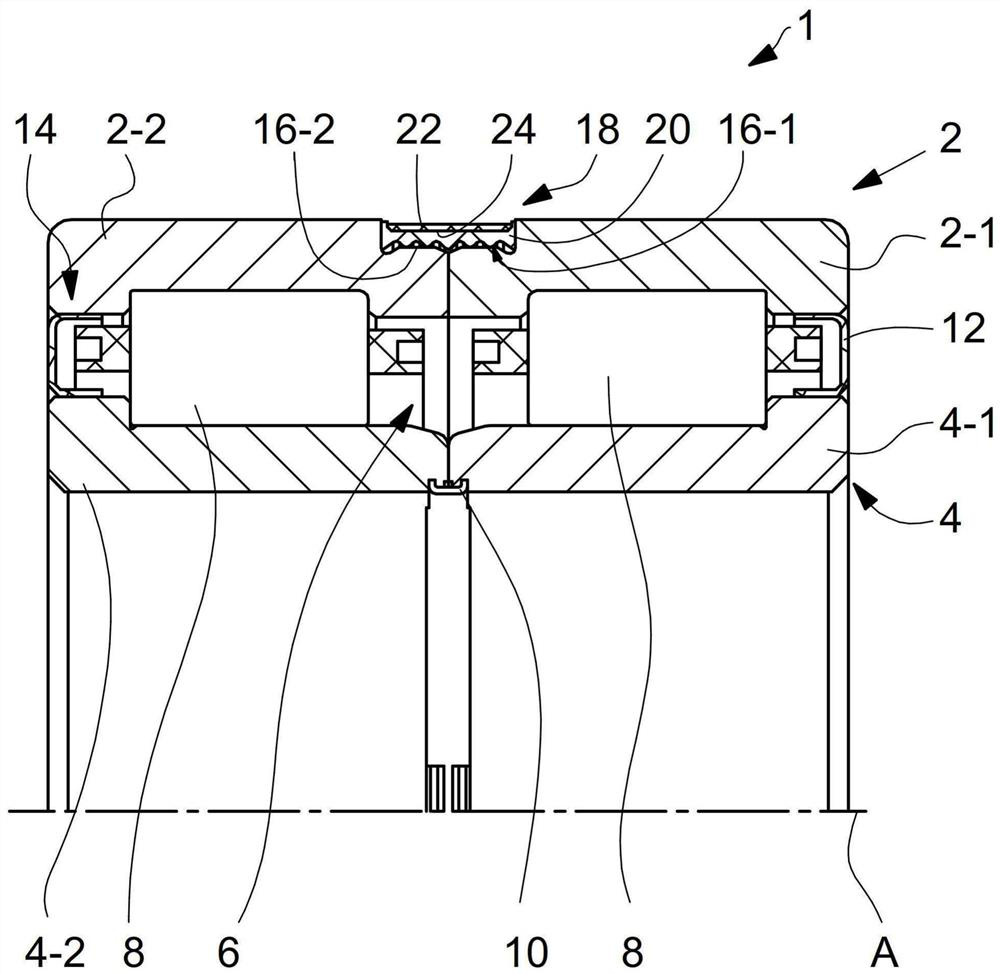

[0020] figure 1 A bearing unit 1 comprising an outer ring 2 and an inner ring 4 is shown. The outer ring 2 comprises a first bearing ring part 2-1 and a second bearing ring part 2-2. The inner ring 4 also includes a first bearing ring part 4-1 and a second bearing ring part 4-2. The outer ring 2 and the inner ring 4 are rotatable relative to each other and define between them a rolling space 6 in which a plurality of rolling elements 8 are arranged which enable the outer ring 2 and the inner ring 4 to be opposed relative to each other rotate. exist figure 1 In the bearing unit 1, the rolling elements 8 are formed as cylindrical rollers. However, other types of rolling elements may also be used, such as balls, tapered rollers, etc.

[0021] In the exemplary embodiment shown, the two bearing ring parts 4-1, 4-2 of the inner ring 4 are connected via a clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com