Compressed air energy storage system and control method thereof

A compressed air energy storage and control valve technology, which is applied in steam engine devices, liquid variable displacement machines, machines/engines, etc., can solve the problems of waste of heat energy, waste of cold energy, poor temperature followability, etc., and achieve good followability , Improve heat exchange efficiency, improve the effect of heat exchange matching degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

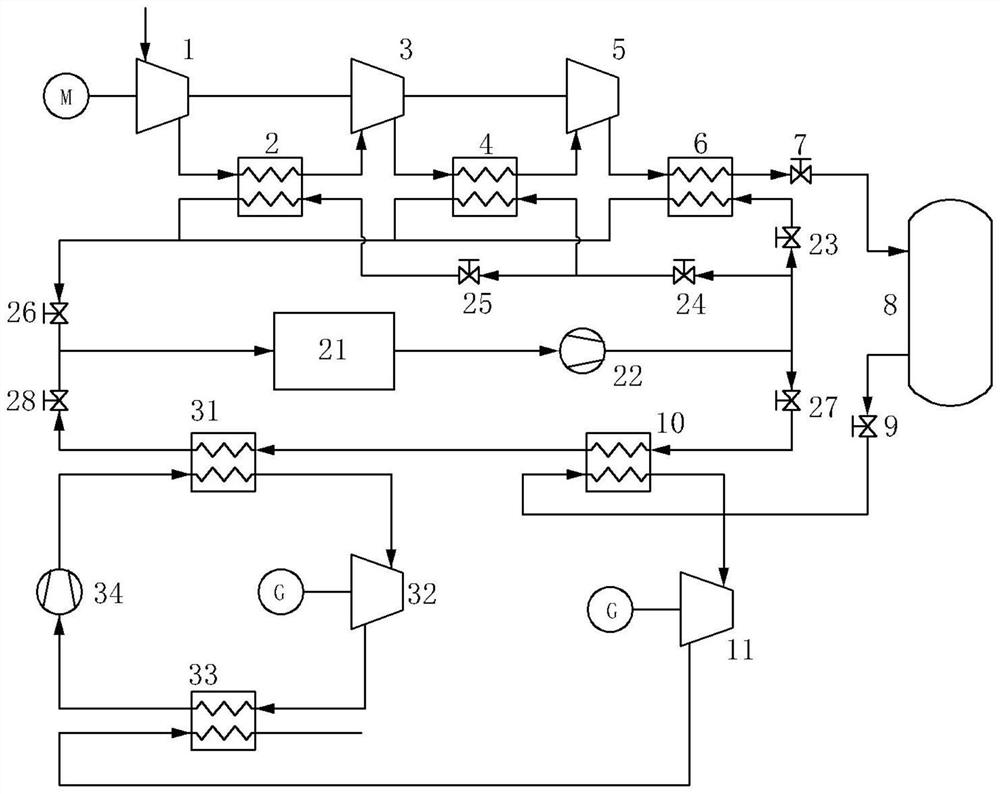

[0023] see figure 1 , a compressed air energy storage system of the present invention, the main structure includes an electric energy storage system, a thermal energy storage and release system, an electric energy release system and a triangular flash cycle system.

[0024] Among them, the electric energy storage system includes a compressor, an interstage cooler and a high-pressure gas storage tank 8, the compressor is driven by an electric motor, and low-cost electric energy drives the electric motor, and the exhaust port of the compressor is connected to the hot side inlet of the interstage cooler , the hot side outlet of the interstage cooler is connected to the high-pressure gas storage tank 8 . During the working process of the compressor, the air is compressed to a state of high temperature and high pressure, and then through the cooling effect of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com