Super-large unit curtain wall with variable-cross-section stainless steel lines and construction method

A technology of unit curtain wall and variable cross-section, which is applied in the processing of walls and building materials, construction, etc. It can solve the problems of huge keel structure and complicated design of connection nodes, and achieve simplified installation difficulty, simplified material transportation steps and costs, and simple design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

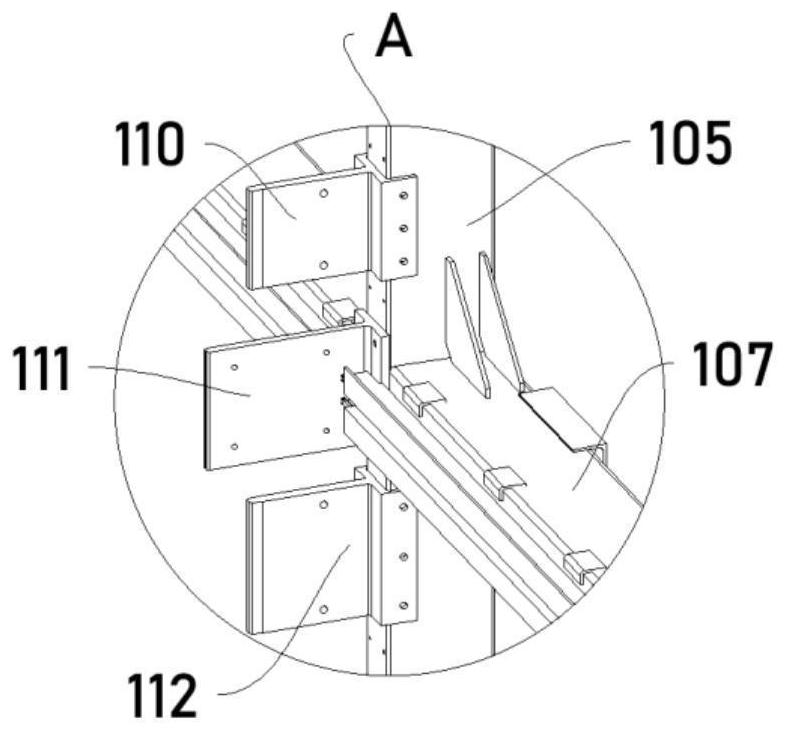

[0045] Specific as Figure 1-13 Provided is a super large unit curtain wall with variable cross-section stainless steel lines, comprising a unit substrate 1 and variable cross-section lines 2, the variable cross-section lines 2 are fixedly installed on the front of the unit base plate, the unit base plate 1 is fixedly installed on the surface of the building main body 5, and the variable cross-section lines 2. It is a cross-shaped structure. The cross-shaped variable-section lines 2 are divided into two styles: crests and troughs. Multiple groups of crests and troughs-shaped cross-shaped variable-section lines 2 are divided into horizontal and vertical waves by staggered splicing of multiple sets of unit substrates 1. Form setting;

[0046] The unit substrate 1 includes a glass frame 102, and the glass frame 102 is fixedly connected with a cross-shaped steel skeleton. The cross-shaped steel skeleton is composed of steel columns 105 and steel beams 107 welded on the left and ri...

Embodiment 2

[0057] Such as Figure 14 As shown, a construction method of a super large unit curtain wall with variable cross-section stainless steel lines includes the following steps:

[0058] S1. Standard module production, the overall structure is separated, including variable section lines 2 and unit substrate 1, variable section lines 2 are composed of gradient vertical lines 201 and gradient horizontal lines 202, gradient vertical lines 201 are divided according to the size of the main keel 20101 They are: large keel vertical lines 201a, medium keel vertical lines 201b and small keel vertical lines 201c, and gradient horizontal lines 202 are divided into large keel horizontal lines 202a according to the size and model of the front keel 20201 and rear keel 20202 and the angle of the acute angle. , small keel horizontal line 202b, large sun angle horizontal line 202c and small sun angle horizontal line 202d, each part is designed and manufactured by the factory workshop according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com