Artificial solidified stone prepared from steel slag and spoil and application method of artificial solidified stone

An artificial and fossil technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as failure to block dyke breaches, achieve high comprehensive utilization of resources, facilitate transportation and throwing, and be widely used Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

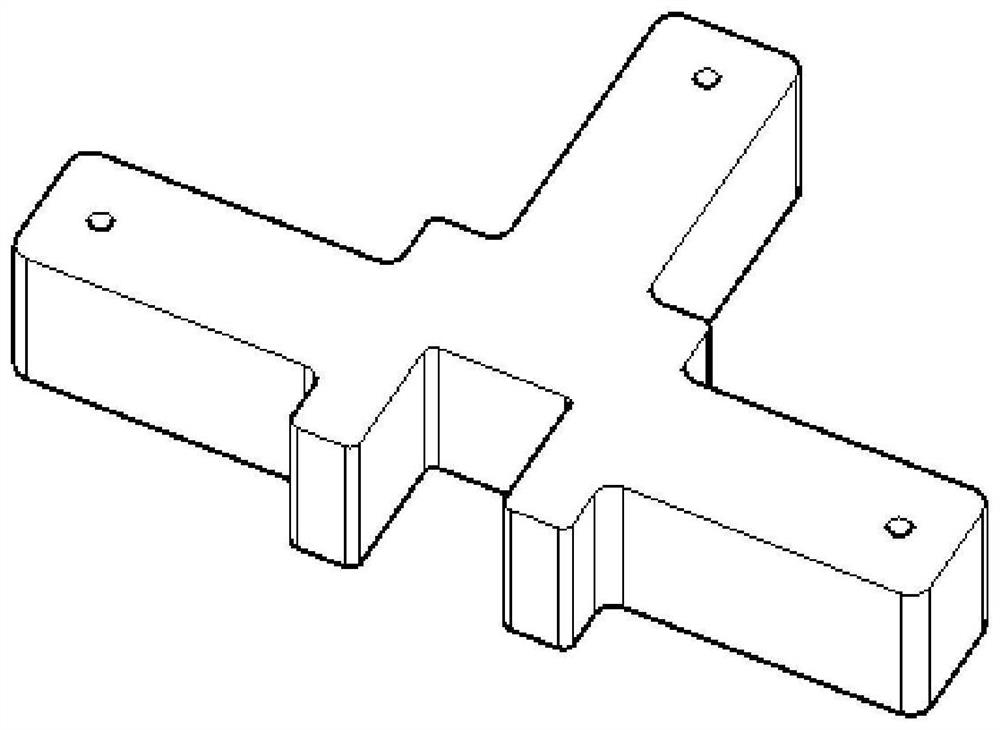

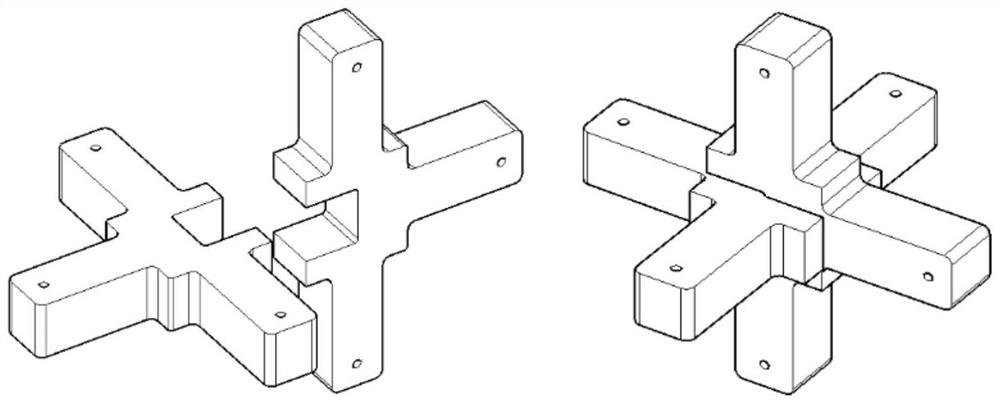

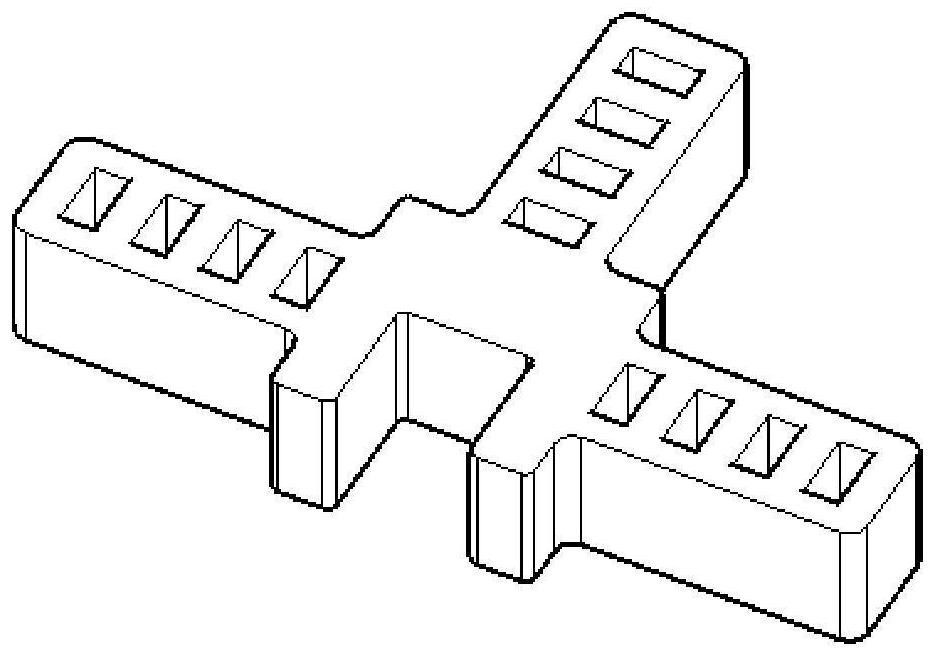

[0041] see Figure 1-3 , the artificial solidified stone of the present invention comprises a central body and a side body, the central body and the side bodies are cubic structures, one side of the central body is provided with a slot, and the other three sides of the central body and the side where the slot is located on the same horizontal plane The midpoints are respectively connected to the side bodies, the length and width of the center body are consistent and the height of the center body is half of the length of the center body; the length and width of the card slot are half of the length of the center body, and the length of the side body is Half of the length of the center body, and the width of the side body is consistent with the width of the center body; the height of the center body, side body and the slot are all the same; the artificial solidified stone of this structure is easier to calculate than the traditional irregular stone The volume and drift distance c...

Embodiment 2

[0045] A kind of artificial solidified stone that utilizes steel slag and spoil to prepare in embodiment 1 is prepared by the raw material that comprises following parts by weight: 10 parts of cement, 20 parts of spoil, 70 parts of steel slag, curing agent (calcium aluminate, aluminate The mass part ratio of sodium and sodium sulfate is 70:15:15) 0.8 parts, and the water reducer polynaphthalene sulfonate NS 1.2 parts; its preparation method includes the following steps: S1, pretreatment of spoil and steel slag: The raw materials of the spoil body are sunned, artificially removed soil impurities, air-dried and aged, and mechanically crushed with a hammer crusher to make the particle size below 5mm; place the steel slag for aging to fully expand and pulverize , and then carry out mechanical crushing and screening to steel slag, make its granularity reach below 5mm; S2, weigh material according to above-mentioned weight part;

[0046] S3. Dry mix the pulverized spoil, pulverized ...

Embodiment 3-5

[0048] The difference between Examples 3-5 and Example 2 is that the proportion of steel slag and spoil used in the batching is different, that is, the replacement rate of steel slag is different. The specific proportion is shown in Table 1, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com