Material conveying device capable of circularly feeding and discharging material layers

A technology for transporting materials and material layers, which is applied in the field of material conveying devices for circulating upper and lower material layers, which can solve problems such as high risk factor, high labor intensity, and employee injury, and achieve the effect of high degree of automation and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

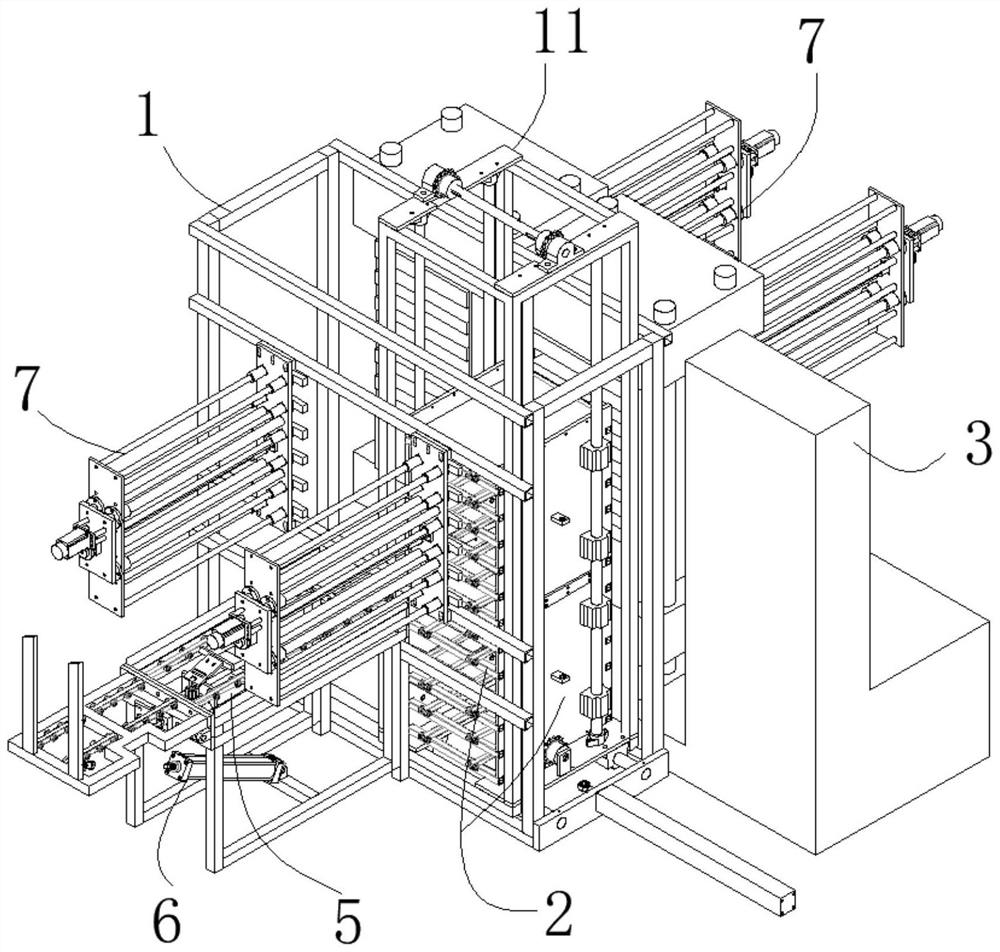

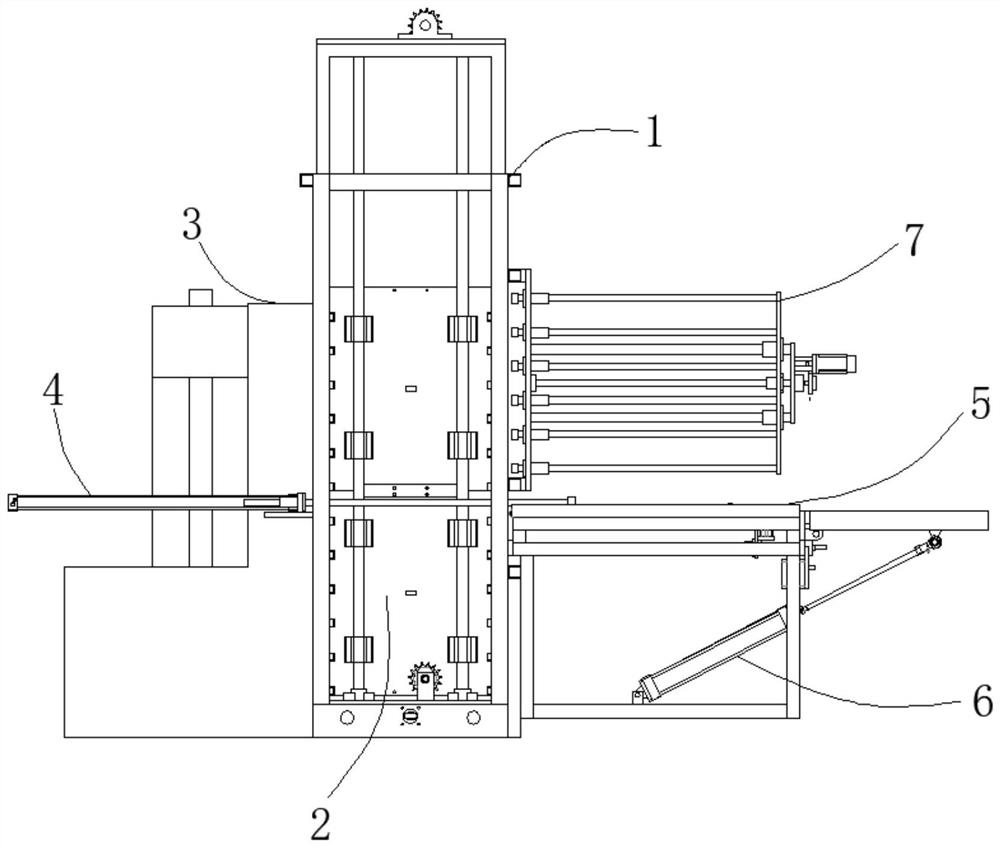

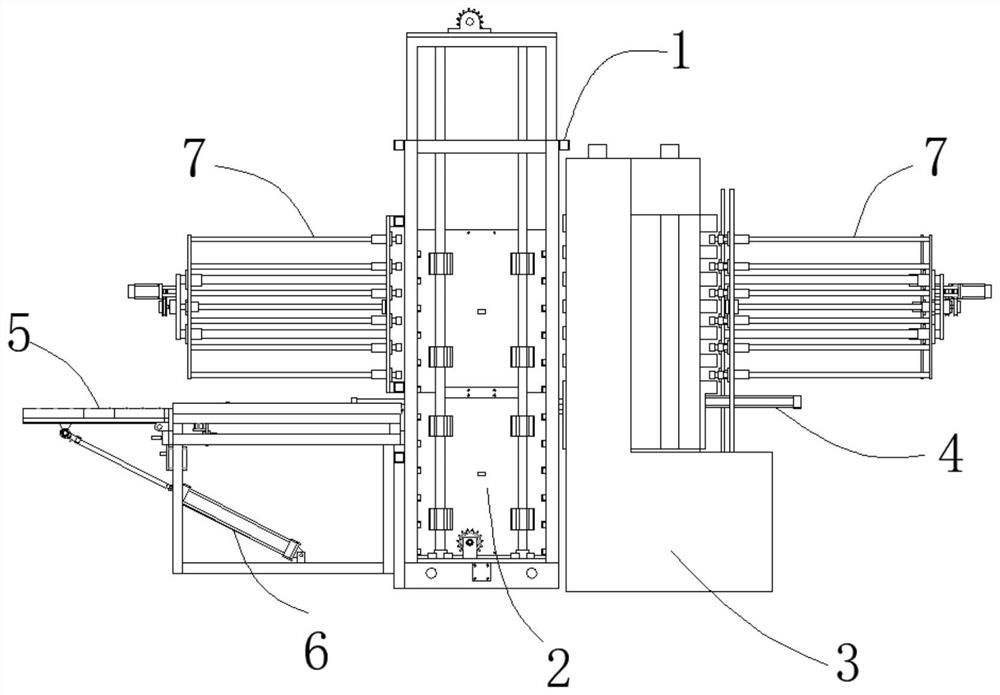

[0041] The invention proposes a conveying device for circulating upper and lower material layers. refer to Figure 1 to Figure 5 As shown, in Embodiment 1 of the present invention, the conveying device for circulating upper and lower layers includes a frame 1, a feeding platform 5 and a discharging platform 7, and one side of the frame 1 is connected to the feeding platform 7. The material table 5 is connected, and the other side of the frame 1 is connected with the discharge table 7, and a laminator 3 for processing material trays is arranged between the frame 1 and the discharge table 7; The pallet is first transported from the feeding table 5 through the frame 1 and enters the laminating machine 3. The laminating machine 3 is equipped with a hot press and a cold pressing machine, and the staff transports the pressed material pallet to the discharging table 7; The frame 1 is provided with a moving frame 11, one side of the moving frame 11 communicates with the feed table 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com