Pretreatment deslagging equipment for dairy product packaging and deslagging method thereof

A packaging and pretreatment technology, which is applied in the field of pretreatment and slag removal equipment for dairy product packaging, can solve the problems of inconvenient placement of cheese, easy concave packaging boxes, and cheese slag affecting the packaging effect, etc., so as to avoid damage, Easy to put in and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

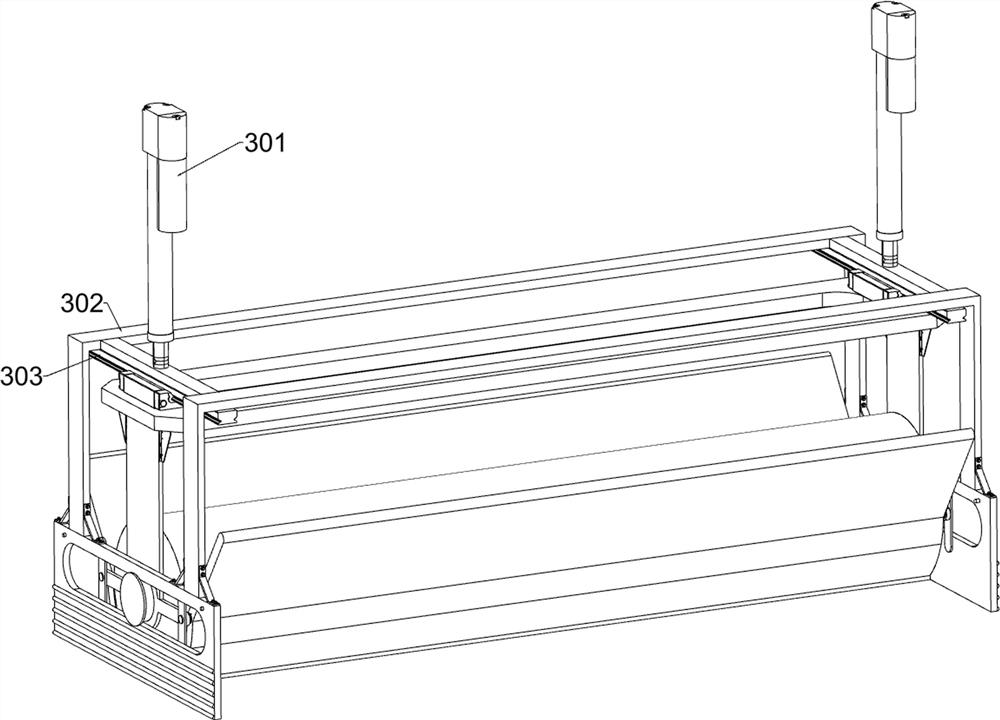

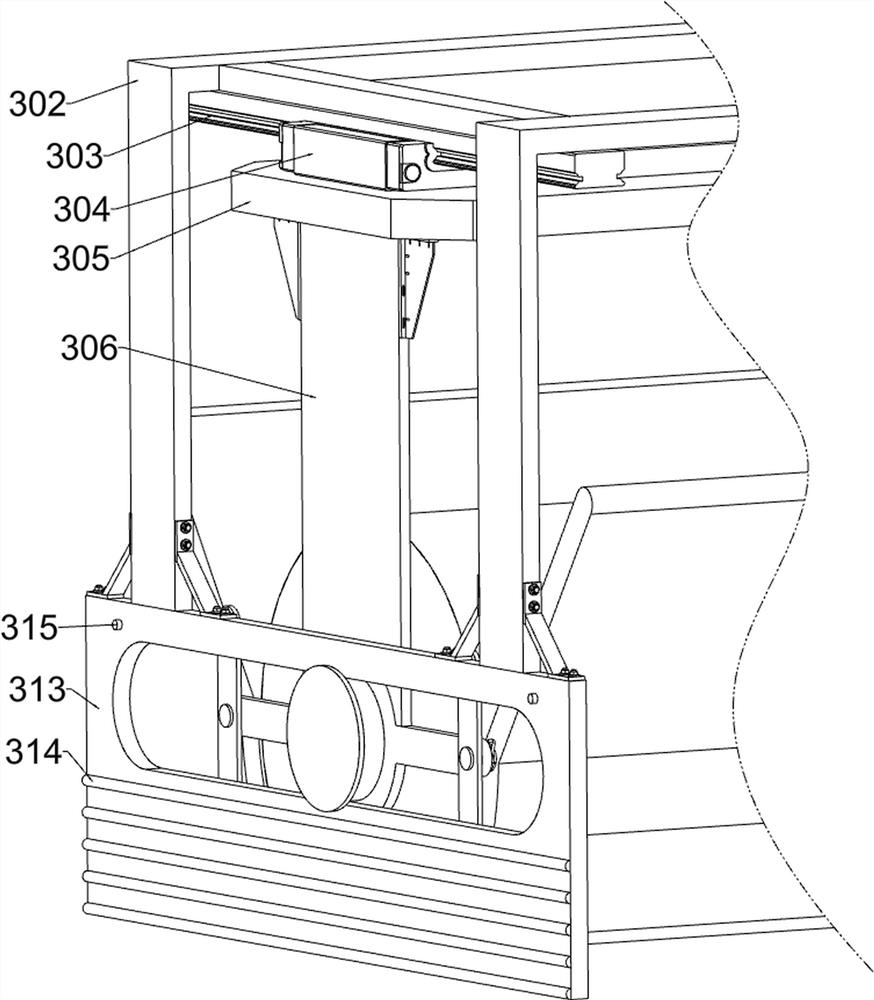

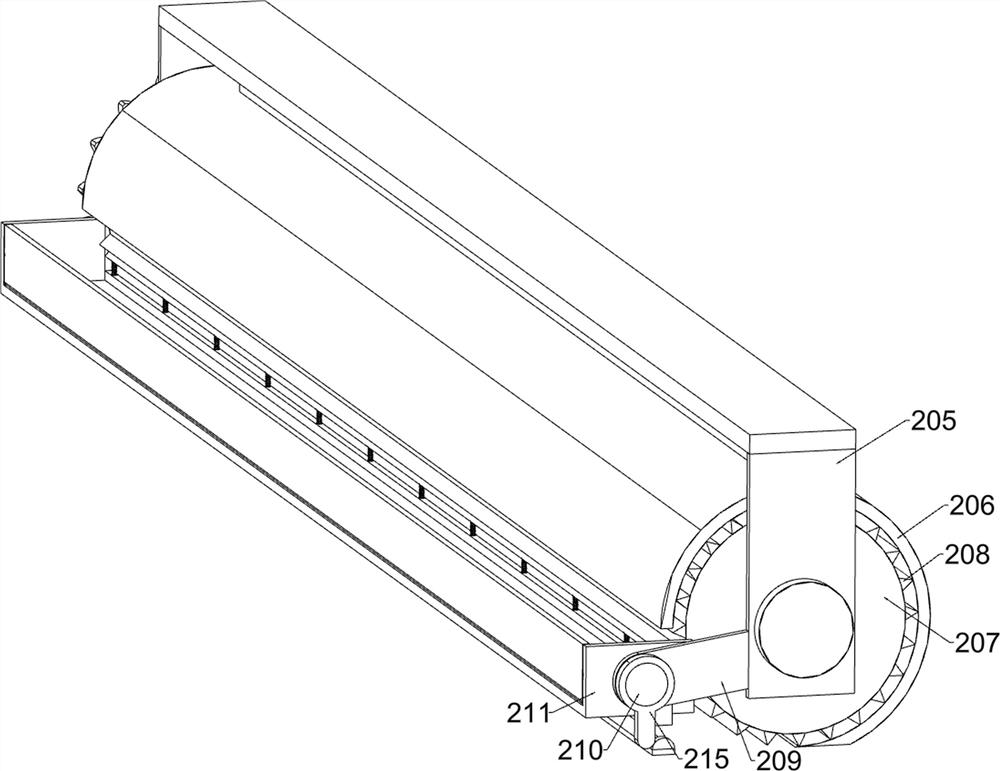

[0038] A kind of pretreatment slag removal equipment for dairy product packaging, such as Figure 1-12 As shown, it includes a support frame 1, a slag collection box 2, a placement table 3, a slag collection system and a pressing system; the slag collection box 2 is arranged on the left side of the support frame 1; Placement platform 3; the upper left part of the support frame 1 is connected to the debris collection system; the debris collection box 2 is connected to the debris collection system; the placement platform 3 is connected to the debris collection system; the upper right side of the support frame 1 is connected to There is a pressing system.

[0039] Working principle: When using the pretreatment deslagging equipment for dairy product packaging, the worker first places the cheese to be packaged on the placement table 3, controls the slag collection system to clean the surface of the cheese, and removes the protruding shards on the cheese surface. All residues are r...

Embodiment 2

[0052]On the basis of embodiment 1, a kind of method for pretreatment and deslagging of dairy product packaging comprises the following steps:

[0053] Step 1: Placement, first the worker places the cheese to be packaged on the placement table 3;

[0054] Step 2: Remove slag, control the slag collection system to clean the surface of the cheese, and remove all the slag raised on the cheese surface;

[0055] Step 3: Turn over the cheese by manually turning over the cheese, and then control the crumb collection system to clean the surface of the cheese with crumbs;

[0056] Step 4: collecting, collecting the removed slag into the slag collection box 2;

[0057] Step 5: The packaging box is leveled, and the pressing system is operated, and the cheese packaging box is pressed through the pressing system to make the inner wall of the cheese packaging box flat, so that the cheese can be put in quickly;

[0058] Step 6: Putting in, the worker places the cheese after deslagging in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com