Front double-hydraulic-cylinder wind power blade automatic mold closing device

A mold clamping device and wind blade technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of large space occupation, large space occupation, and increased factory cost, and achieve uniform load distribution, simple assembly, and The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

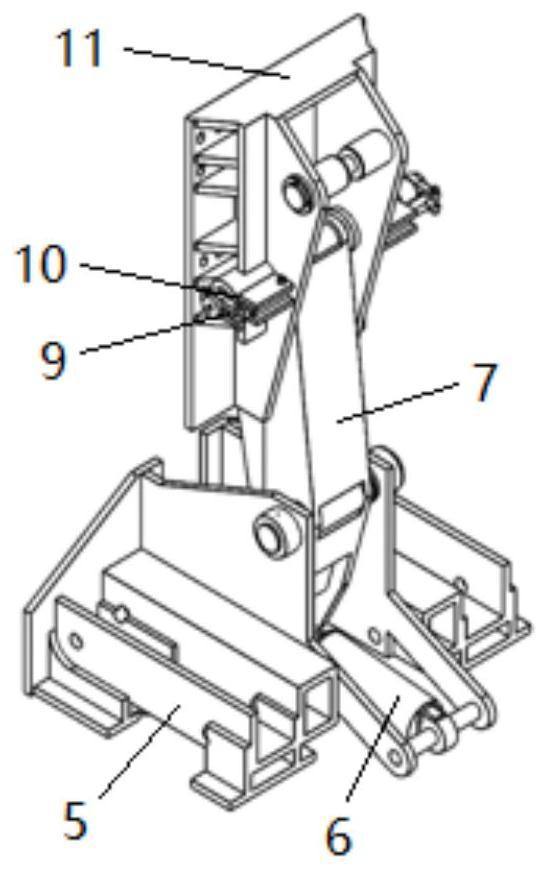

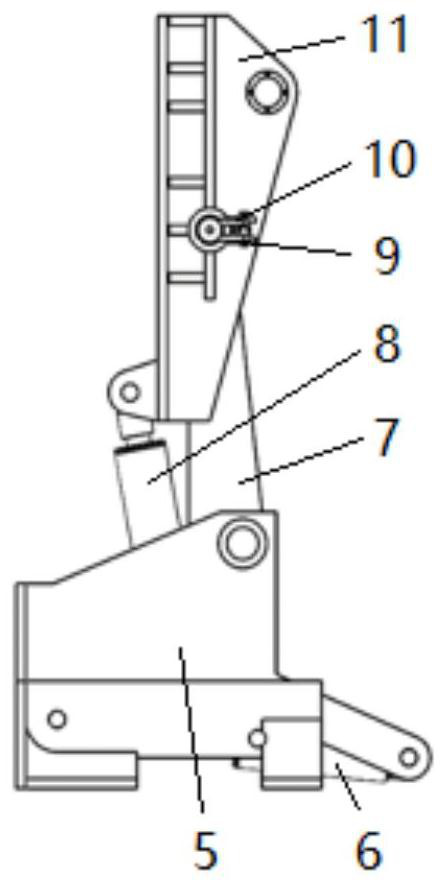

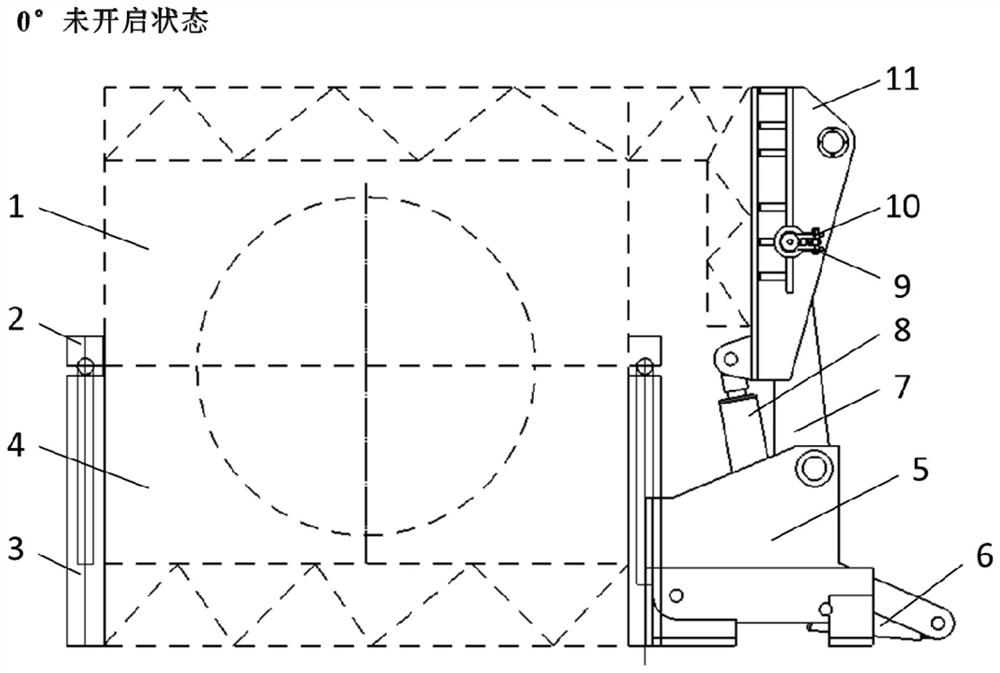

[0046] An automatic mold clamping device for wind blades with front double hydraulic cylinders, including an upper mold 1 and a lower mold 4 for making wind turbine blades, such as Figure 1-6 As shown, it also includes an overturning mechanism fixed on the base 5; the upper mold 1 and the lower mold 4 are arranged on one side of the base 5; the overturning mechanism includes a main hydraulic cylinder 6, a main rocker arm 7, an auxiliary hydraulic cylinder 8 and an auxiliary rocker arm 11 ; The main hydraulic cylinder 6 is fixed on the base 5, and the output end is connected to the main rocker arm 7; the main rocker arm 7 is connected to the base 5 in rotation; 11 transmission connection; the auxiliary rocker arm 11 is rotationally connected with the main rocker arm 7; the upper mold 1 is fixed on the auxiliary rocker arm 11, and the lower mold 4 is fixed on the base 5;

[0047] In the initial state, the upper mold 1 and the lower mold 4 are in the mold closing state;

[0048...

Embodiment 2

[0062] An automatic mold clamping device for wind blades with front double hydraulic cylinders, including an upper mold 1 and a lower mold 4 for making wind turbine blades, such as Figure 7-12 As shown, it also includes an overturning mechanism fixed on the base 5; the upper mold 1 and the lower mold 4 are arranged on one side of the base 5; the overturning mechanism includes a pair of main hydraulic cylinders 6, main rocker arms 7, auxiliary hydraulic cylinders 8 and auxiliary rockers arm 11; a connection plate is fixed on the base 5; the main hydraulic cylinder 6 is symmetrically fixed on the bottom plate on both sides of the connection plate, and the output end is connected to the main rocker arm 7; the main rocker arm 7 is connected to the connection plate in rotation; the auxiliary hydraulic cylinder The cylinder 8 is rotatably connected to the main rocker arm 7, and the output end is connected to the auxiliary rocker arm 11; the auxiliary rocker arm 11 is rotatably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com