Equipment and method for manufacturing hollow bricks by recycling agricultural straws

A hollow brick and equipment technology, which is used in agriculture, clay preparation equipment, auxiliary forming equipment, etc., can solve the problems of inability to sieve and remove, many hard particles in hollow bricks, affecting the forming efficiency of hollow bricks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

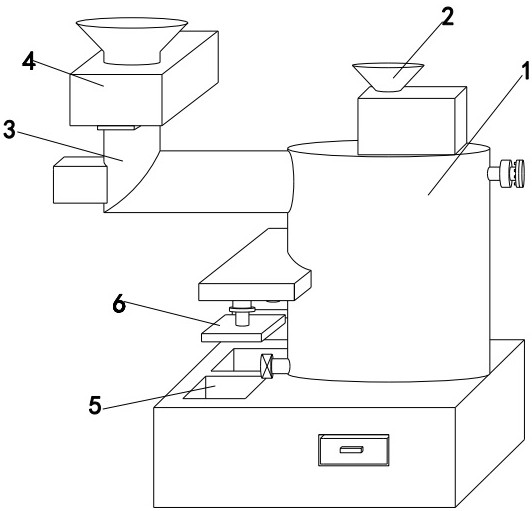

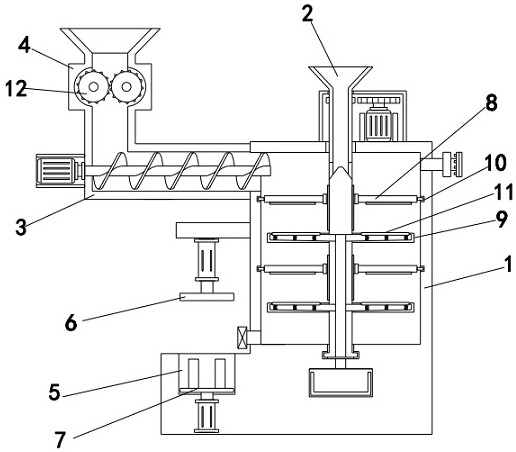

[0037] see Figures 1 to 11 , a schematic diagram of planar structure and schematic diagram of three-dimensional structure of an equipment and method for making hollow bricks by reusing agricultural straw.

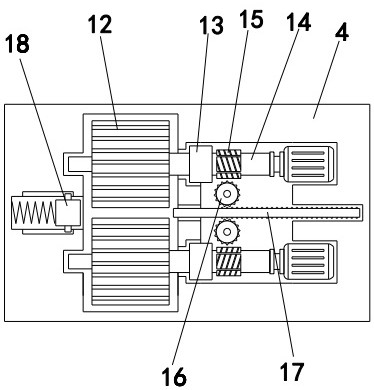

[0038] A device for making hollow bricks by reusing agricultural straw, comprising a raw material mixing main body 1, a feeding pipe 3 is installed on the left side of the raw material mixing main body 1, an extrusion crushing part 4 is arranged inside the feeding pipe 3, and an extrusion crushing part 4 is installed inside There is a crushing wheel 12 and a drive shaft 14 that drives the crushing wheel 12 to rotate. One side of the crushing wheel 12 is connected with an outer jacket 13, and one end of the drive shaft 14 is equipped with a drive block 19, and the outside of the drive shaft 14 is also provided with a threaded plate 15. A traversing rod 20 is installed inside the shaft 14, a ejector rod 17 is arranged between the two drive shafts 14 of the crushing part 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com