Positioning mechanism for die casting of cinerary casket storage rack

A positioning mechanism and storage rack technology, applied in positioning devices, storage devices, metal processing equipment, etc., can solve the problem that it is difficult to ensure that the position of the urn storage rack does not shift, and achieve the effect of reducing cumbersomeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

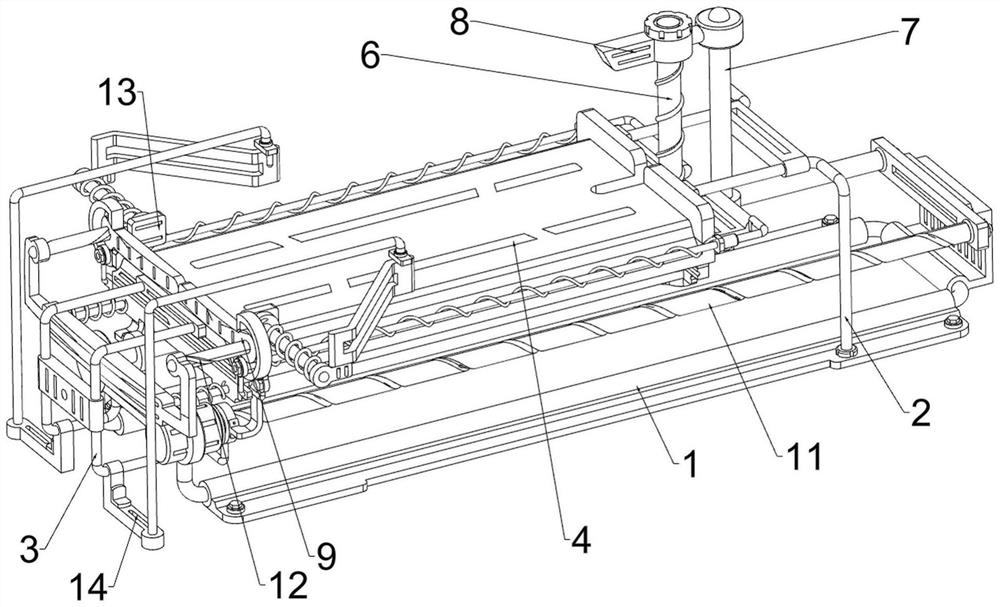

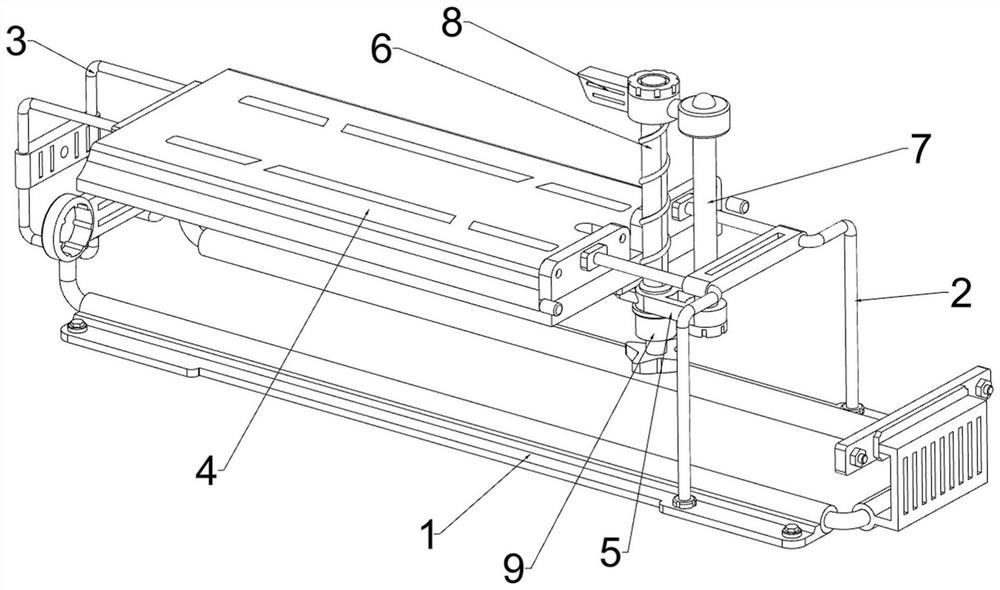

[0038] A positioning mechanism for die-casting of an urn storage rack, now for reference Figure 1-Figure 4 , including a bottom frame 1, a first mounting frame 2, a second mounting frame 3, a workbench 4, a mounting block 5, a screw rod 6, a guide rod 7, a lifting block 8, a rotating handle 9, a pushing mechanism 10 and a jacking mechanism 13 The right side of the top of the bottom frame 1 is installed with a first mounting frame 2 through bolts, and the bottom of the bottom frame 1 is equipped with an anti-slip pad, so that the bottom frame 1 is placed more stably. The left side of the bottom frame 1 is welded with a second mounting frame 3. A workbench 4 is welded between the first installation frame 2 and the second installation frame 3, the right side of the bottom of the workbench 4 is installed with a mounting block 5 through bolts, the left side of the mounting block 5 is rotatably connected with a rotating handle 9, and the top of the rotating handle 9 is riveted Ther...

Embodiment 2

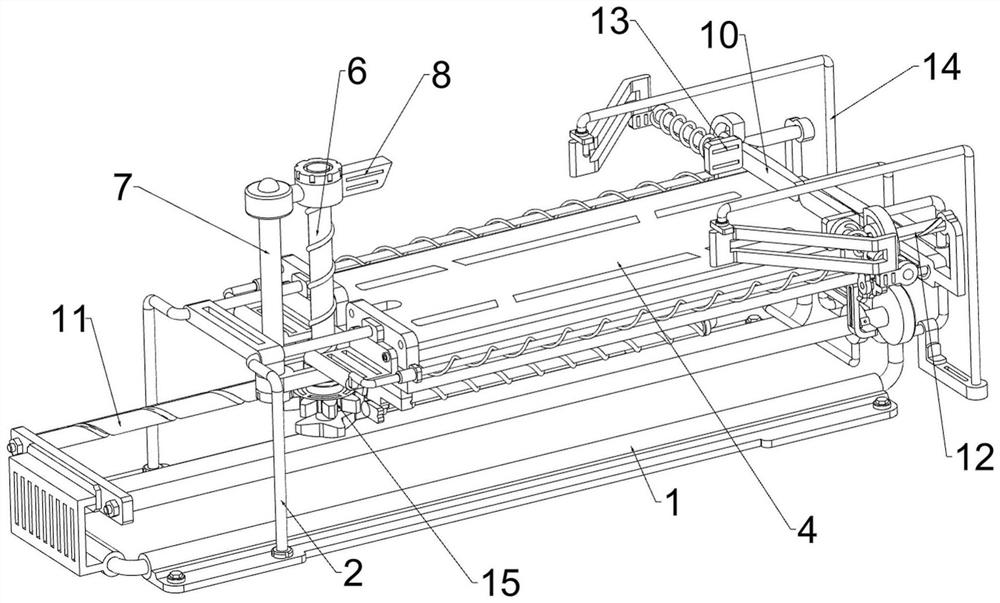

[0041] On the basis of embodiment 1, now refer to figure 2 , Figure 5 and Figure 6 As shown, the pushing mechanism 10 includes a support block 101, a connecting frame 102, a sliding block 103, a turret 104 and a return spring 105. The front and rear sides of the right side of the workbench 4 are welded with a support block 101, and the two support blocks 101 are connected to each other. The far side is connected with a connecting frame 102 by bolts, the left side of the two connecting frames 102 is slidably connected with a sliding block 103, and the two sliding blocks 103 are slidably connected with a turret 104, and the two turrets 104 are all slidably connected. Located on the top of the workbench 4, a return spring 105 is connected between the right side of the two sliding blocks 103 and the left side of the connecting frame 102 on the same side.

[0042] now refer to figure 1 , figure 2 , Figure 10 , Figure 11 and Figure 12 The jacking mechanism 13 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com