Rear-mounted ditcher soil splitter

A ditching machine, post-mounted technology, applied in the direction of excavation/covering ditches, land preparation machinery, agricultural machinery and tools, etc., can solve the problems that affect the safety of drivers, complex structure, easy to loose, etc., to achieve simple and fast process , good strength, and the effect of protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail in conjunction with embodiment now.

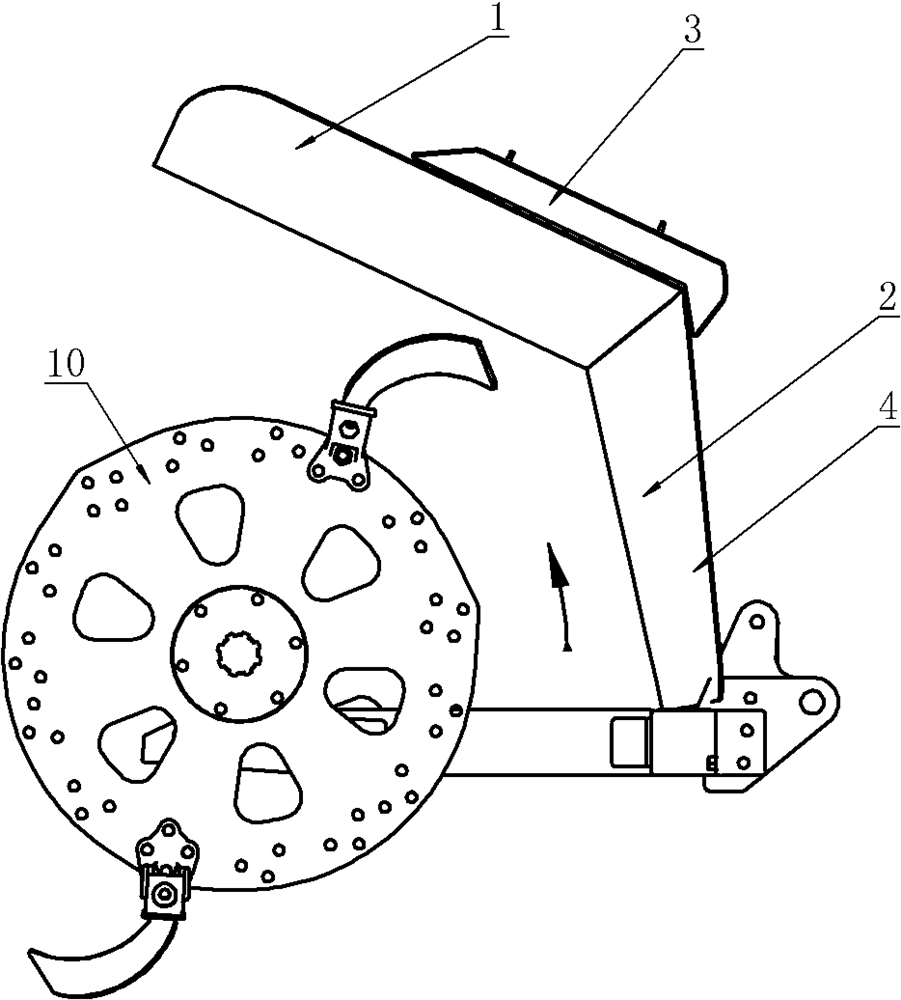

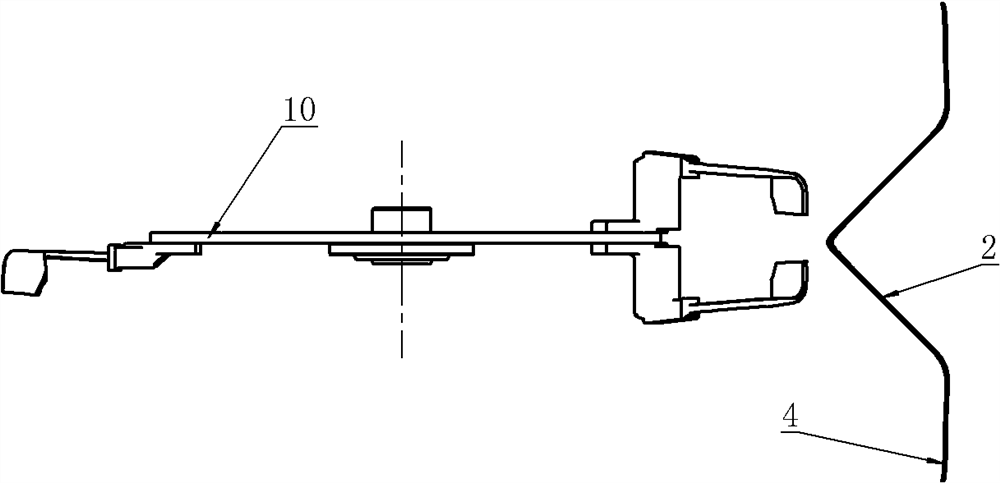

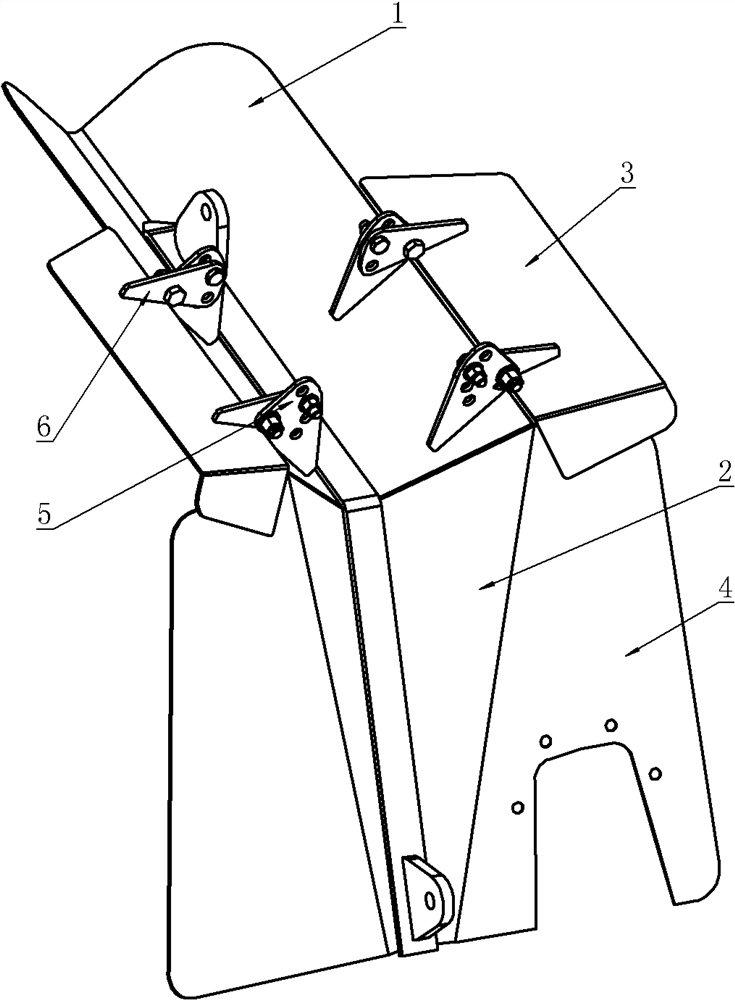

[0024] Such as Figure 1 to Figure 4 As shown, the present invention discloses a rear-mounted ditching machine soil divider. The soil divider is composed of two soil divider boards 1 and fenders 2 with different cross-sections. The whole piece of material is bent and made, and the cross-section is V-shaped when viewed from the front and rear; the fender 2 is located in front of the cutter head 10, and is also made of a whole piece of material bent. From a top view, the fender 2 The middle part of the cross-section is V-shaped, the V-shaped angle is small at the top and large at the bottom, and the depth of the V-shape is deep at the top and shallow at the bottom; The axial direction of the trencher cutterhead 10 is approximately parallel; the upper end of the V-shaped cross-section of the fender 2 is at the same angle as the V-shaped cross-section at the front end of the connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com