A constant torque control method of ecm motor applied to fan system

A fan system and control method technology, applied in the direction of single motor speed/torque control, etc., can solve the problems that affect the user's air volume requirements, affect the user's quiet experience, and low motor speed, so as to improve user experience and improve user experience Experience, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

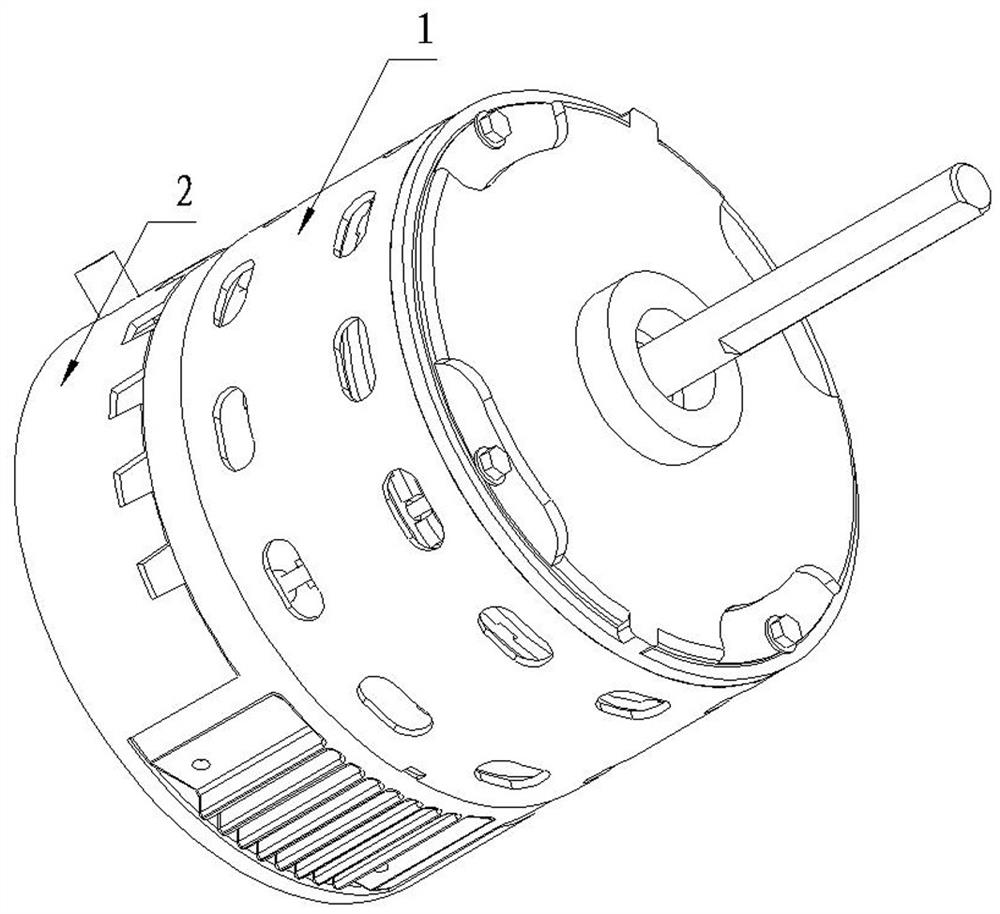

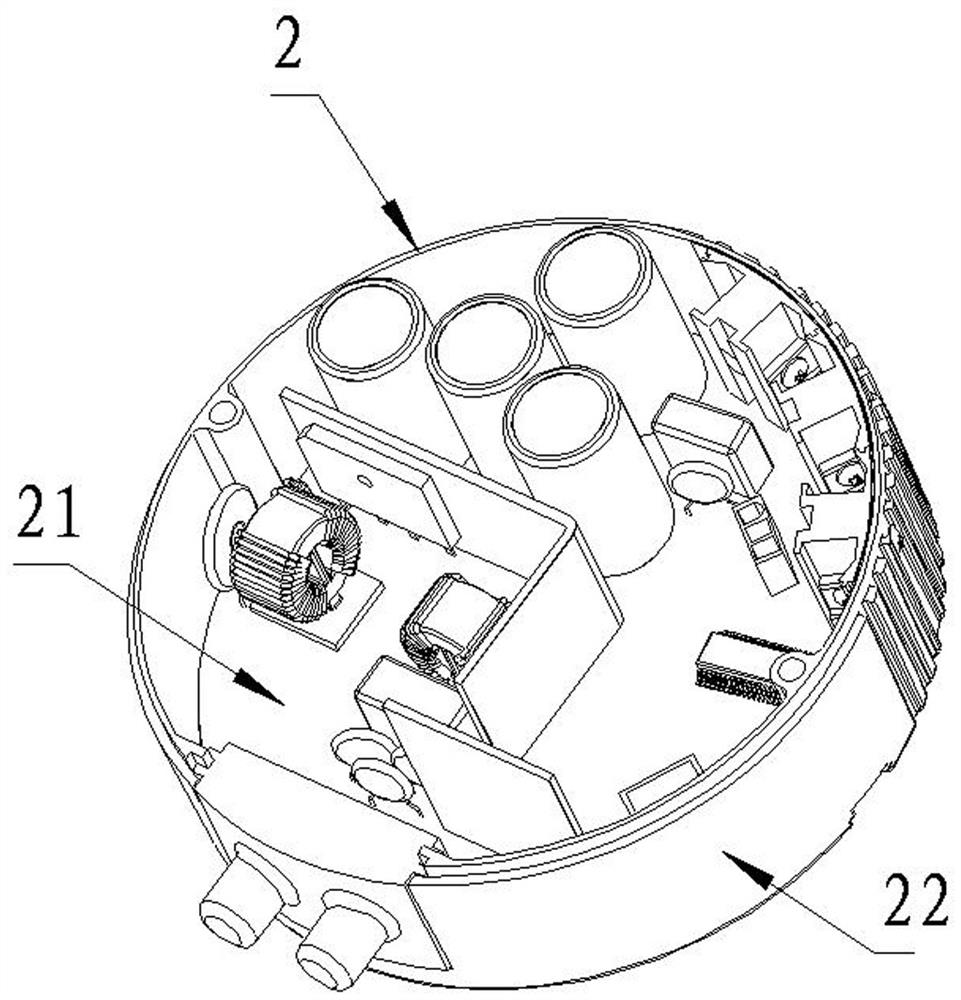

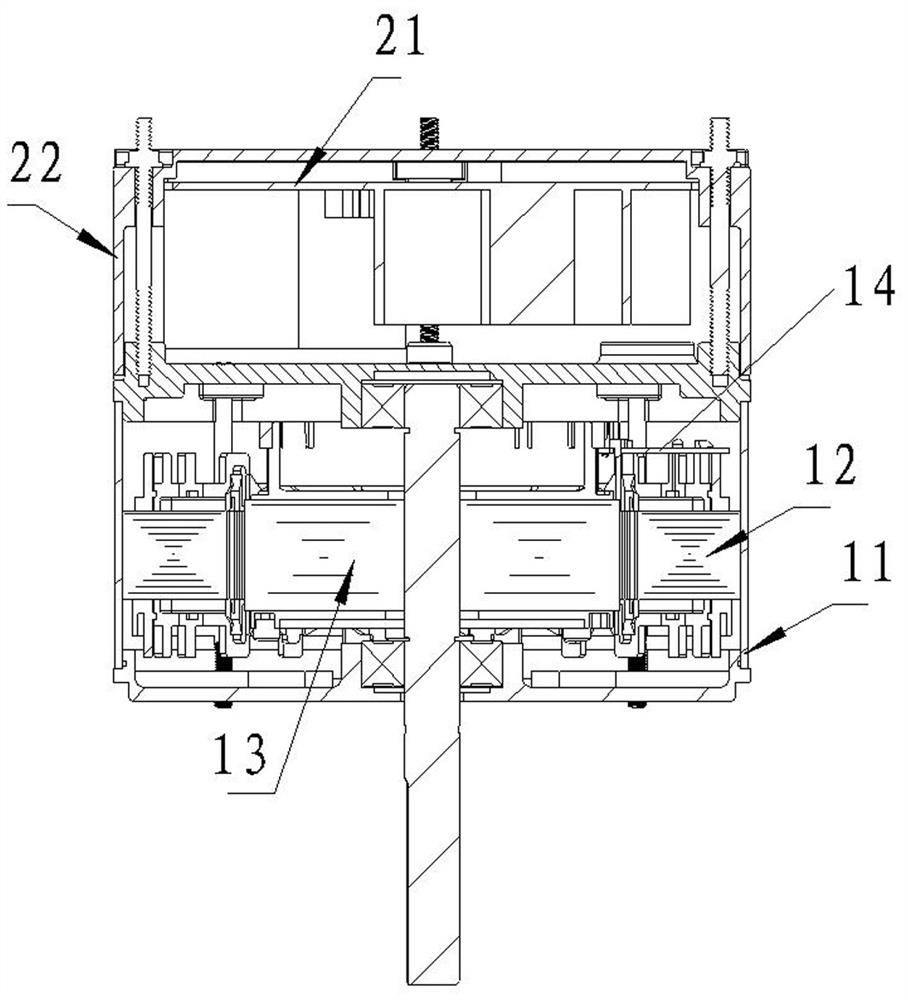

[0030] like figure 1 , figure 2 , image 3 As shown, the ECM motor usually consists of a motor controller 2 and a motor unit 1. The motor unit 1 includes a stator assembly 12, a rotor assembly 13 and a casing assembly 11. The stator assembly 13 is mounted on the casing assembly 11, and the motor The single unit 1 is equipped with a Hall sensor 14 for detecting the position of the rotor, the rotor assembly 13 is assembled inside or outside the stator assembly 12, and the motor controller 2 includes a control box 22 and a control circuit board 21 installed in the control box 22. The circuit board 21 generally includes a power supply circuit, a microprocessor, a bus current detection circuit, an inverter circuit and a rotor position measurement circuit 15 (ie, a Hall sensor). Input to the microprocessor, the busbar current d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com