Sliding block type variable-diameter plunger and using method thereof

A variable and plunger technology, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., to achieve the effect of solving technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

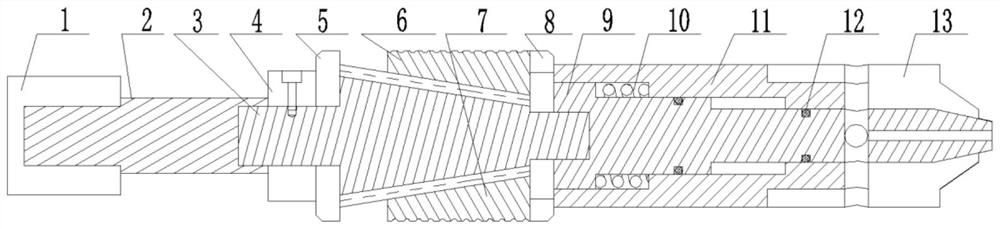

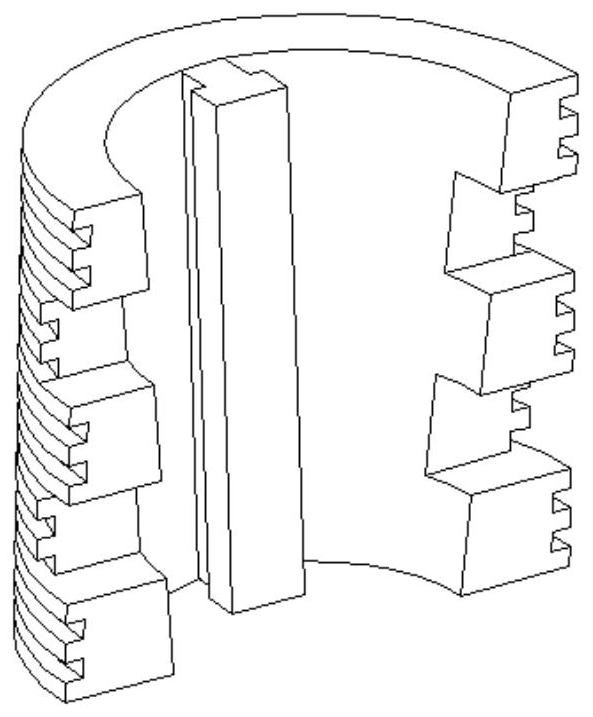

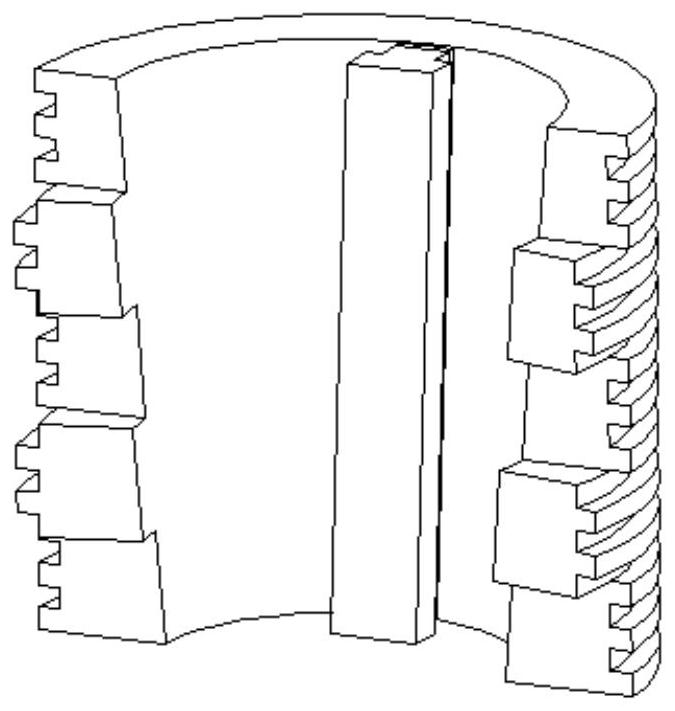

[0023] A slider-type variable-diameter plunger, including an upper connecting body 3, an upper anti-collision ring 5, an upper staggered tooth 6, a lower staggered tooth 7, a lower anti-collision ring 8, a lower connecting body 9, a piston 11 and a piston end cap 13. The upper part of the upper connecting body 3 adopts a columnar structure with a rectangular longitudinal section, the middle part of the upper connecting body 3 adopts a conical structure with an inverted isosceles trapezoidal longitudinal section, and the lower part of the upper connecting body 3 adopts a columnar structure with a rectangular longitudinal section , the upper anti-collision ring 5 and the lower anti-collision ring 8 are respectively sleeved on the head and tail ends of the middle part of the upper connecting body 3, T-shaped grooves are symmetrically opened on both sides of the outer wall of the middle part of the upper connecting body 3, and the upper staggered teeth 6 and The inner wall of the l...

Embodiment 2

[0025] On the basis of the first embodiment, a lock nut 4 is fixed on the outer wall of the upper connecting body 3 above the upper anti-collision ring 5 to prevent the upper anti-collision ring 5 from loosening and shifting.

[0026] The inner wall of the upper staggered teeth 6 and the lower staggered teeth 7 adopts a tapered surface matched with the middle part of the upper connecting body 3, and a staggered tooth-shaped plug-in structure is formed at the edges of the upper staggered teeth 6 and the lower staggered teeth 7, so as to To achieve the purpose of connecting the upper staggered teeth 6 and the lower staggered teeth 7 , spiral grooves are uniformly arranged on the outer walls of the upper staggered teeth 6 and the lower staggered teeth 7 .

Embodiment 3

[0028] On the basis of the second embodiment, the outer wall of the head end of the upper connecting body 3 is threadedly connected to the inner wall of the tail end of the fishing head connecting rod 2 , and the outer wall of the head end of the fishing head connecting rod 2 is threadedly connected to the inner wall of the tail end of the fishing head 1 .

[0029] A sealing ring 12 is provided at the sealing place between the outer wall of the lower connecting body 9 and the inner wall of the piston 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com