A self-propelled environmental protection plant

An environmental protection, self-propelled technology, applied in the directions of heat preservation, transportation and packaging, roofing, etc., can solve the problems such as the inability to meet the space requirements of the rocket workshop, the complex transmission structure of the power system, and the difficulty in finding traction vehicles, etc., to improve the overall utilization rate. , The effect of stable oil pressure and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below through specific examples, so as to make the technical solutions of the present invention easier to understand and grasp, rather than limiting the present invention.

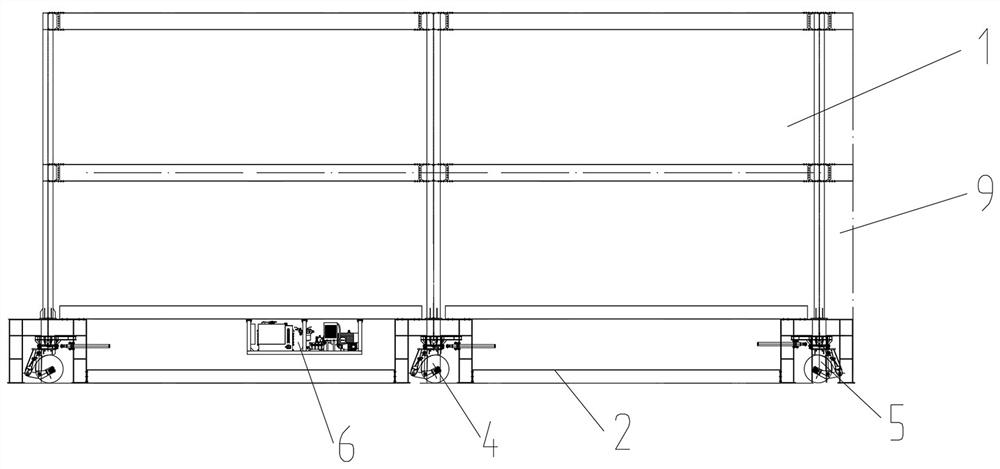

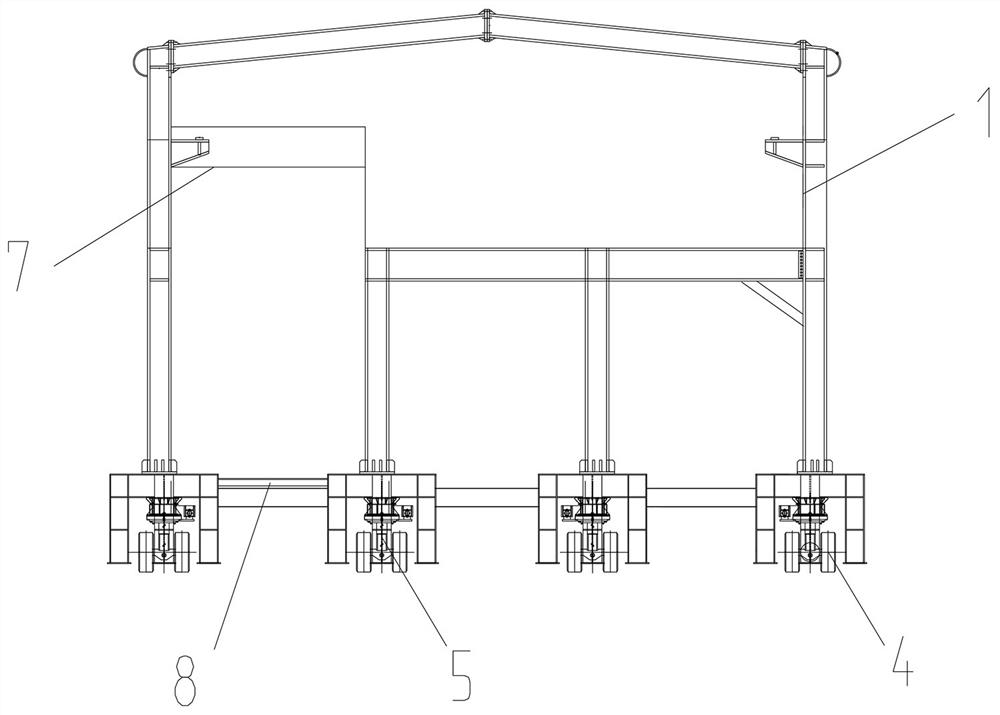

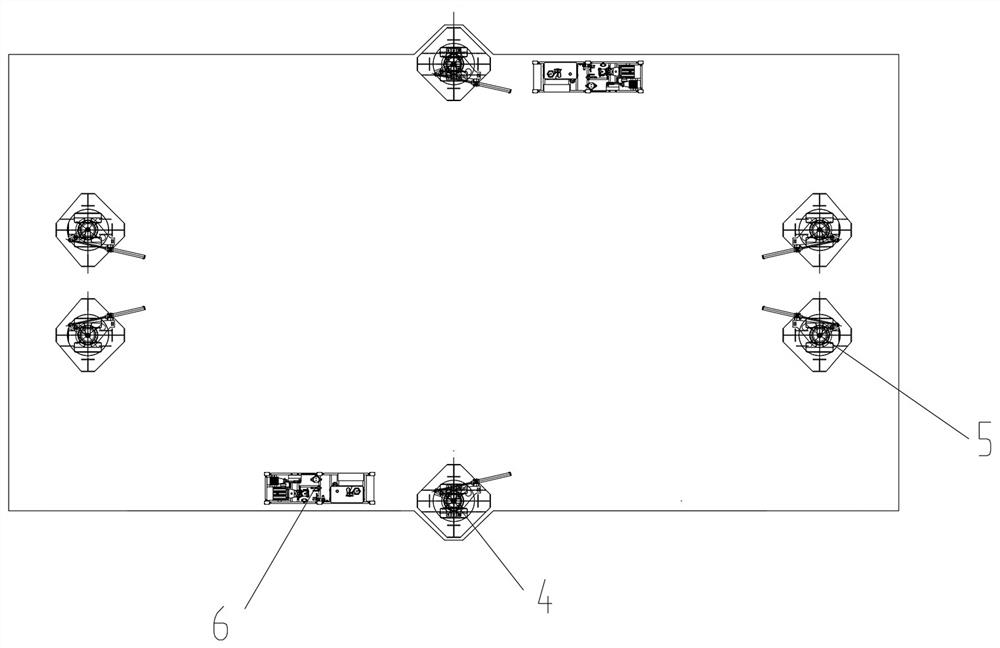

[0036] refer to Figure 1 to Figure 4, a self-propelled environmental protection workshop, including a heat preservation shed 1, a frame 2, a suspension assembly 3, a drive axle 4, a driven axle 5, a hydraulic power system 6, and an air conditioning system. In order to adjust the temperature in the heat preservation shed 1; the heat preservation shed 1 is fixed on the top of the frame 2, and the frame 2 is respectively installed with two drive axles 4 and four driven axles 5 through six suspension assemblies 3, and the drive axles 4 are symmetrically distributed On both sides of the middle of the frame 2, the drive plant moves, the driven axles 5 are symmetrically distributed in the middle of the front end and the middle of the rear end of the frame 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com