Thermal response composite proton membrane as well as preparation method and application thereof

A proton membrane, thermal response technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing a thermoresponsive composite proton membrane, comprising the following steps:

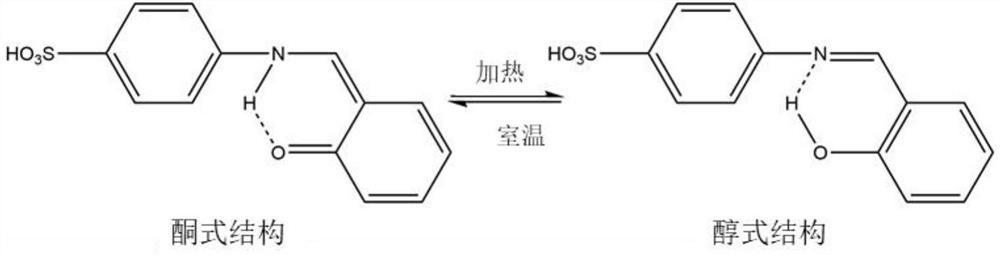

[0023] (1) Mix the zirconium-based metal-organic framework composite material loaded with 4-[(2-hydroxybenzyl)amino]benzenesulfonic acid with water to obtain a suspension; the loaded 4-[(2-hydroxybenzyl)amino A zirconium-based metal-organic framework composite material of ]benzenesulfonic acid is prepared from 4-[(2-hydroxybenzyl)amino]benzenesulfonic acid and a zirconium-based metal-organic framework material;

[0024] (2) mixing polyvinyl alcohol solution and poly(2-acrylamide-2-methyl-1-propanesulfonic acid) solution to obtain a mixed solution;

[0025] (3) adding dropwise the suspension obtained in the step (1) to the mixed solution obtained in the step (2), and then adding glutaraldehyde to carry out a cross-linking reaction to obtain a cross-linked product;

[0026] (4) casting the cross-linked product obtained in the step (3) into a mold ...

Embodiment 1

[0085] Preparation method of heat-responsive composite proton membrane

[0086] (1) Mix 0.03 g of zirconium-based metal-organic framework composite material loaded with 4-[(2-hydroxybenzyl)amino]benzenesulfonic acid and 4 mL of distilled water for 0.5 hours to obtain a suspension;

[0087] The zirconium-based metal-organic framework composite material loaded with 4-[(2-hydroxybenzyl)amino]benzenesulfonic acid is prepared from 4-[(2-hydroxybenzyl)amino]benzenesulfonic acid and zirconium-based metal-organic framework materials Obtain; 4-[(2-hydroxybenzyl)amino]benzenesulfonic acid and zirconium-based metal-organic framework in the zirconium-based metal-organic framework composite material loaded with 4-[(2-hydroxybenzyl)amino]benzenesulfonic acid The mass ratio of materials is 0.29:1;

[0088] The preparation method of the zirconium-based metal-organic framework material is:

[0089] Mix 121.5mg of zirconium source zirconium oxychloride, 53mg of organic ligand trimesic acid, 6...

Embodiment 2

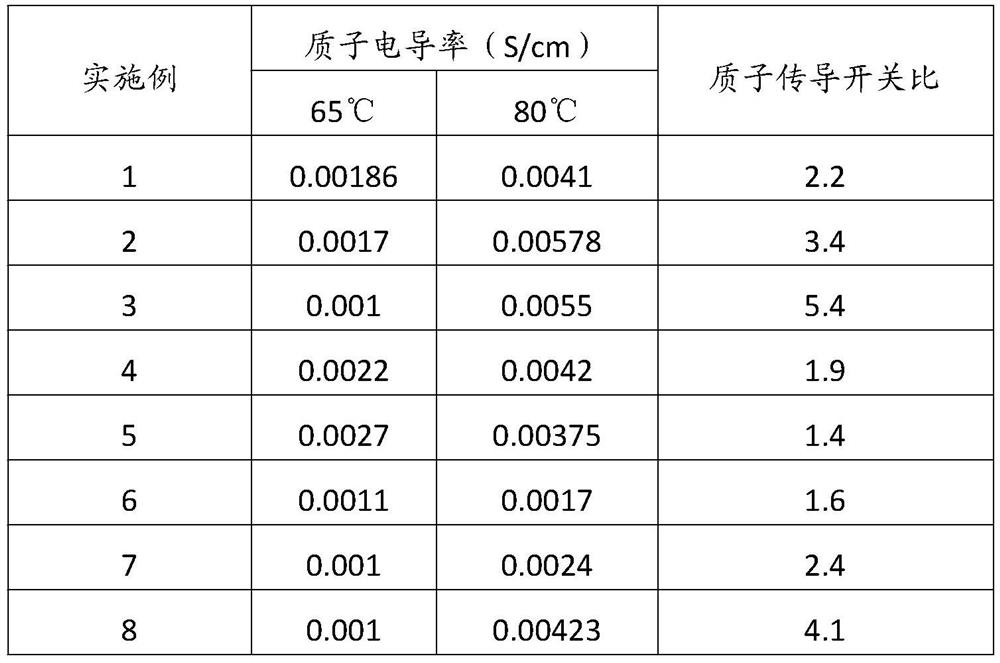

[0100] The thermally responsive composite proton membrane was prepared according to the method of Example 1, and the proton conductivity and the proton conduction switch ratio of the prepared thermally responsive composite proton membrane were detected by the same method. The specific results are shown in Table 1;

[0101] Different from Example 1, the quality of the zirconium-based metal-organic framework composite material loaded with 4-[(2-hydroxybenzyl)amino]benzenesulfonic acid in the step (1) is 60 mg; the step (3) The mass of zirconium-based metal-organic framework composites loaded with 4-[(2-hydroxybenzyl)amino]benzenesulfonic acid in medium suspension is equal to the mass of polyvinyl alcohol and poly(2-acrylamide-2-methyl-1 - propanesulfonic acid) 20% of the total mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com