Preparation method and preparation equipment of selenium-rich foliar fertilizer for rice

A selenium-enriched foliage fertilizer and a technology for its production method are applied in the field of production methods and equipment based on selenium-enriched foliage fertilizer for rice, which can solve the problems of insufficient stability of the effect of selenium-enriched foliar fertilizer for rice and achieve enhanced Persistence and adaptability, enhanced nutrient uptake, effects on growth requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

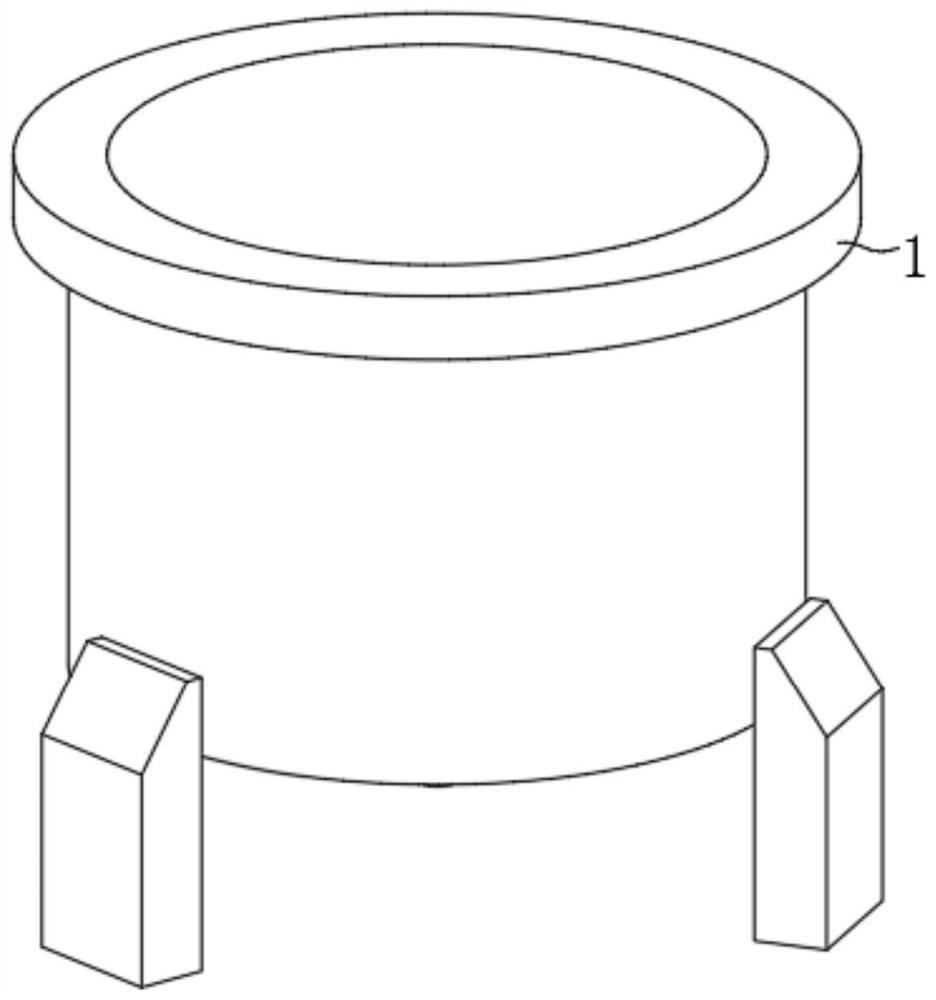

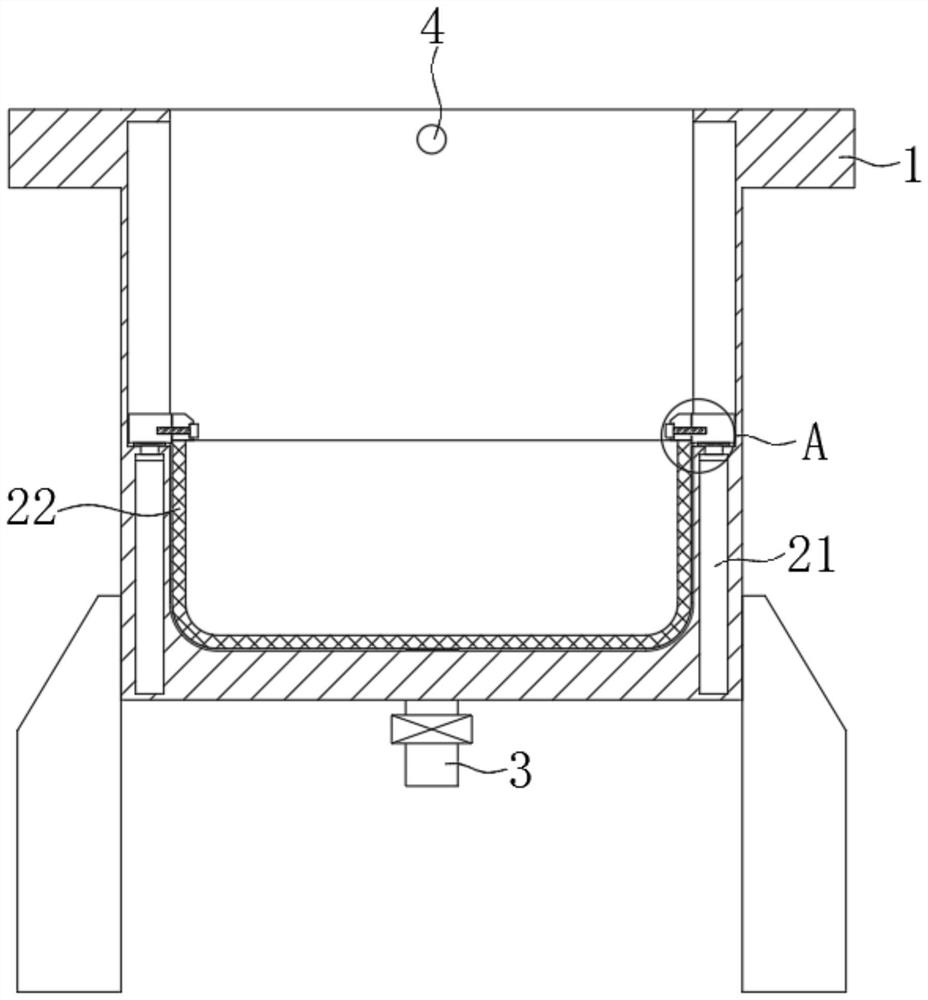

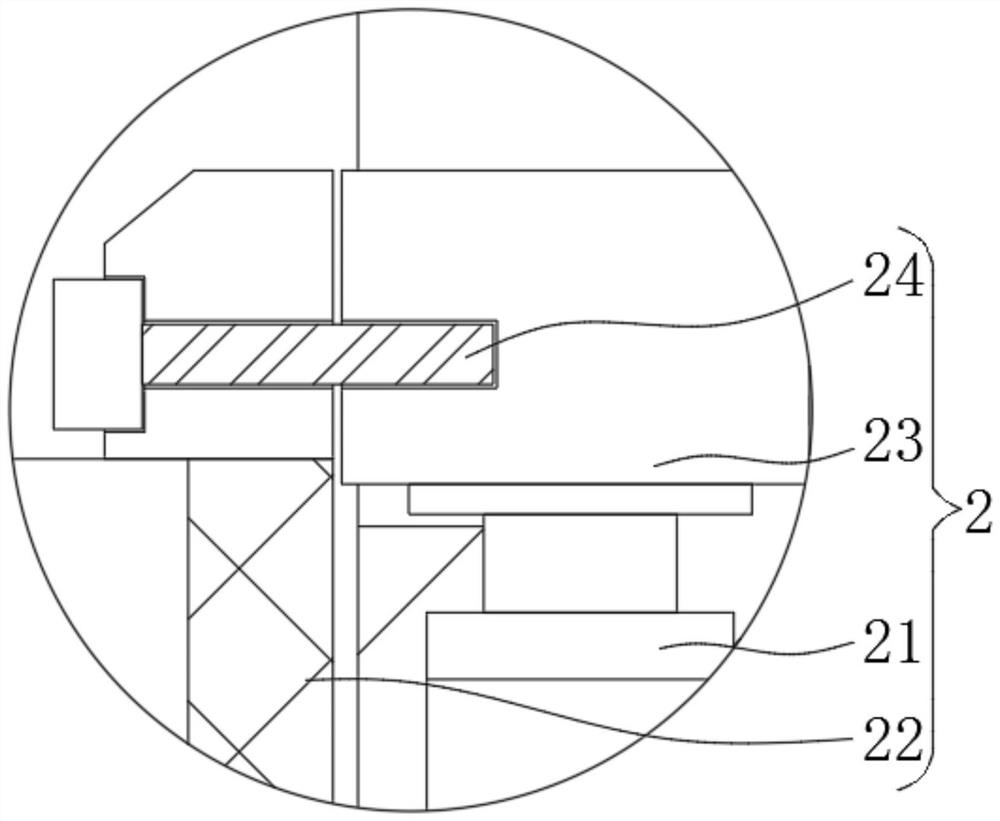

[0037] Please refer to figure 1 , figure 2 , image 3 ,in, figure 1 The schematic structural representation of the selenium-enriched foliage fertilizer production equipment based on rice provided by the invention; figure 2 for figure 1 The schematic diagram of the internal structure of the main body shown;

[0038] image 3 for figure 2 The enlarged schematic diagram of part A is shown. Based on the preparation method of selenium-enriched foliage fertilizer for rice and the production equipment thereof, the method comprises the following steps:

[0039] S1. First weigh 30g of sodium selenite, 25g of potassium chloride, 10g of ammonium nitrate, 5g of potassium dihydrogen phosphate, 10g of polyaspartic acid, 12g of citric acid, 8g of boric acid, 11g of magnesium sulfate, and amino acids according to the weight of the following raw materials. 2g, 0.5g of surfactant, 3g of organic solvent, 40g of mixed plants with selenium properties;

[0040] Wherein the surfactant is...

no. 2 example

[0057] Based on the first embodiment of the present invention, a method for making a selenium-rich foliar fertilizer based on rice and its production equipment, the second embodiment of the present invention provides another method for making a selenium-rich foliar fertilizer based on rice and its production equipment. Manufacturing equipment, wherein the second embodiment does not hinder the independent implementation of the technical solution of the first embodiment.

[0058] Specifically, the present invention provides another manufacturing method based on selenium-enriched foliage fertilizer for rice and its manufacturing equipment. The difference is that:

[0059] S1. First weigh 40g of sodium selenite, 35g of potassium chloride, 20g of ammonium nitrate, 9g of potassium dihydrogen phosphate, 16g of polyaspartic acid, 15g of citric acid, 12g of boric acid, 15g of magnesium sulfate, and amino acid according to the weight of the following raw materials. 6g, 1.2g of surfactan...

no. 3 example

[0068] Based on the first embodiment of the present invention, a method for making a selenium-rich foliage fertilizer for rice and its production equipment, the third embodiment of the present invention provides another method for making a selenium-rich foliar fertilizer based on rice and its production equipment. Manufacturing equipment, wherein the third embodiment does not hinder the independent implementation of the technical solution of the first embodiment.

[0069] Specifically, the present invention provides another manufacturing method based on selenium-enriched foliage fertilizer for rice and its manufacturing equipment. The difference is that:

[0070] S1. First weigh 35g of sodium selenite, 30g of potassium chloride, 15g of ammonium nitrate, 7g of potassium dihydrogen phosphate, 13g of polyaspartic acid, 14g of citric acid, 10g of boric acid, 13g of magnesium sulfate, and amino acid according to the weight of the following raw materials. 4g, 0.8g of surfactant, 4g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com