Multi-working-condition buoyancy adjusting device and adjusting method

A technology of buoyancy adjustment and adjustment method, which is applied in the direction of transportation and packaging, special-purpose vessels, underwater operation equipment, etc., can solve the problems of large axial size of piston cylinder, small adjustable range, unfavorable device balance and stability, etc., to achieve Strong practicability, increased buoyancy adjustment range, beneficial to balance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

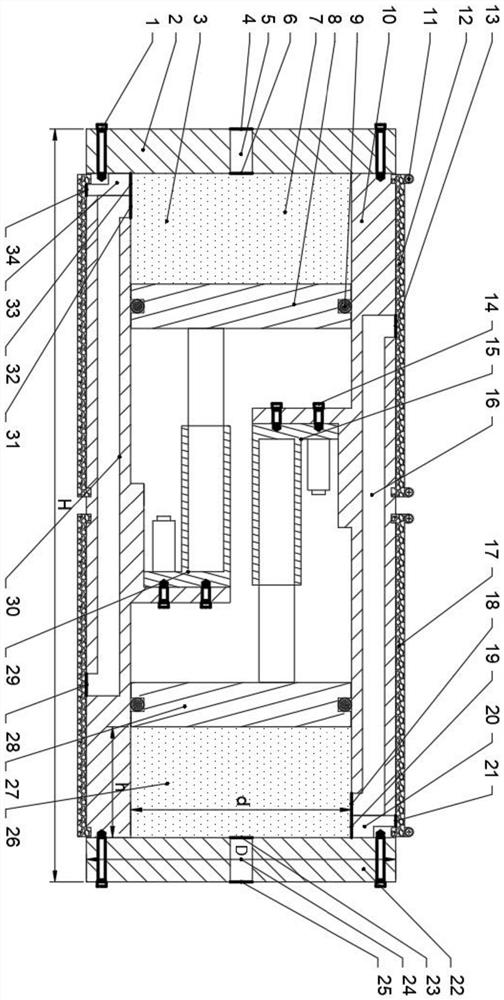

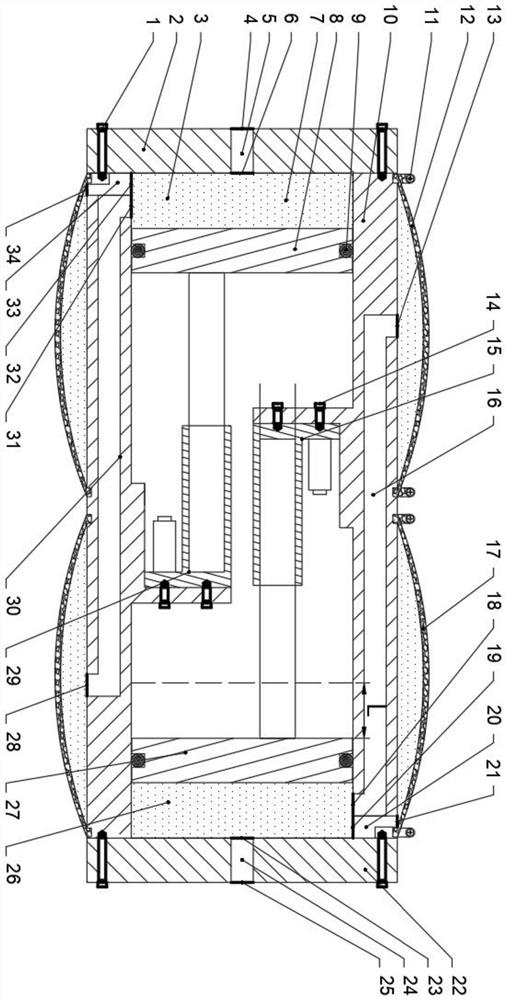

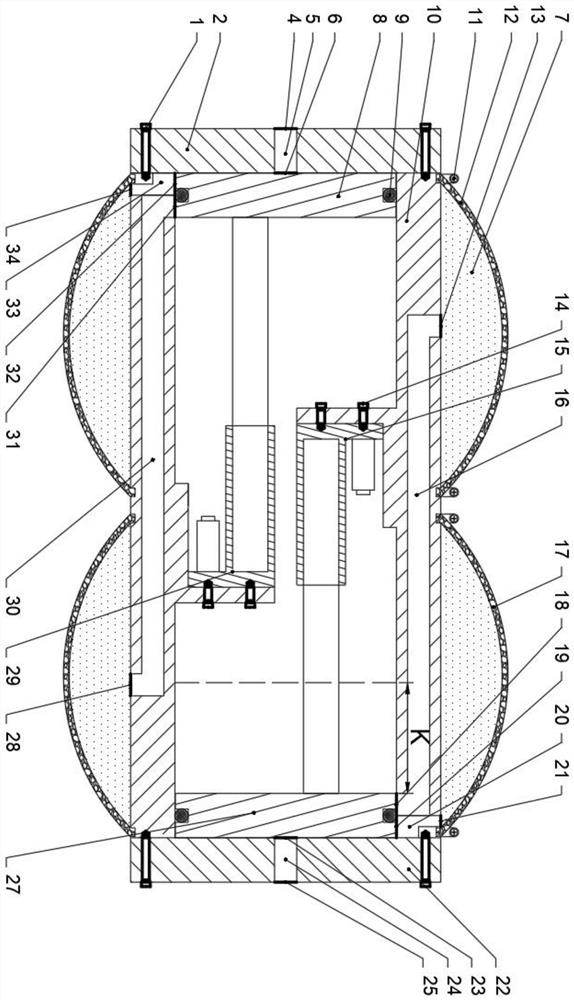

[0073] Such as Figure 1 to Figure 9 As shown, the multi-condition buoyancy adjustment device of the present invention includes a cabin body 10, a thrust assembly, a cavity assembly and a rubber bladder assembly; the cavity assembly includes a first cavity 3 and a second cavity 26; the rubber bladder assembly includes a first rubber The bladder 12 and the second rubber bladder 17; the thrust assembly includes a first thrust assembly and a second thrust assembly; wherein the first thrust assembly includes a first electric push rod 15 and a second piston 27; the second thrust assembly includes a second electric push rod 29 and the first piston 8.

[0074] The rubber bladder assembly is fixed with the cabin body 10 by the clamp 11, and the oil is stored in the first cavity 3 and the second cavity 26. Wherein the left end cover 2 and the right end cover 22 are fixed on the cabin body 10 by the first screw 1; the first electric push rod 15 and the second electric push rod 29 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com