Gas ultrasonic flowmeter applied to large pipe diameter

An ultrasonic and flowmeter technology, which is used in liquid/fluid solid measurement, flow measurement/mass flow measurement, and measurement devices, etc., can solve the problems that flowmeters cannot meet the use of complex pipelines, and the pulsating flow reaction of choke flow is large. The rectification effect is good, the installation environment and manufacturing cost are reduced, and the effect of reducing the manufacturing and installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

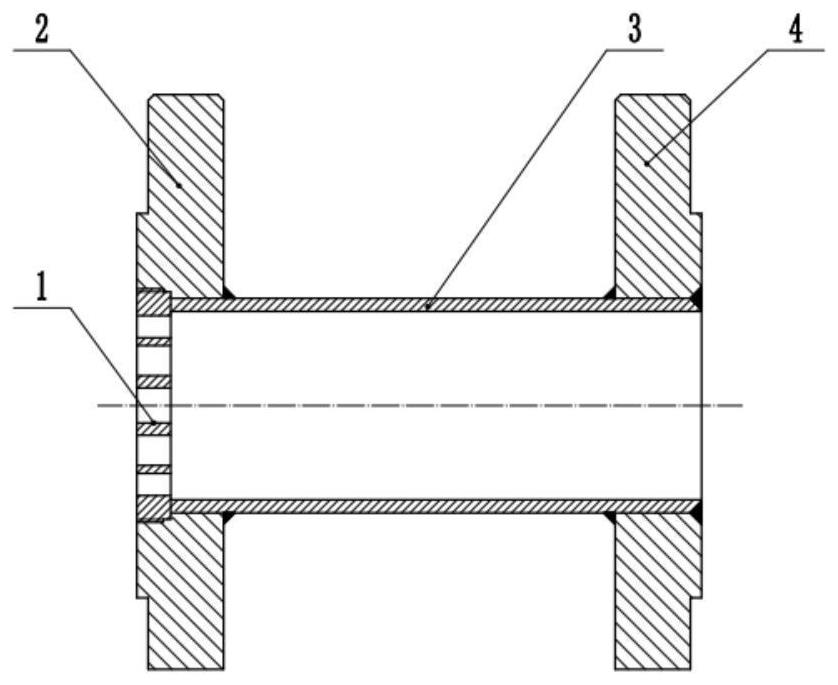

[0057] like figure 1 As shown, a gas ultrasonic flowmeter applied to a large pipe diameter includes an ultrasonic metering unit and a rectifier located at the inlet end of the ultrasonic metering unit;

[0058] The rectifier includes a rectifier plate 1, a left flange 2, a seamless steel pipe 3 made of stainless steel and a right flange 4;

[0059] The left flange 2 is used to connect the external gas pipeline; the right flange 4 is connected with the ultrasonic metering unit flange;

[0060] The left flange 2 is provided with a stepped through hole;

[0061] The small end of the step through hole of the left flange 2 is sleeved on one end of the seamless steel pipe 3 and the step surface is flush with the end surface of the seamless steel pipe 3; The end face of the seam steel pipe 3 is flush;

[0062] The rectifier plate 1 is arranged on the big end of the step through hole of the left flange 2 and the outer surface is flush with the end face of the big end of the step th...

specific Embodiment 2

[0077] D=100mm.

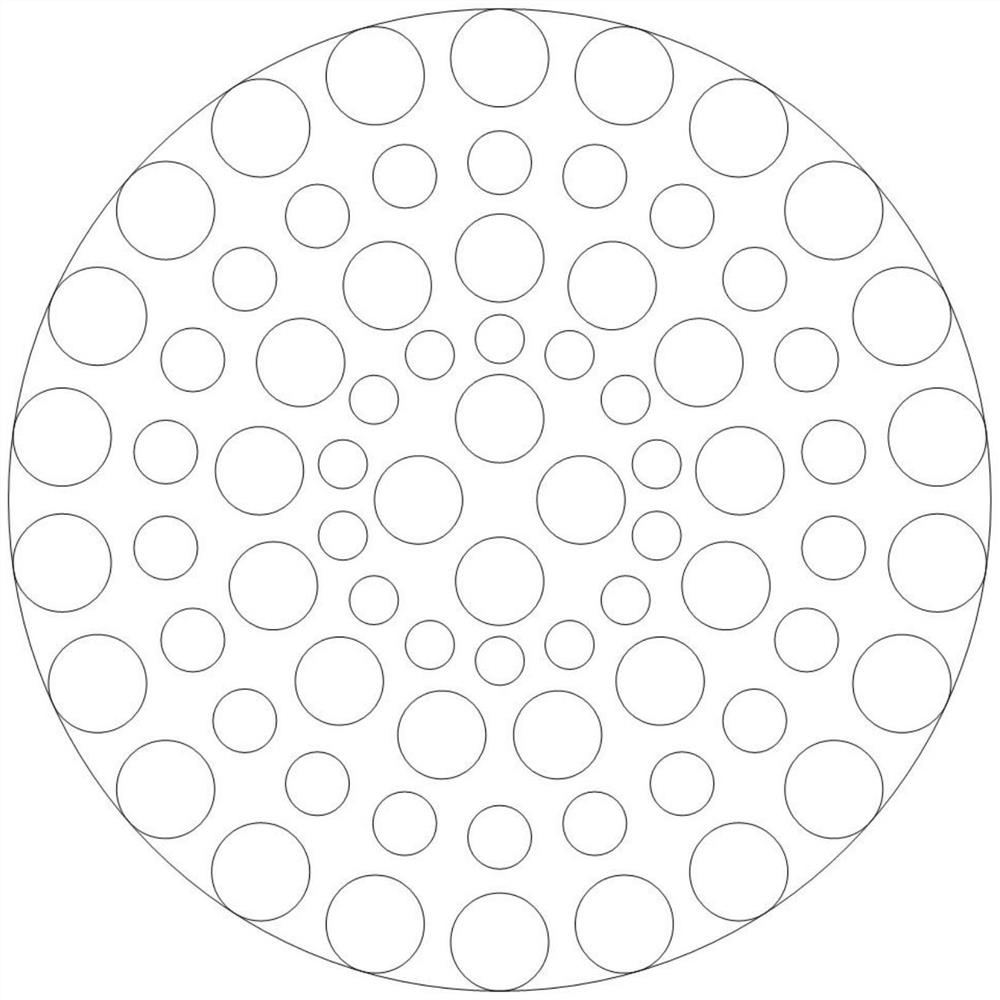

[0078] like Figure 4 As shown, the surface of the rectifying plate 1 is provided with a first index circle with a diameter of 87mm, a second index circle with a diameter of 56mm, and a third index circle with a diameter of 24mm from the outside to the inside.

[0079] The centers of the first index circle, the second index circle and the third index circle are located at the same position.

[0080] like figure 2 As shown, there are 16 diameters d evenly arranged on the first indexing circumference with a diameter of 87mm 11 =13mm hole;

[0081] There are 10 diameters d evenly arranged on the second indexing circumference with a diameter of 56mm 22 =12mm hole;

[0082] Four diameters d are evenly arranged on the third indexing circumference with a diameter of 24mm 33 =14mm hole.

[0083] The rest of the structure is the same as that of the first embodiment.

Embodiment 2

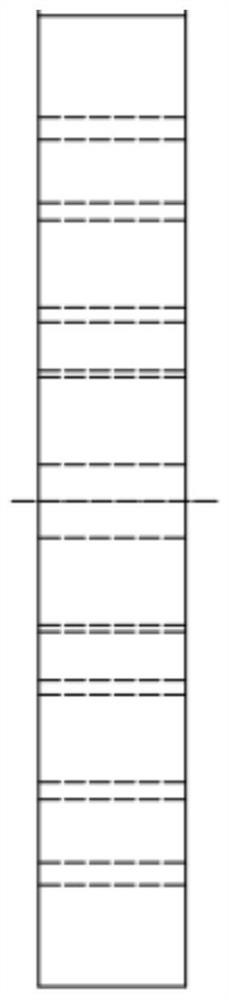

[0084] The use effect of embodiment 2 and Image 6 shown consistent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com