Method and device for simultaneously detecting surface shapes and thickness distribution of inner wall and outer wall of thin-wall rotary body

A technology of thin-wall rotation and thickness distribution, applied in the field of precision measurement, to achieve the effect of ensuring measurement accuracy and coordinate consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

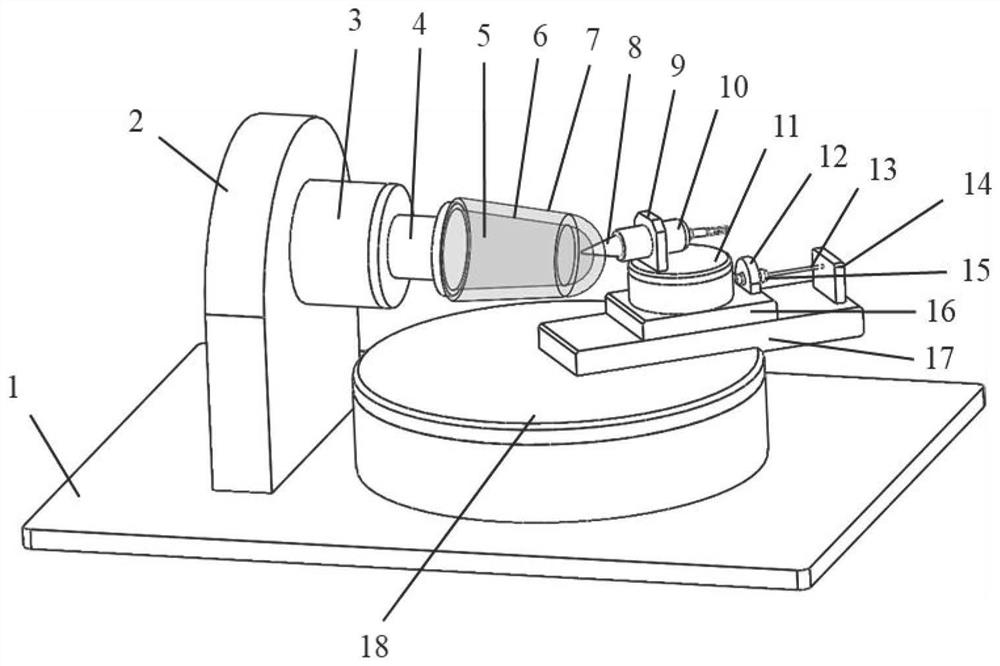

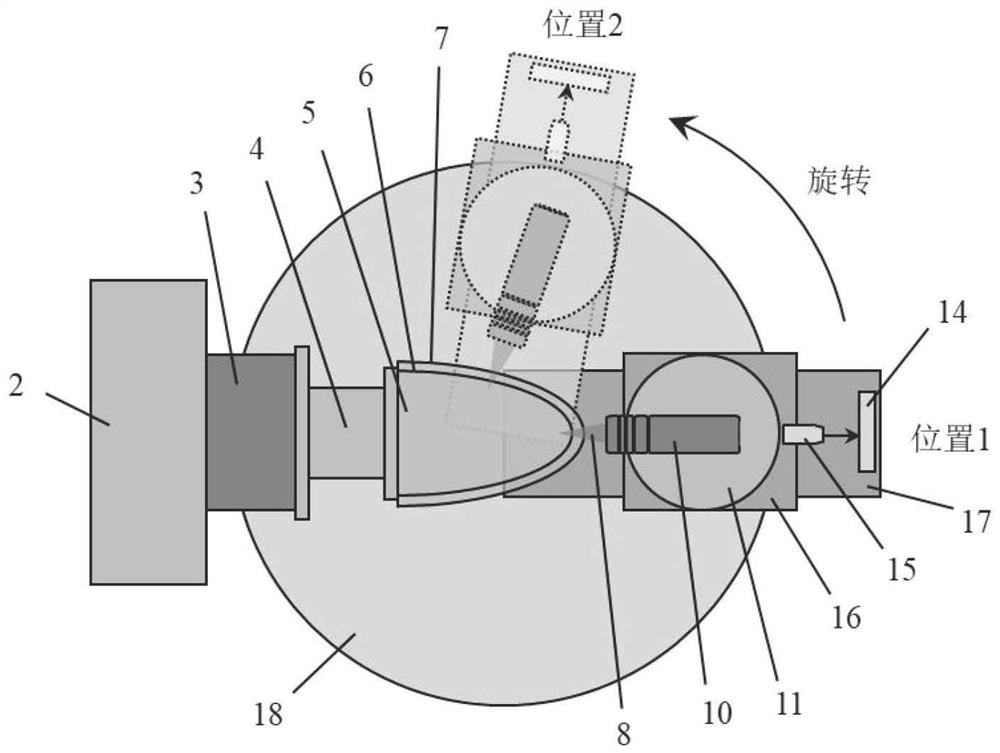

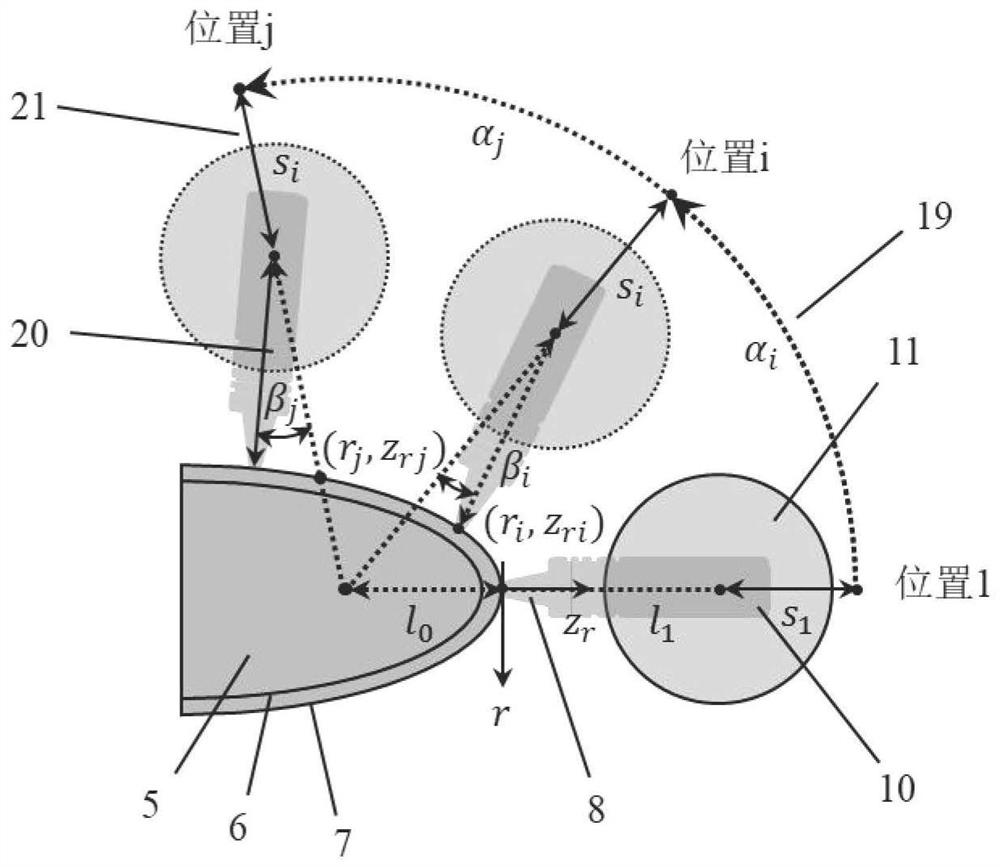

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0047] The present invention proposes a measuring device and method based on a sensor capable of measuring multiple surfaces such as a spectral confocal probe to realize the surface shape and thickness distribution of the inner and outer walls of a thin-walled shell. The axis drives the spectral confocal probe to perform profiling scanning motion along the surface of the thin-walled shell, and the single-sided thickness measurement avoids the mechanical interference problem of the through-beam thickness measurement, and simultaneously collects the thin-walled shell during the scanning process. The position and thickness information of the inner and outer walls in the body can ensure the consistency of the coordinates of the detection data in space, so as to realize the high-precision and rapid detection of the shape and thickness distribution of the inner and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com