Steel column mounting method

An installation method and technology of steel columns, applied in the processing of building materials, construction, scaffolding accessories, etc., can solve the problems of delayed installation of steel columns, long erection period, cumbersome erection of operation platforms, etc., and achieve stable installation and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

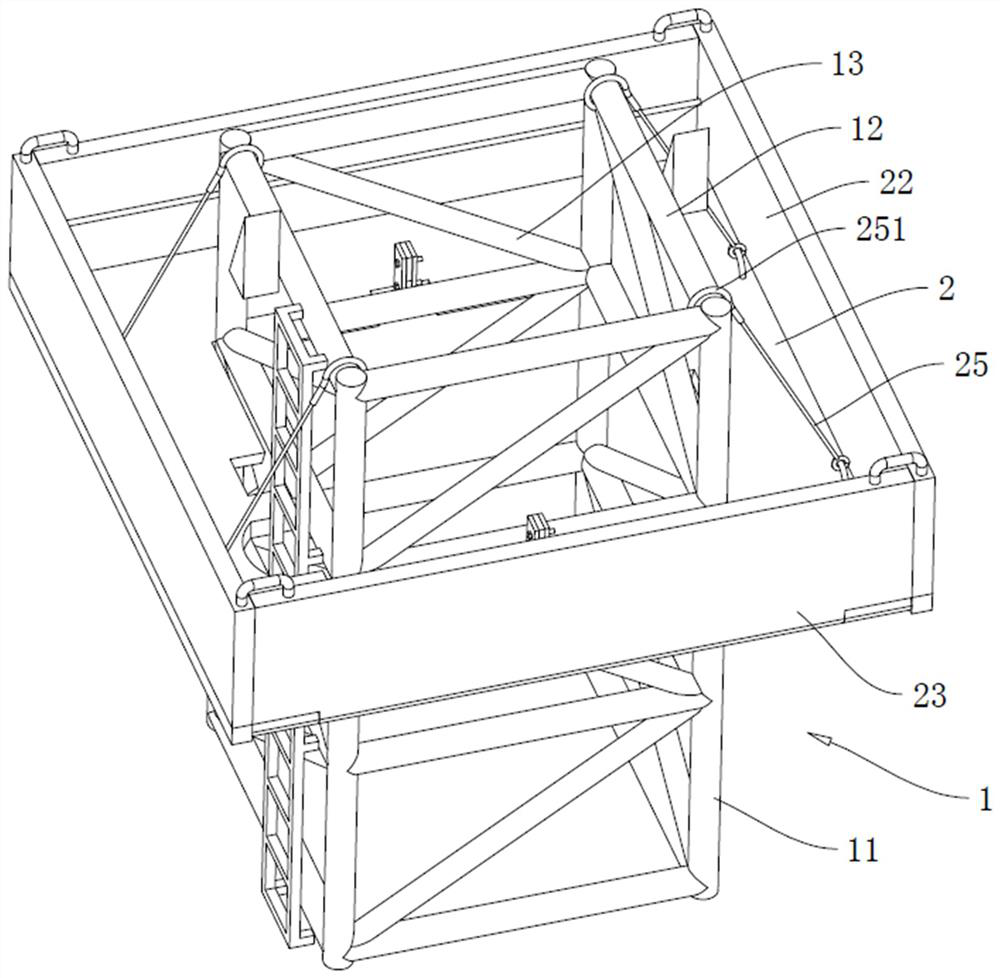

[0036] The following is attached Figure 1-5 The application is described in further detail.

[0037] The embodiment of the present application discloses a method for installing a steel column. The steel column installation method includes the following steps:

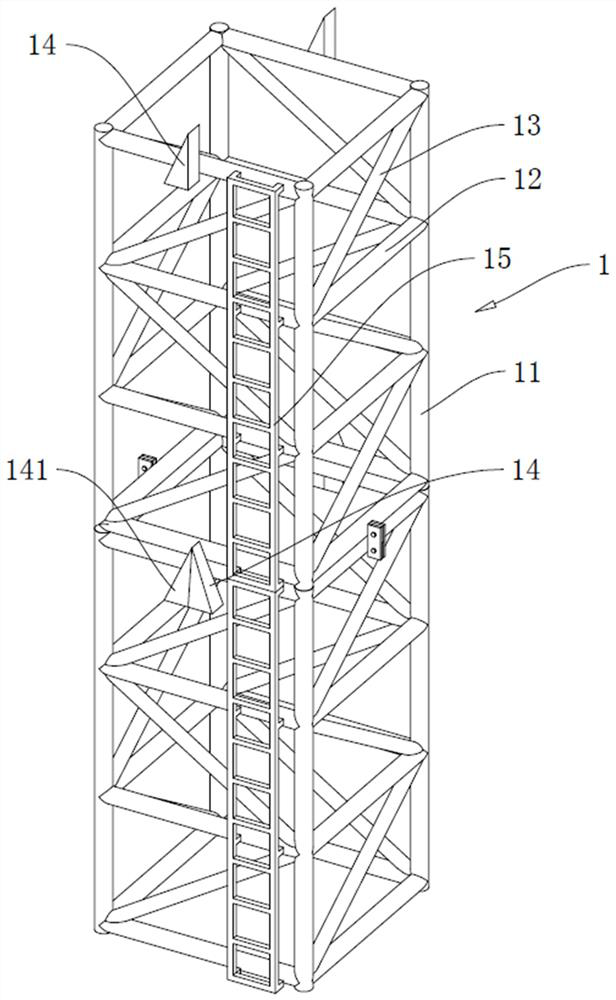

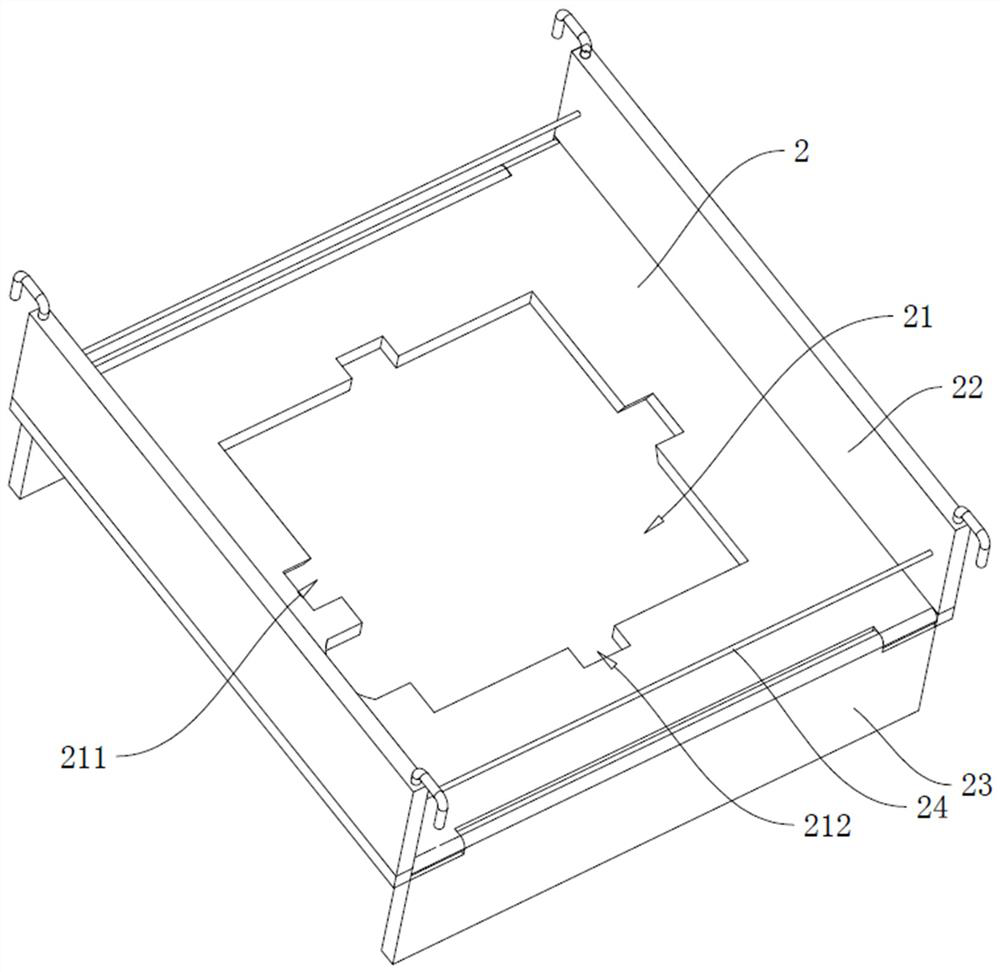

[0038] S1. Assembled steel column unit 1: refer to figure 1 , first install the steel column form designed in the drawings to assemble the steel column unit 1, the steel column unit 1 includes four round tubes 11, the four round tubes 11 are arranged in a rectangular array, and there are fixed connections between adjacent round tubes 11 A plurality of crossbars 12, and the crossbars 12 and the round pipe 11 are perpendicular to each other; two adjacent crossbars 12 along the length direction of the round pipe 11 are connected with a diagonal rod 13, and the diagonal rod 13 is arranged between the crossbar 12 and the round pipe. At the diagonal of the rectangular frame formed by 11, the oblique directions of two adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com