Tooling and method for rapid positioning and adjustment of prefabricated beam components

A technology of prefabricated beams and components, applied in building construction, building material processing, construction, etc., can solve the problems of long construction period, occupation period, labor cost, etc., and achieve the effect of reducing labor, reducing erection, and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more clearly understood, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

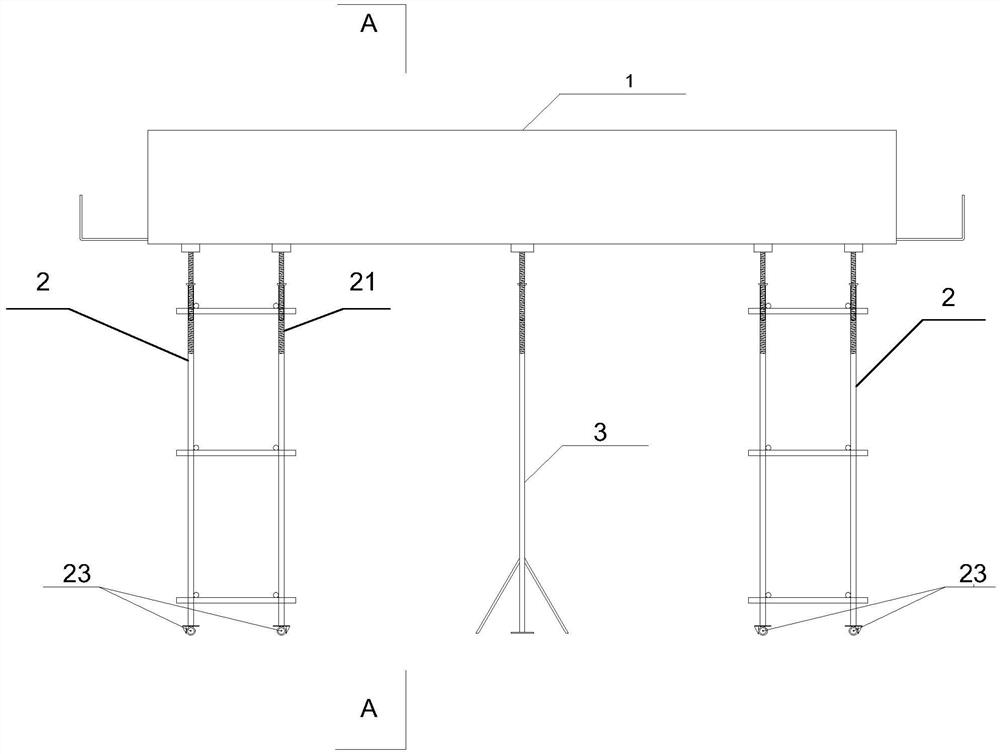

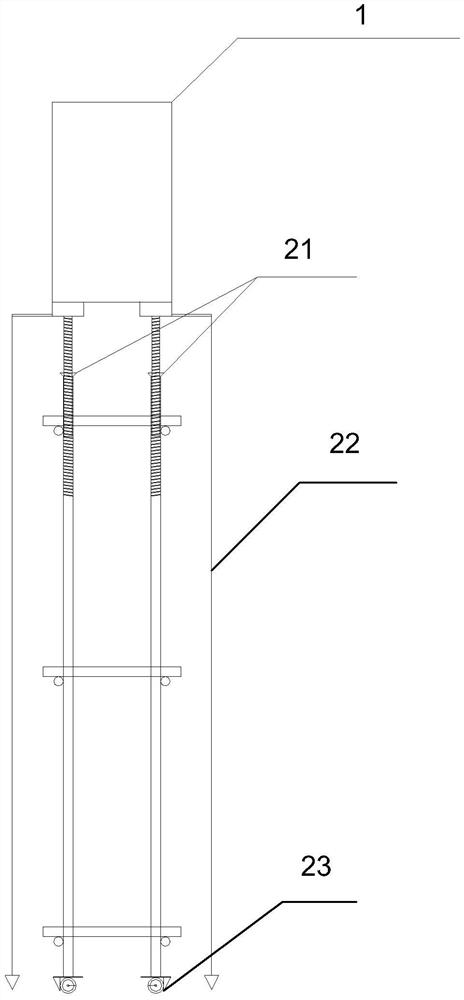

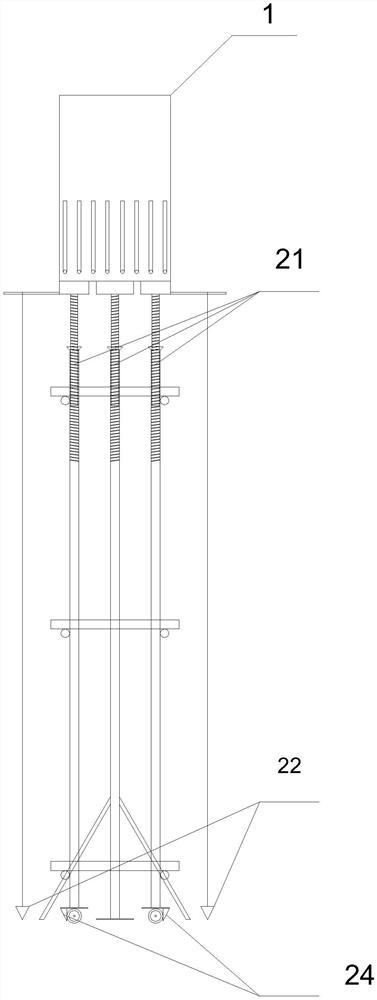

[0030] like Figures 1 to 5 As shown, the present invention provides a tool for rapid positioning and adjustment of prefabricated beam components, including:

[0031] The movable self-locking support frames 2 are respectively supported on both ends of the bottom of the prefabricated beam member 1. The top of the self-locking support frame 2 is provided with a first elevation-adjustable movable jack 21. Both sides of the top are provided with verticality control line hammers 22 that are perpendicular to the ground, and the bottom of the self-locking support frame 2 is provided with a lockable pulley 23; the locking pulley is provided with a pulley lock 24;

[0032] An adjustable tool-type support frame 3 supported between the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com