Wall tile mounting structure

A technology for installing structures and tiles, which is applied in building construction, covering/lining, construction, etc., can solve the problems of increased tile transportation costs, increased tile transportation space requirements, and tiles that cannot be stacked on top of each other, so as to reduce the risk of falling , Improve decoration efficiency and save assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

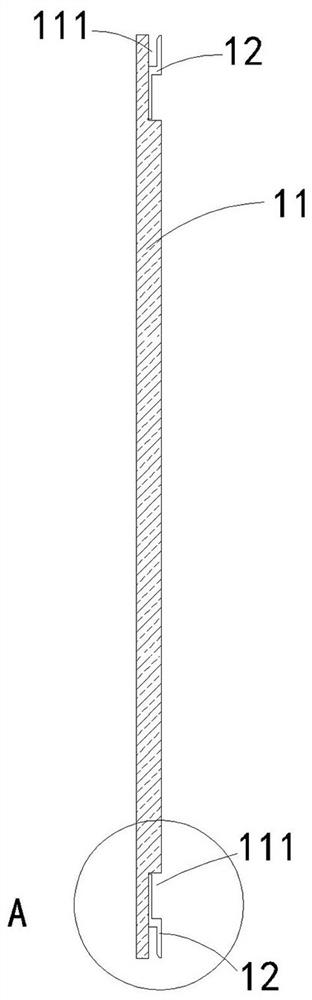

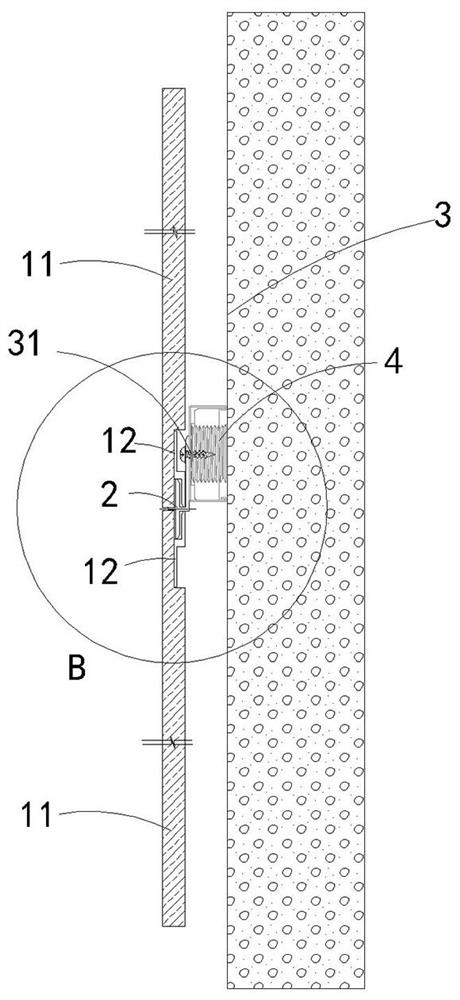

[0035] see Figure 1-4 7. This embodiment provides a wall tile installation structure, including at least two tile units and connectors 2, the number of connectors 2 is one less than the number of tile units, and all tile units are arranged in sequence along the vertical direction, A connecting piece 2 is provided between every two adjacent tile units, so that two adjacent tile units are connected through the connecting piece 2 . The tile unit and connector 2 are transported to the decoration site respectively, and the tile unit and connector 2 are assembled at the decoration site to form a wall tile installation structure, and the connector 2 is installed on the wall 3, so that the tile unit can pass through the connection. The piece 2 lays the wall surface 3 . Conventionally, a leveling piece 4 is arranged between the connecting piece 2 and the wall surface 3 in this embodiment, and the connecting piece 2 is installed on the wall surface 3 through the leveling piece 4 .

[...

Embodiment 2

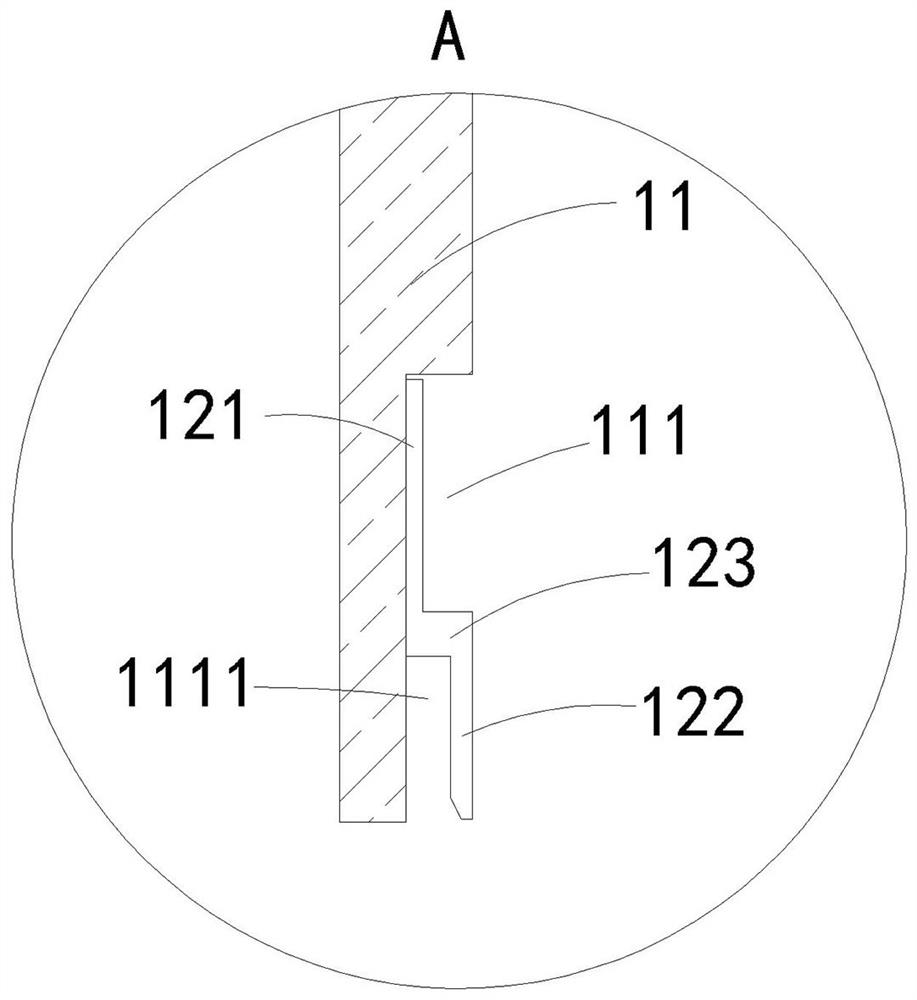

[0061] see Figure 5-7 In this embodiment, the clamping member also includes a sticking plate 121, a clamping plate 122 and a component connecting plate 123, the edge of the sticking plate 121 is fixed to the front side edge of the component connecting plate 123, and the edge of the clamping plate 122 is connected to the component connecting plate The rear side edge of 123 is fixed, and the pasting plate 121 is glued and fixed to the inner wall of the receiving groove 111 . The difference between this embodiment and Embodiment 1 is that the pasting plate 121 and the clamping plate 122 are located on the same side of the component connecting plate 123, and among the clamping components on the top of the tile unit, the pasting plate 121 and the clamping plate 122 are both located on the component connecting plate 123. Above the board 123 , among the clamping components at the bottom of the tile unit, the pasting plate 121 and the clamping plate 122 are both located below the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com