Method for conditioning excess sludge through cooperation of aluminum sludge and advanced oxidation

A technology of excess sludge and advanced oxidation, which is applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. Improved compressibility, enhanced strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

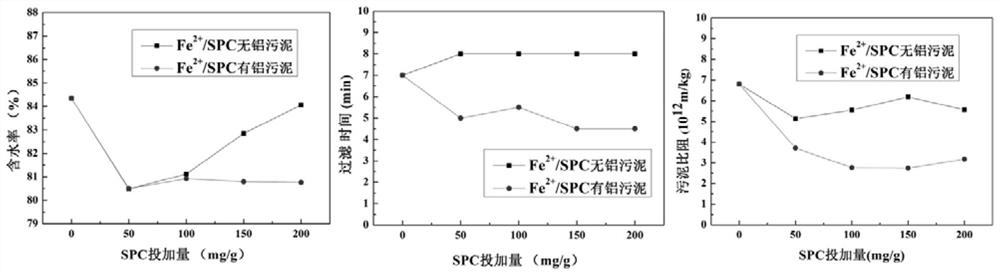

[0019] Example 1 Effect of Adding Aluminum Sludge on Sludge Dewatering Performance

[0020] The aluminum sludge was taken from the coagulated sludge of the central high-density sedimentation tank of Quehua Water Plant in Jinan City, with an aluminum content of 7.5 mg / g dry sludge; the remaining sludge was taken from the sedimentation unit of the biochemical treatment unit of the reclaimed water treatment station of Jinan University The remaining sludge in the pool; take 500 mL of the remaining sludge to be treated, and add Fe according to the amount of dry sludge 2+ (dosing amount is 20 mg / g) and SPC (dosing amount is 50 mg / g, 100 mg / g, 150 mg / g, 200 mg / g), and then add aluminum sludge (based on aluminum content , the dosage was 6 mg / g), and the one without adding aluminum sludge was used as the control.

[0021] After adding all the materials, the reaction system was obtained, and then placed in a six-connected mixer (Meiyu MY 3000-6F) for conditioning. The setting was first...

Embodiment 2

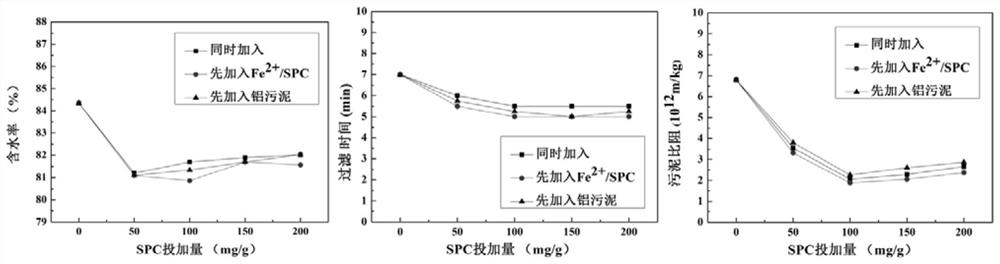

[0031] Example 2 Effects of Different Sampling Orders on Sludge Dewatering Performance

[0032] Carry out according to the sample amount of each material among the embodiment 1, difference is to be divided into following processing modes:

[0033] (1) Adding at the same time: Add all the materials to obtain the reaction system, and then put it in a six-way mixer for conditioning. Set it to stir quickly at 200 rpm for 2 minutes, and then stir slowly at 50 rpm for 30 minutes;

[0034] (2) Add Fe first 2+ / SPC: Fe 2+ / SPC After adding the remaining sludge first, put it in a six-way mixer for conditioning, set it to stir quickly at 200 rpm for 2 minutes, then add aluminum sludge and stir slowly at 50 rpm for 30 minutes;

[0035] (3) Add aluminum sludge first: After adding aluminum sludge to the remaining sludge, put it in a six-way mixer for conditioning, set it to stir at 200 rpm for 2 minutes, and then add Fe 2+ / SPC50 rpm and stir slowly for 30 min.

[0036] See image 3 :...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com