Automatic loading equipment for whole stack of materials in container

A technology for containers and materials, applied in the directions of loading/unloading, transportation and packaging, conveyors, etc., can solve the problem of ineffective use of container space, and achieve improved strength and stability, strong operational flexibility, and improved loading. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The following is attached Figure 1-12 The application is described in further detail.

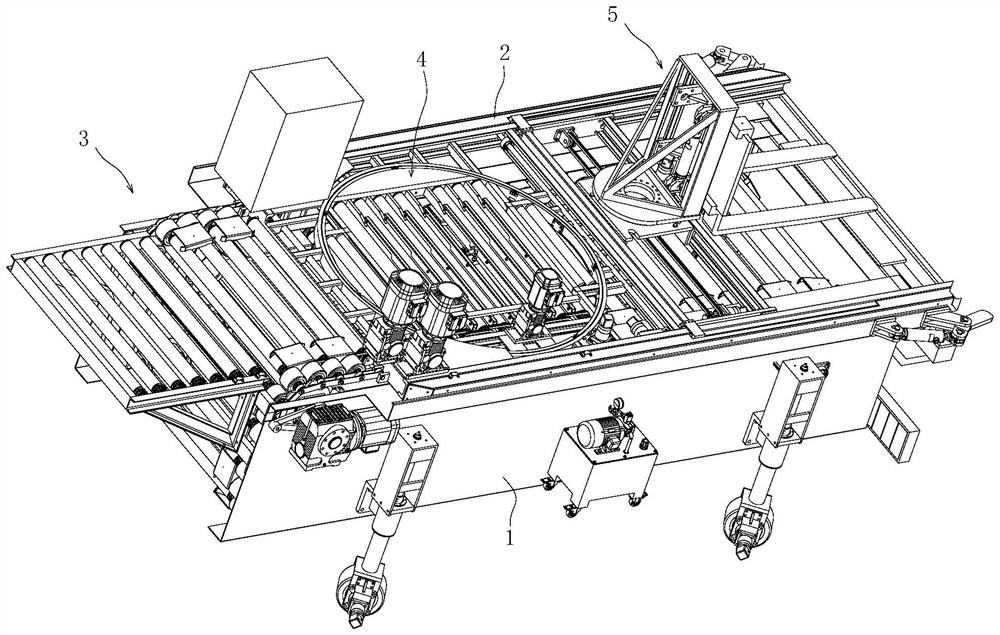

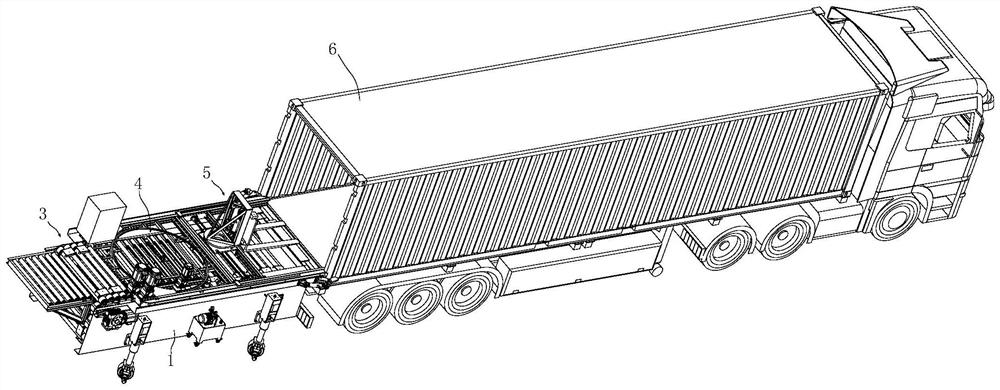

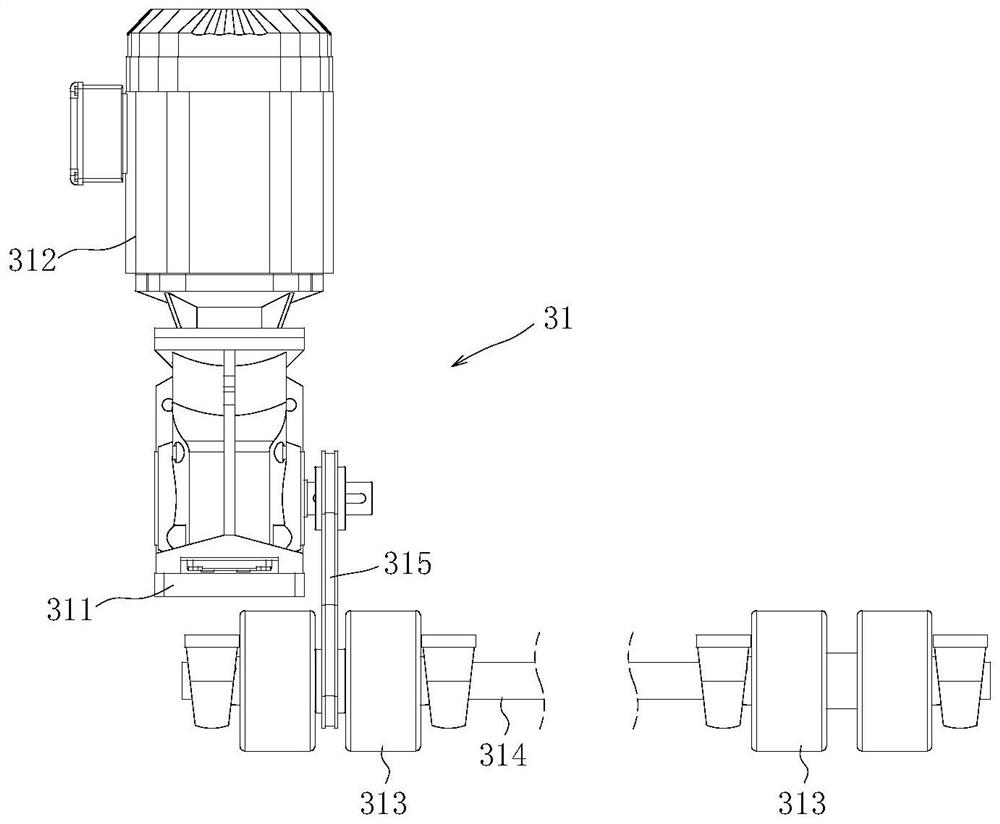

[0066] The embodiment of the present application discloses an automatic loading equipment for the whole stack of materials in the container. figure 1 , figure 2 , the equipment includes a frame 1, a sliding mounting frame 2, a driving guide feeding mechanism 3, a material angle adjusting mechanism 4 and a material palletizing mechanism 5.

[0067] Wherein, the driving guide feeding mechanism 3 is installed on one side of the sliding mounting frame 2, the material angle adjusting mechanism 4 and the material stacking mechanism 5 are installed on the sliding mounting frame 2, and the material stacking mechanism 5 is installed on one side of the material angle adjusting mechanism 4. On the other hand, from the perspective of the transfer route during the palletizing process, the cargo passes through the drive-guided feeding mechanism 3, the material angle adjustment mechanism 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com