Split acoustic release device and release mechanism for subsurface buoy

A release device, split-body sound technology, applied in the direction of measuring devices, buoys, motor vehicles, etc., can solve the problems of high requirements for the use and maintenance of acoustic releasers, hazards to circuit boards and batteries, and increased cost of pressure-resistant shells, etc. Lightweight, improved reliability, and short communication distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] refer to figure 1 , generally shows the structure of the submersible buoy according to the first embodiment of the present invention and the split acoustic release device for the submersible buoy, the split acoustic release device includes a controller 113, the underwater unit 101 of the underwater acoustic communication machine and the release part 119, the signal cable 103 is connected to the controller 113, the underwater unit 101 and the release part 119, the controller 113 establishes a data connection with the deck unit through the underwater unit 101, and after completing mutual identity authentication, after receiving the release of the deck unit In the case of a command from the gravity anchor 120, the command is converted into a relay control signal and sent to the release unit 119, and the release unit 119 executes the command to release the anchor chain 110, and the submerged buoy floats up and recovers under the buoyancy of the main buoyant ball 114.

[003...

Embodiment 2

[0048] refer to Figure 5 and Figure 6 , shows the release part 119 according to the second embodiment of the present invention, the release part 119 includes hexagon socket bolts 501, 509, cable holes 502, left bracket 503, right bracket 504, male connector 505, female connector 506, Second suction cup electromagnet 507, anchor chain hole 508, wedge-shaped block 510, wedge-shaped end 511, corrosion-resistant springs 512, 515, ejector rod 513, connection hole 514, coupling rod 516, ferromagnetic boss 517, signal cable 103.

[0049] It should be understood that, in the second embodiment, the upper connecting frame is protruded through the ejector rod 513 to engage with the lower connecting frame, therefore, the upper connecting frame is referred to as “male connecting piece 505” here and thereafter. , in the same way, the lower connecting frame is called "female connecting piece 506"; in addition, in this embodiment, the shape of the block is wedge-shaped, so the block is ca...

Embodiment 3

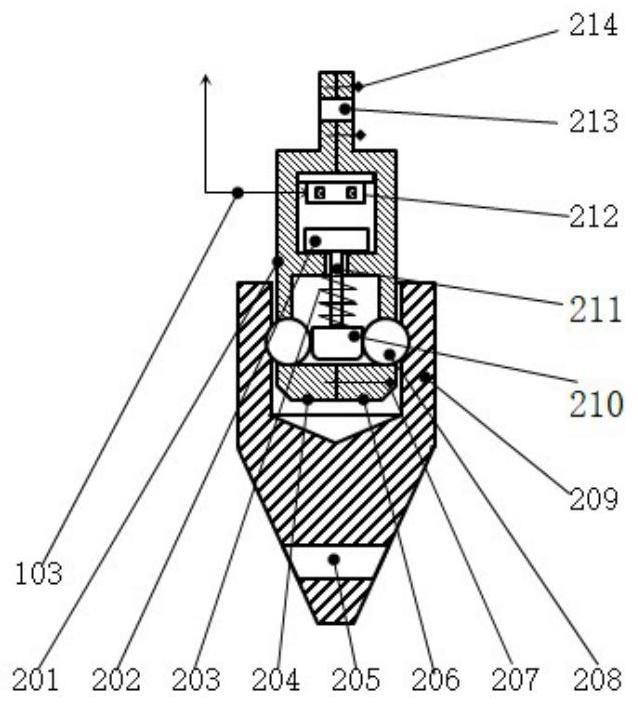

[0055] refer to Figure 7 , The split acoustic release device according to the present invention can also be used in a "parallel" manner to form the release mechanism 702 (here and subsequently, the release mechanism is also referred to as the parallel mechanism 702) to improve the reliability of submerged mark recovery. The parallel mechanism 702 connects the mooring cable 116 at the connection hole 703; the plastic steel ring 704 connects the lower connecting frame 209 and the steel chain 705, the steel chain 705 passes through the steel ring 706, and the steel ring 706 connects the anchor chain 110.

[0056] Preferably, the open steel ring is put into the lower connecting frame 209 and then welded to form a closed steel ring, and then plastic-steel ring 704 is made by overmolding.

[0057] The controller 113 sends a release command to one of the two split acoustic release devices, the first suction cup electromagnet 212 attracts the ferromagnetic disk 202, the stopper 210 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com