Clasp pipe fitting for connecting thin-wall metal pipe

A technology for metal pipes and pipe fittings, which is applied in the field of pipe fittings connecting thin-walled metal pipes, and can solve problems such as extrusion of thin-walled metal pipes in place, difficulty in controlling the quality of connection between thin-walled metal pipes and pipe fittings, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below, the present invention is described in further detail in conjunction with accompanying drawing and specific embodiment:

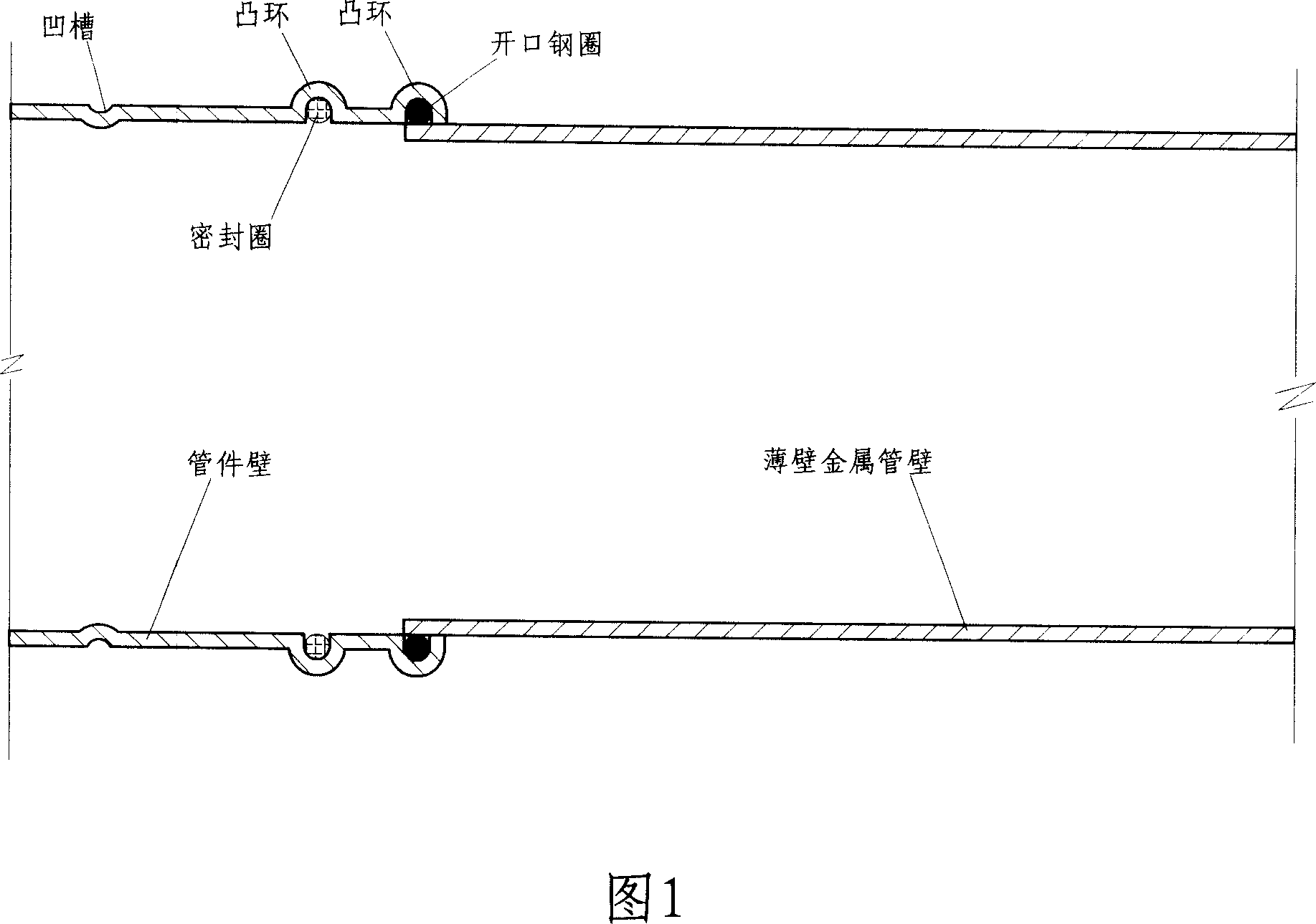

[0008] Fig. 1 shows: the shape of the pipe fitting mouth that is connected with the thin-walled metal pipe is a section of pipe with a special shape: the size of the inner diameter of the pipe is determined by just being able to insert the metal pipe to be connected. There are multiple protruding rings protruding outward on the pipe wall, and there are sealing rings or steel rings with openings in the protruding rings; further inside is a groove, and the distance from the groove to the fitting mouth can limit the length of the pipe inserted into the fitting .

[0009] Figure 2 shows the state when the thin-walled metal tube is inserted into the mouth of the fitting: after the metal tube is inserted into the fitting, the sealing ring and the opening steel ring are in the cavity between the outer wall of the metal tube and the inner wall of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com