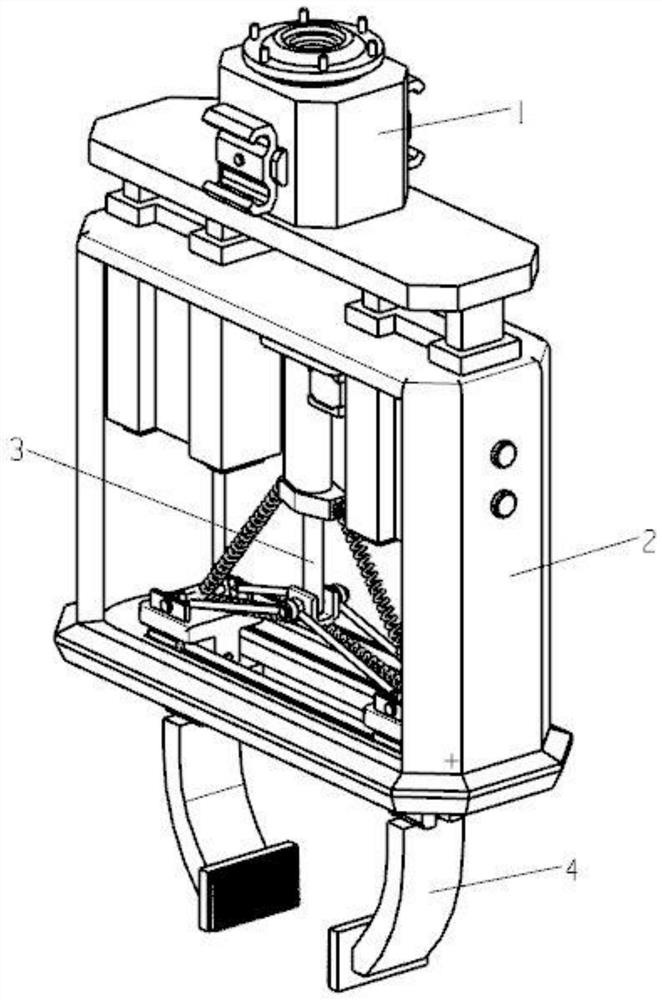

Shock absorption type robot gripper device with self-adjustment function

A robotic gripper and self-adjusting technology, applied in manipulators, manufacturing tools, chucks, etc., can solve the problems of unreliable clamping, low reliability, and no absorption, and achieve the effects of convenient operation, improved use range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described further.

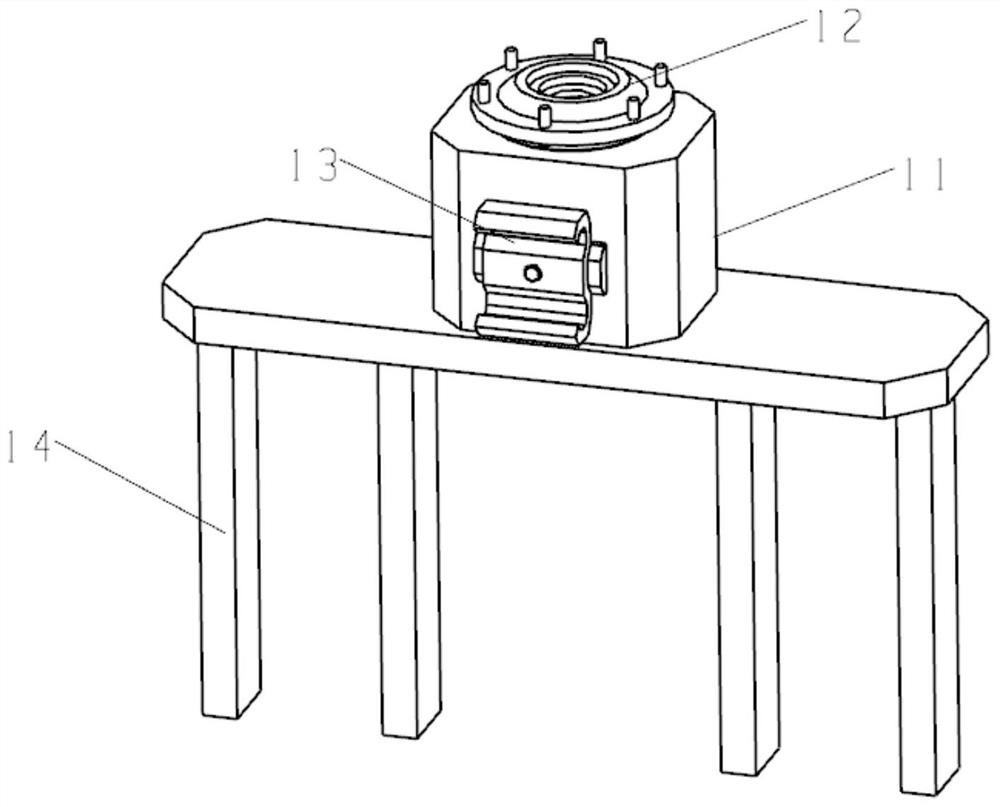

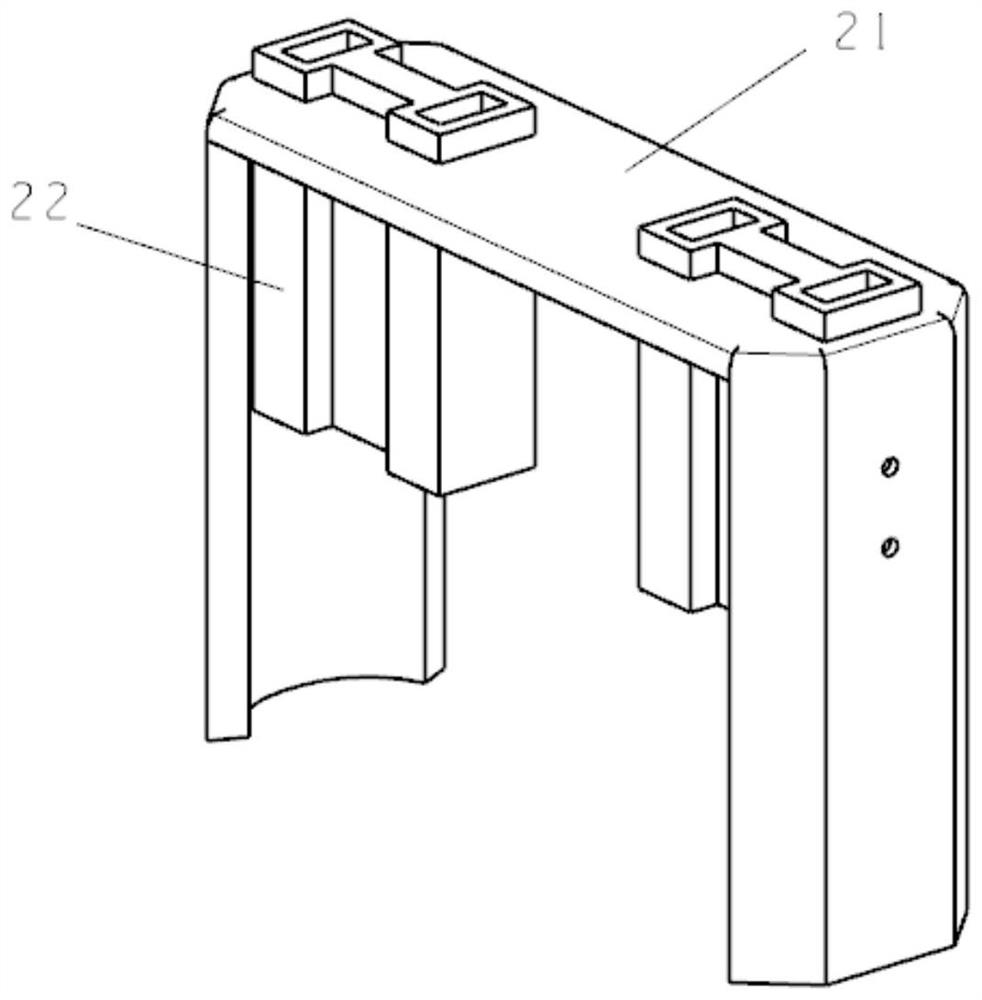

[0014] Referring to the accompanying drawings, a self-adjusting shock-absorbing robot gripper device includes: top connection device module 1; top frame 11; top suspension rail connection ring 12; side rail connection buckle 13; lifting guide rail 14; chassis module 2 ; Case skeleton 21; Lifting mechanism 22; Running device module 3; Motor 31; Electric push rod 32; Chassis chassis 33; Block 37; Second-stage spring 38; Grabbing device module 4; Grabbing pliers package lower connection block 41; Grabbing pliers 42; Wherein, top connecting device module 1 includes top hanging rail connecting ring 12, side track connecting buckle 13, lifting Guide rail 14; chassis module 2 includes chassis frame 21, lifting mechanism 22; operating device module 3 includes motor 31, electric push rod 32, chassis chassis 33, gripper package upper connection block 34, first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com