Motor assembly assembling equipment of parking actuator production line

A technology for motor components and assembly equipment, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of high labor intensity and low assembly efficiency, achieve automation and improve assembly efficiency, improve product qualification rate, reduce The effect of wrong loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

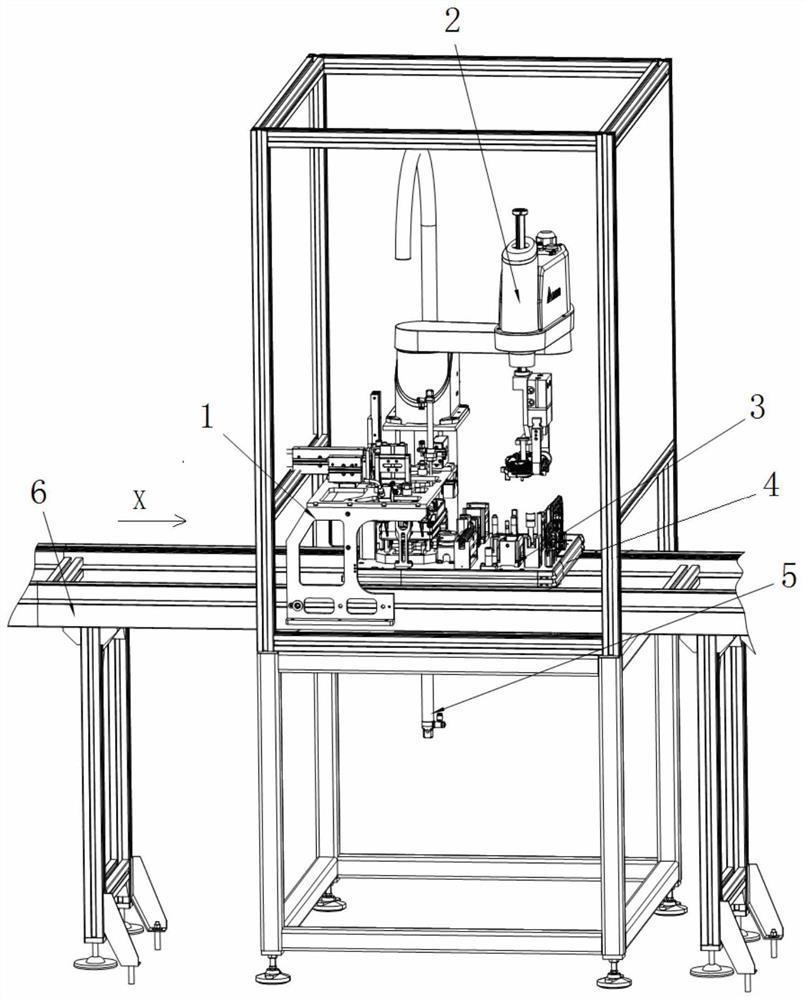

[0032] Such as Figure 1-10 As shown, the present invention includes an assembly mechanism 1, a rotation positioning mechanism 5, a motor assembly handling mechanism 2, a jacking positioning mechanism 3 and a pallet 4, wherein the base to be assembled is arranged on the pallet 4, and the pallet 4 passes through a transmission line 6 Drive to move to the assembly station and realize the positioning through the jacking positioning mechanism 3. The assembly mechanism 1, the rotating positioning mechanism 5, and the motor component handling mechanism 2 located at the assembly station work together to complete the assembly operation.

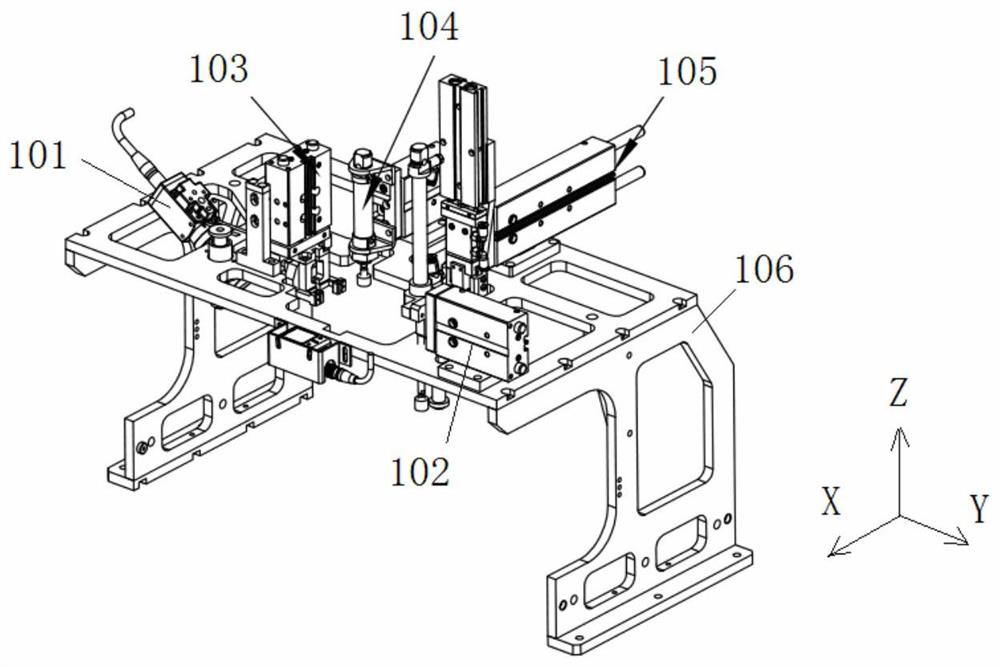

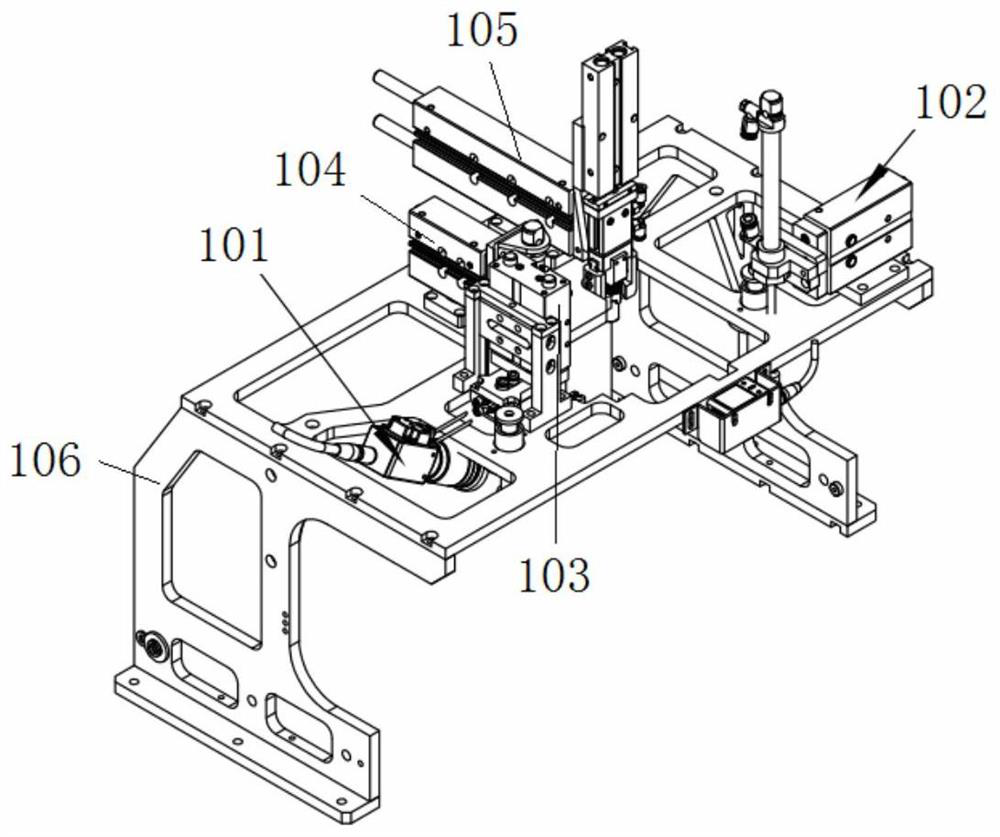

[0033] Such as Figure 2-6 As shown, the assembly mechanism 1 includes a PCB board positioning component 103, a column gear moving component 105, a first press-fit component 102, a second press-fit component 104 and a mounting brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com