Bio-organic fertilizer granulation device

A bio-organic fertilizer and granulation device technology, which is applied in dryers, grain processing, drying gas layout, etc., can solve the problems of uneven spraying, slow granulation speed, and high labor consumption, so as to reduce production costs and speed up Granulation process, the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solutions and advantages of the application clearer, the implementation of the application will be described in detail below with reference to the accompanying drawings, but the embodiments described in the application are some of the embodiments of the application, not all of them.

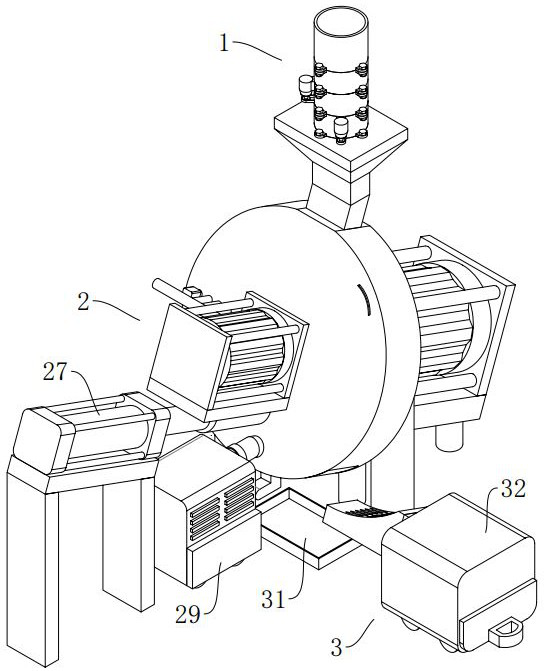

[0036] Such as Figure 1-Figure 12 A bio-organic fertilizer granulation device shown includes a crushing unit 1 , a granulation unit 2 , and a receiving unit 3 .

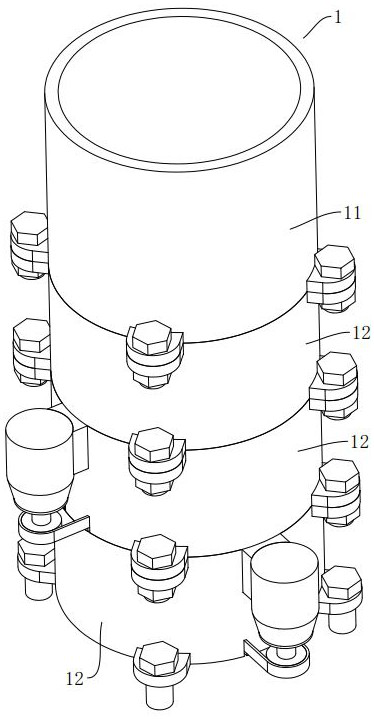

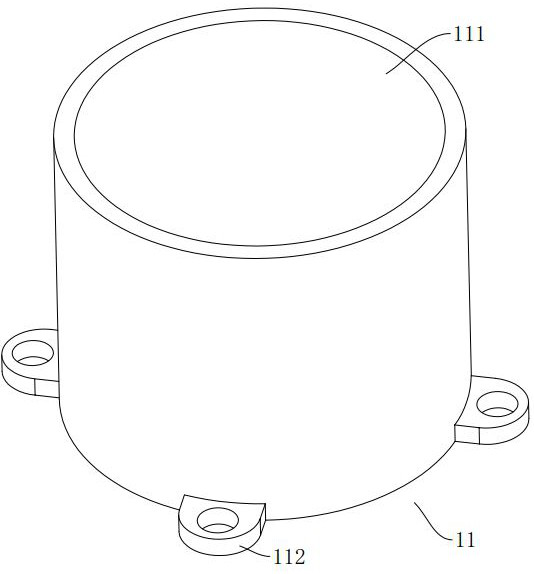

[0037] Pulverizing unit 1 is used for pulverizing bulk raw material, and pulverizing unit 1 comprises discharging mechanism 11 and several layers of pulverizing mechanisms 12 that are arranged at the lower end of discharging mechanism 11, and discharging mechanism 11 comprises discharging pipe 111, and its lower end peripheral side is provided with four A first screw hole 112, the crushing mechanism 12 includes a crushing tube 121, four second screw holes 122 are respectively provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com