Method and device for separating gaseous hydrocarbon materials

A technology for gaseous hydrocarbons and gaseous materials, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as underutilization of ethane resources, reduce equipment investment, reduce energy consumption, and reduce tower kettles The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

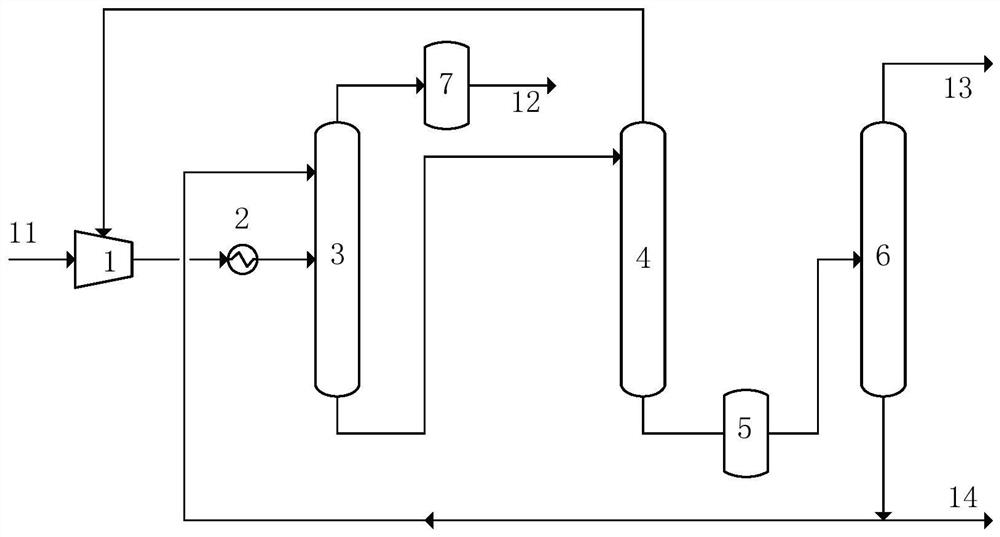

[0043] According to a particularly preferred embodiment of the present invention, the method comprises the following steps:

[0044] (1) compressing the gaseous hydrocarbon material to increase the pressure to 3-4MPa, and then cooling to 10-20°C to obtain compressed and cooled gaseous hydrocarbon material;

[0045] (2) Liquid absorbent (such as benzene) is entered in the tower from the tower top of absorption tower, and the gaseous hydrocarbon material after the compression cooling that obtains through step (1) enters from the tower bottom of absorption tower, gaseous hydrocarbon material and benzene Contact (the theoretical plate number of the absorption tower is 15-25, the operating pressure is 2-3.5MPa, and the tower top temperature is 30-40°C), so that the components above carbon three in the gaseous hydrocarbon material are absorbed by benzene to obtain carbon-containing More than three rich solvent materials, the top of the tower is a light component containing carbon tw...

Embodiment 1

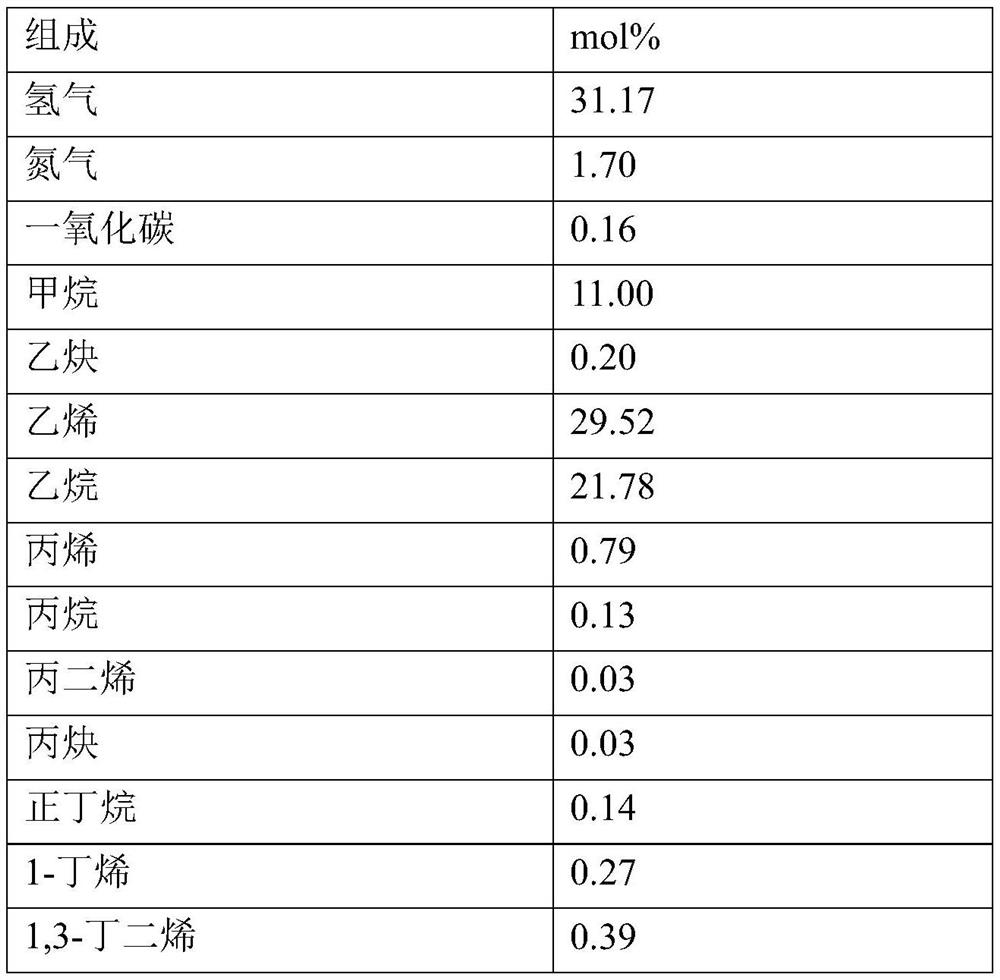

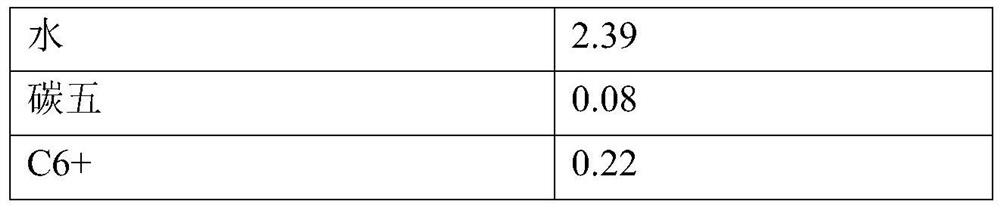

[0063] (1) The gaseous hydrocarbon material 11 is compressed in five stages by the compressor 1, so that the pressure of the gaseous hydrocarbon material 11 is increased to 3.5MPa, and then cooled to 15° C. by the cooler 2 to obtain compressed and cooled gaseous hydrocarbons materials;

[0064] (2) The theoretical plate number of absorption tower 3 is 20, operating pressure is 3.1MPa, tower top temperature 35 ℃; With benzene as liquid absorbent, liquid absorbent is entered in the tower from the tower top of absorption tower 3, through step ( 1) The obtained compressed and cooled gaseous hydrocarbon material enters from the bottom of the absorption tower 3, and the gaseous hydrocarbon material is contacted with benzene so that the components above carbon three in the gaseous hydrocarbon material are absorbed by benzene to obtain carbon three The above solvent-rich material, the tower top is the light component containing carbon two or less components and entrained with a small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com