Modified pearl powder, preparation method thereof and cosmetic containing modified pearl powder

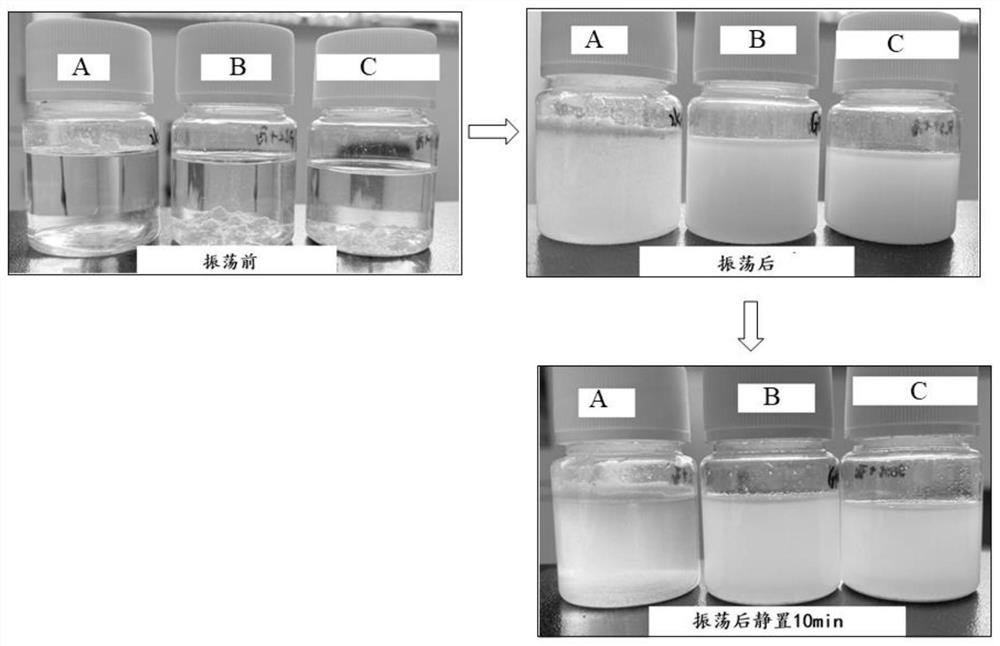

A pearl powder and modified technology, used in cosmetics, cosmetic preparations, cosmetic preparations, etc., can solve the problems of reduced cosmetic stability, destruction of cosmetic emulsion systems and suspension systems, and inability to degrade silica, achieving excellent Skin affinity, excellent moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of modified pearl powder provided by the invention may further comprise the steps:

[0028] S1, mix pearl powder with water to obtain a slurry, mix lauroyl lysine, alkaline substances and water to obtain a first solution with a pH greater than or equal to 13.25, and mix the first solution with the slurry to obtain a pH greater than or equal to equal to the first suspension of 11.5;

[0029] S2, under the condition of stirring, add the acidic solution to the first suspension to obtain the second suspension, wherein the mass fraction of the acidic solution is 5%-15%, and the adding speed of the acidic solution is gradually reduced, with 500mL For the first suspension, the initial addition rate of the acidic solution is 0.02mL / s-0.2mL / s; and

[0030] S3, aging the second suspension to obtain modified pearl powder.

[0031] In step S1, the pH of the first solution is greater than or equal to 13.25, and the pH of the first suspension is greater than ...

Embodiment 1

[0058] Mix 100g of pearl powder with a particle size of 3 μm and 400g of deionized water, and stir evenly at room temperature to obtain a slurry; after mixing 24g of deionized water and 4.4g of a 31% sodium hydroxide aqueous solution with a mass fraction of 31%, add 3g Lauroyl lysine, after dissolving completely, obtains the first solution that pH is 13.27; The first solution is added in the slurry, stirs 30min, obtains the first suspension that pH is 12.63; In terms of 100g pearl powder, lauroyl lysine The quality of acid and the particle size of pearl powder satisfy the following relationship: 1g: 1μm.

[0059] Under the stirring condition of 310r / min, slowly add hydrochloric acid with a mass fraction of 12% into the first suspension, and the addition speed gradually slows down. Based on 500ml of the first suspension, the initial addition speed of the acidic solution is 0.06mL / s, the second suspension with a pH of 6.32 was obtained.

[0060] Aging the second suspension for...

Embodiment 2

[0062] Mix 100g of pearl powder with a particle size of 7.5 μm and 400g of deionized water, stir evenly at room temperature to obtain a slurry; mix 24g of deionized water with 4.4g of 31% sodium hydroxide aqueous solution, and then add 3g Lauroyl lysine obtains the first solution that pH is 13.25; The first solution is added in the slurry, stirs 30min, obtains the first suspension that pH is 12.58; Based on 100g pearl powder, the quality of lauroyl lysine The particle size of pearl powder satisfies the following relationship: 0.4g: 1μm.

[0063] Under the stirring condition of 316r / min, hydrochloric acid with a mass fraction of 12% was slowly added to the first suspension to obtain a second suspension with a pH of 6.24.

[0064] Aging the second suspension for 30 minutes and then filtering, collecting the filter cake, washing the filter cake with water until the conductivity of the effluent is less than or equal to 100 μs / cm, drying the washed filter cake, and mechanically pul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com