Production equipment applied to environment-friendly nickel pig iron production

A production equipment, nickel pig iron technology, applied in the field of production equipment for the production of environmentally friendly nickel pig iron, can solve the problems of inability to collect wind and dust, incapable of secondary crushing of raw materials, etc., to achieve the effect of improving the crushing effect and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

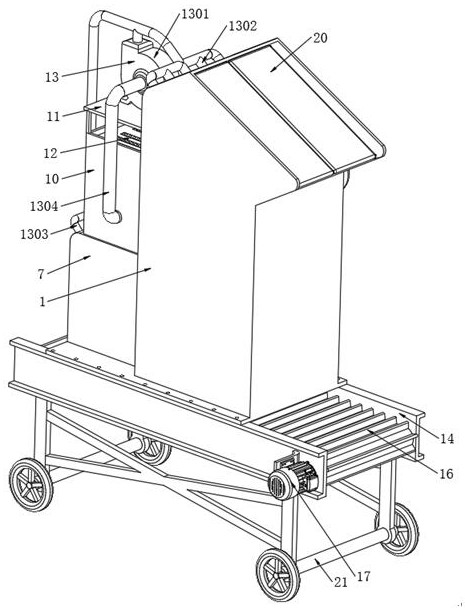

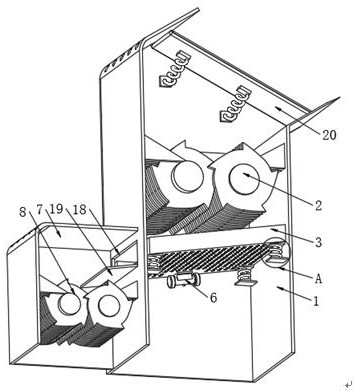

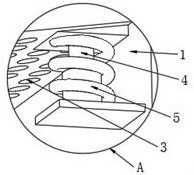

[0029] Such as Figure 1-Figure 5 As shown, a kind of production equipment applied to the production of environmentally friendly nickel pig iron proposed by an embodiment of the present invention includes a crushing box 1, and two first crushing rollers 2 are connected in the crushing box 1 through bearing rotation, and the first crushing roller 2 A screen frame 3 is arranged below, four telescopic sleeves 4 are symmetrically fixed on the bottom of the screen frame 3, the surface of the telescopic sleeves 4 is provided with first springs 5, and the tops of the first springs 5 are connected to the bottom of the screen frame 3. Fixed, the bottom of the first spring 5 is fixed in the crushing box 1, the bottom of the screen frame 3 is fixed with a vibrating motor 6, the side wall of the crushing box 1 is fixed with a housing 7, and the housing 7 is connected with a Two second crushing rollers 8, the crushing box 1 is provided with a driving mechanism 9 for driving the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com