Retroreflective sheet provided with pattern for improving retroreflection coefficient

A retro-reflection and patterning technology, applied in optical components, optics, instruments, etc., can solve the problems of difficulty in manufacturing, difficult to meet the standard of viewing angle of light, high retro-reflection coefficient, etc., to improve the retro-reflection coefficient, improve visibility, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

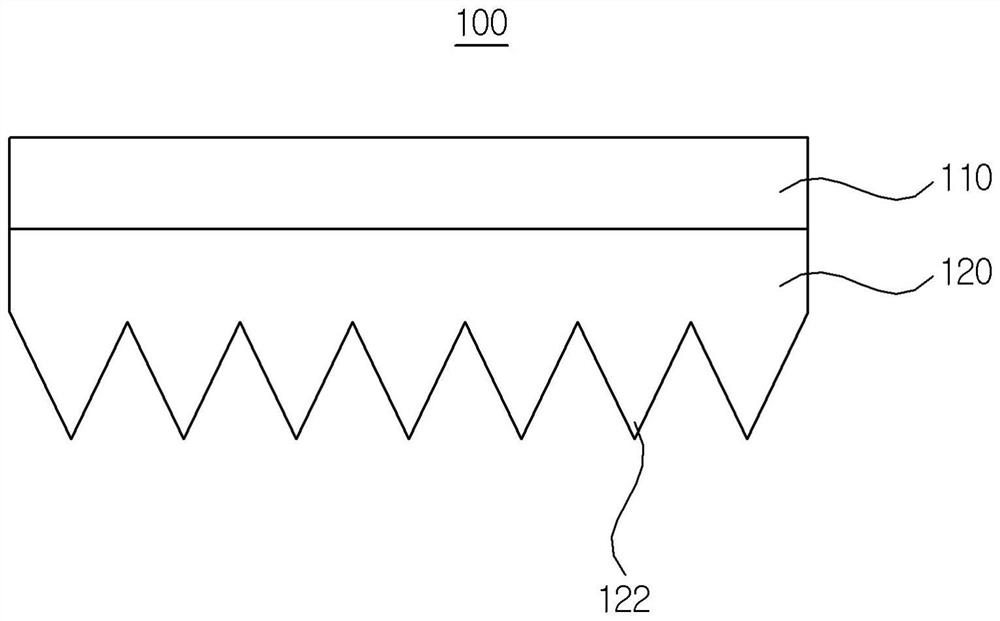

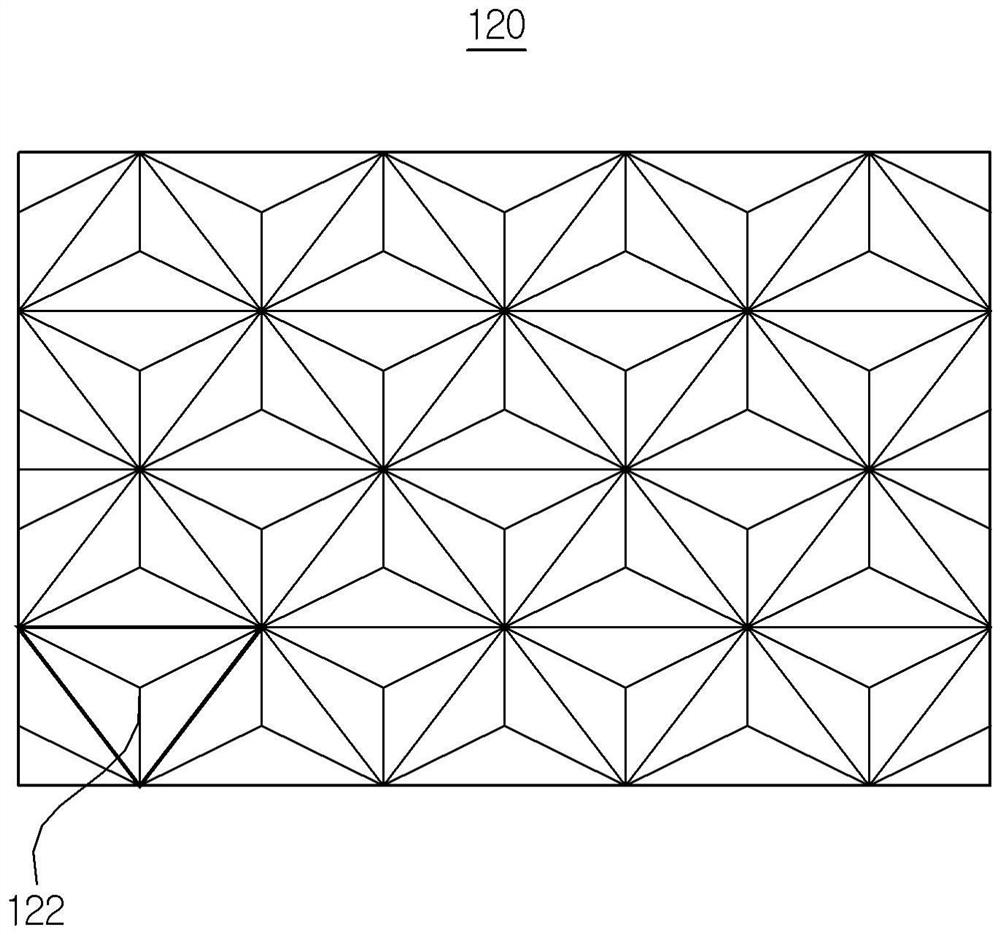

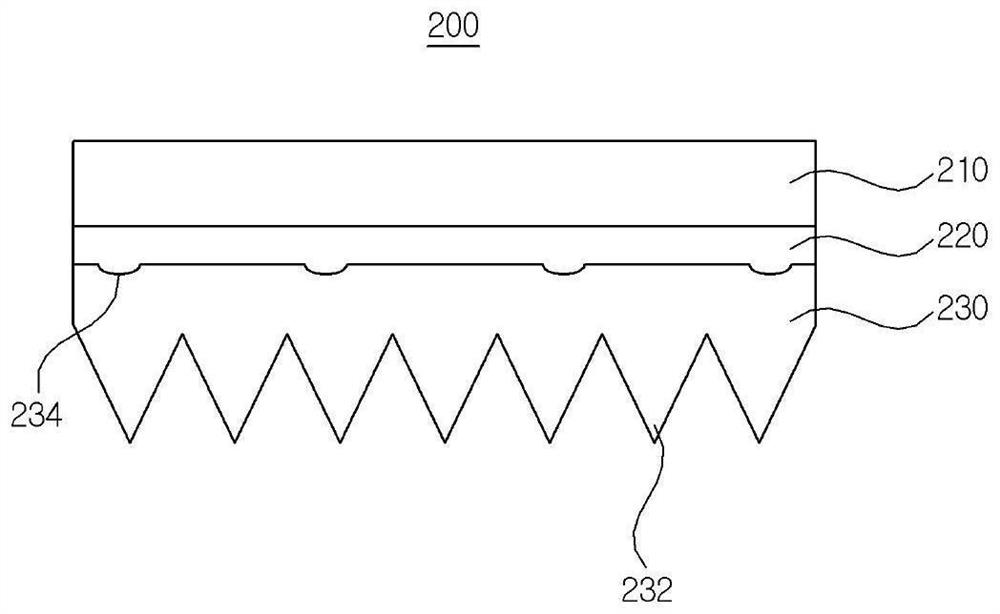

[0027] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. When describing the present invention, if it is judged that the detailed description of related known structures or functions will make the gist of the present invention unclear, the detailed description will be omitted. Preferred embodiments of the present invention will be described below, however, the technical spirit of the present invention will not be limited or restricted by the preferred embodiments, and can be modified and implemented in various forms by those skilled in the art. Hereinafter, the retroreflective sheeting provided with the pattern for increasing the coefficient of retroreflection proposed by the present invention will be described in detail with reference to the accompanying drawings.

[0028] The term "layer" used in the present invention includes the meaning of film (film) type and / or sheet (sheet) type, and "pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com