High-power-density permanent magnet synchronous motor and flywheel integrated device

A technology of permanent magnet synchronous motor and high power density, which is applied in the direction of electromechanical devices, electrical components, electric components, etc. It can solve the problems of radial magnetic field motor shaft length and poor shaft stability, and achieve low self-dissipation rate, The effect of low torque ripple and avoiding electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

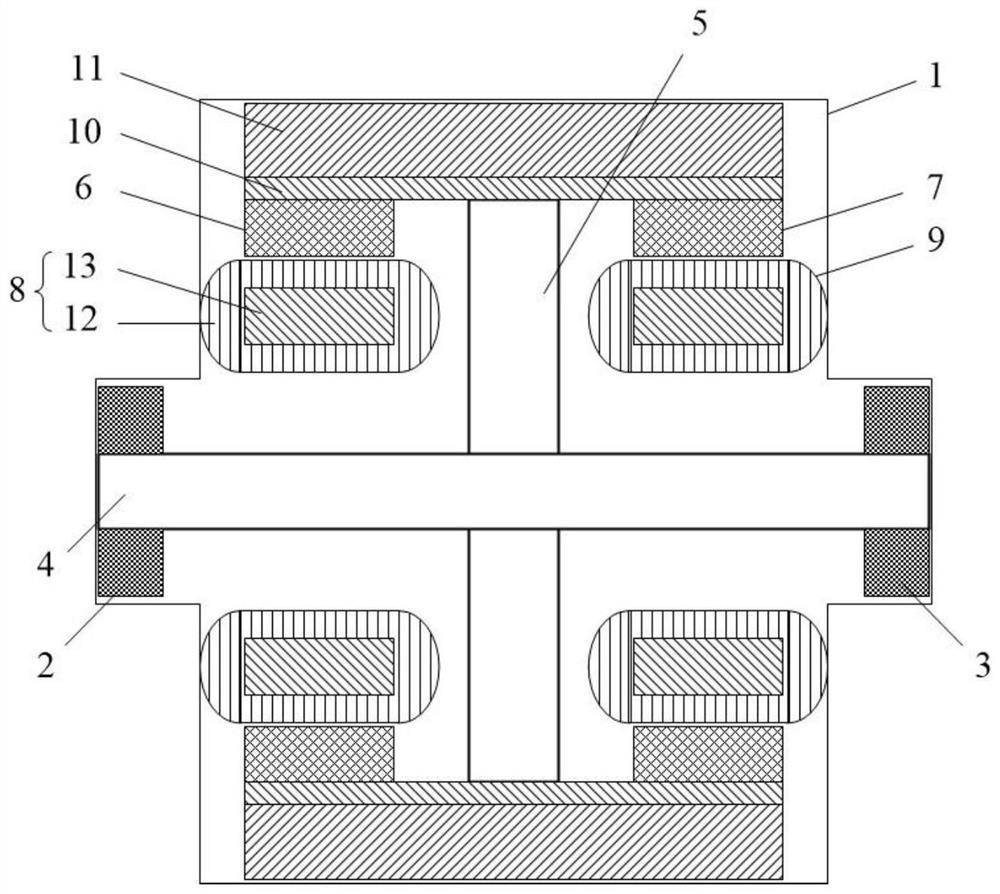

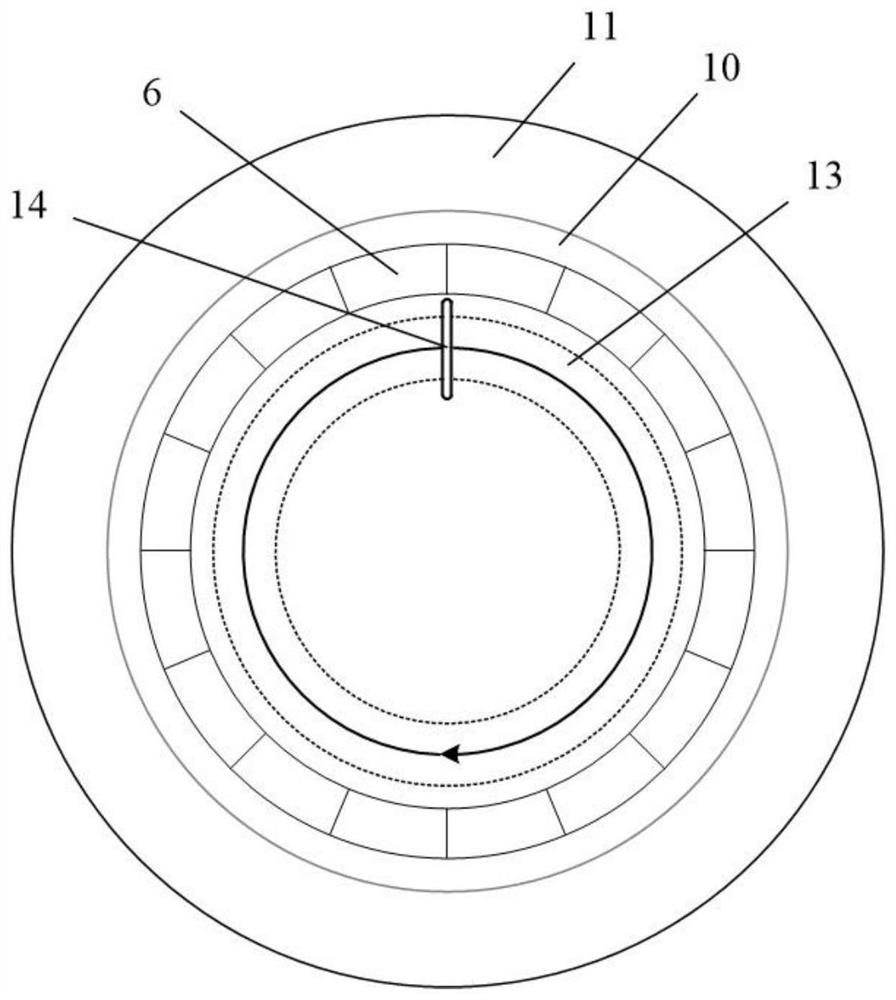

[0032] The disclosed content of the present invention is as follows figure 1 The structural schematic diagram of a high power density permanent magnet synchronous motor and flywheel integration device shown and the figure 2 A schematic diagram of the magnetic circuit of a permanent magnet synchronous motor with a high power density permanent magnet synchronous motor and flywheel integrated device when a winding short circuit fault occurs.

[0033] An embodiment of the present invention provides a high power density permanent magnet synchronous motor and flywheel integrated device, including a vacuum cover (1), a first magnetic bearing (2), a second magnetic bearing (3), a rotating shaft (4), and a rotor disk (5), first rotor module (6), second rotor module (7), first stator module (8), second stator module (9), rotor yoke (10) and flywheel (11).

[0034] Furthermore, as a specific implementation of a high power density permanent magnet synchronous motor and flywheel integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com