Decorative assembled plate based on wheat straw recycling and use method

A technology of wheat straw and boards, which is applied in covering/lining, construction, building construction, etc., can solve the problems of shortened life of boards, easy moisture, inconvenient splicing and installation, etc., to ensure stability, reduce heat loss, and improve sealing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

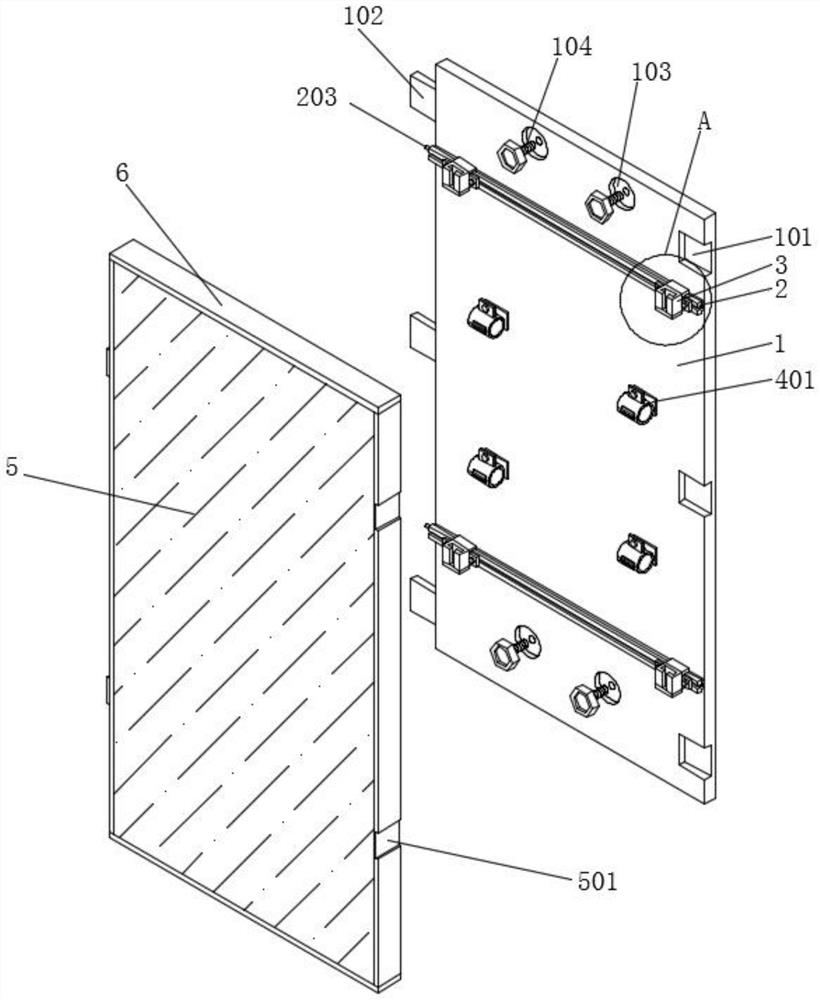

[0041] The first embodiment includes a wall-mounted board 1 and a support groove 3. One side of the wall-mounted board 1 is provided with three sets of fitting grooves 101 arranged up and down. The inserting pieces 102 are arranged, and the three sets of inserting pieces 102 are in one-to-one correspondence with the three sets of inserting grooves 101. The front side of the wall panel 1 is provided with two sets of symmetrically arranged limit grooves 103. The limit grooves A fixing screw 104 is installed through the inner side of the 103, the fixing screw 104 is placed on the inner side of the limit slot 103, and the fixing screw 104 passes through the inner side of the limit slot 103, and the wall panel 1 is fixed on the wall to ensure that the wall is attached to the wall. The stability of the board 1 avoids the movement of the wallboard 1 during the installation process. The worker installs several groups of the wallboard 1 as needed, and the worker inserts the inserts 102 ...

Embodiment 2

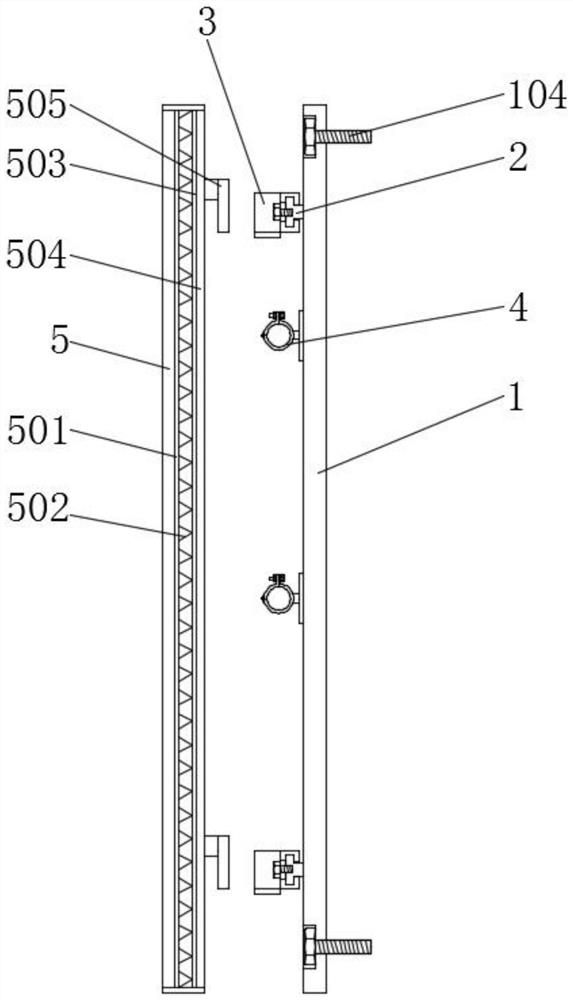

[0043] The second embodiment includes a wall-mounted board 1 and a support groove 3. The front of the wall-mounted board 1 is installed with two sets of support slideways 2 arranged up and down. The front end of the support slideway 2 is provided with a slide groove 201. One end of the support slideway 2 is provided with a positioning socket 202, and the other end of the support slideway 2 is installed with a positioning plug-in 203. The positioning plug-in 203 on the upper part is docked, which is convenient for workers to assemble the device and ensures the tightness of the connection of the support slideways 2, so that the two sets of support slideways 2 on the slide grooves 201 are precisely butted, and the positioning plug-in 203 corresponds to the positioning jack 202. Two sets of sliding blocks 301 are movably installed on the outer sides of the two sets of the support slideways 2 , the support grooves 3 are installed in front of the sliding blocks 301 , and two sets of ...

Embodiment 3

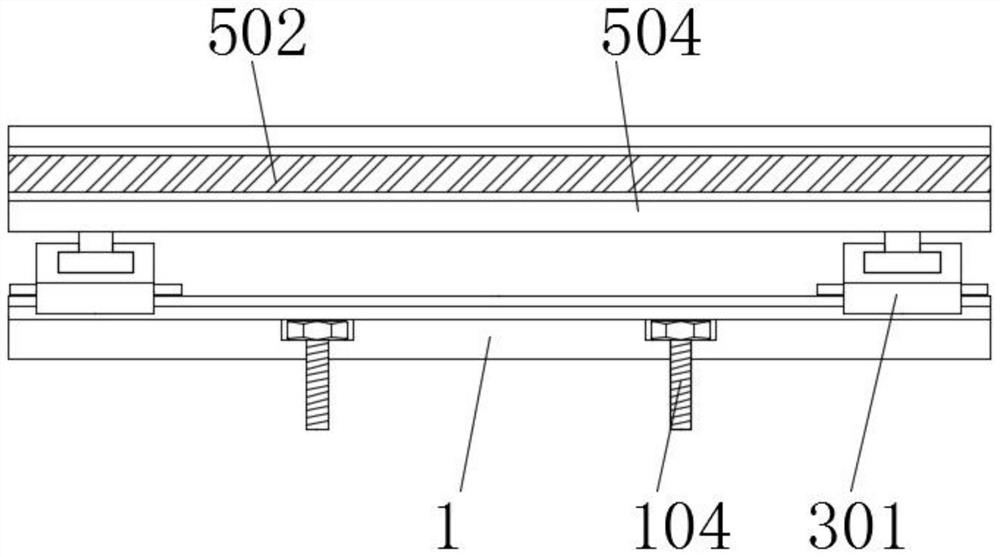

[0045] The third embodiment includes a wall panel 1 and a support groove 3. The support groove 3 is fitted with a support pendant 505, a support plate 504 is installed in front of the support pendant 505, and a front surface of the support plate 504 is installed The first adhesion layer 503, the wheat straw composite insulation board 502 is installed on the front of the first adhesion layer 503, and the second adhesion layer 501 is installed on the front of the wheat straw composite insulation board 502, and the second adhesion layer 501 is A decorative panel 5 is installed on the front, and the first adhesive layer 503, the wheat straw composite insulation board 502, the second adhesive layer 501 and the decorative panel 5 are all installed on the inner side of the closing plate 6, and the outer side of the support plate 504 is installed with a closing plate 6. One side of the closing plate 6 is provided with two sets of upper and lower clamping grooves 601, and the other side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com