Preparation method of cobalt-nickel alloy particle hydrophilic carbon cloth composite material with corn cob-like heterostructure

A heterogeneous structure, cobalt-nickel alloy technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problem of inability to meet the requirements of high-efficiency wave-absorbing materials, the mismatch of nickel-cobalt alloy electromagnetic parameters, and the inability to meet Lightweight requirements and other issues, to achieve the effect of easy control of wave absorption performance, excellent electromagnetic wave absorption performance, and thin matching thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

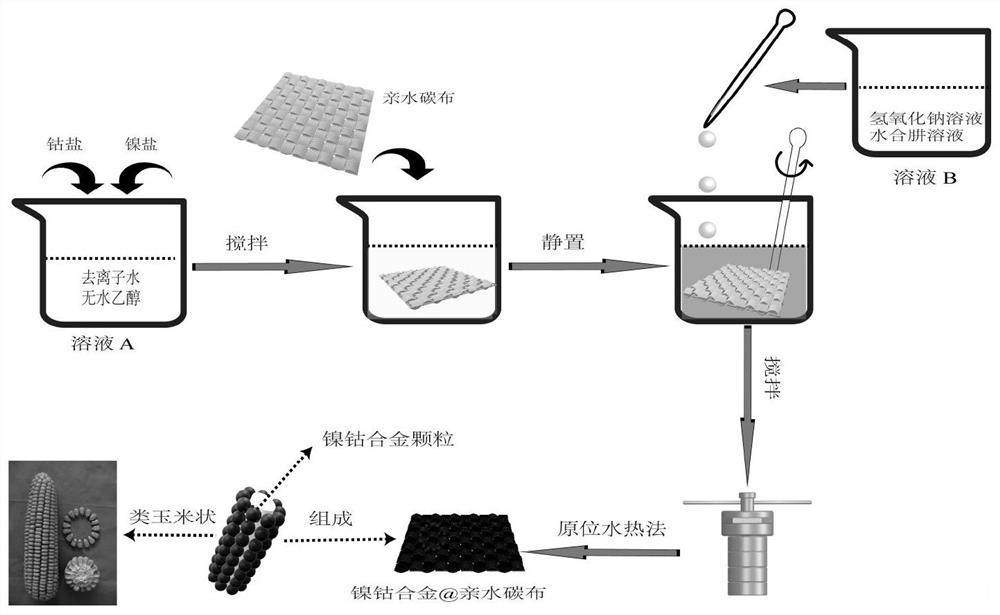

[0044] A method for preparing a cobalt-nickel alloy particle hydrophilic carbon cloth composite material with a corn cob heterostructure, the preparation method comprising the following steps:

[0045] Step 1: Mix 7.5mL deionized water and 7.5mL absolute ethanol to obtain a mixed solution.

[0046]Step 2: adding nickel salt (one or more of nickel nitrate, nickel chloride, nickel sulfate) and cobalt salt (one or more of cobalt nitrate, cobalt chloride, cobalt sulfate) to the mixture Magnetic stirring was carried out in the solution for 30-90 min to obtain solution A.

[0047] Step 3: adding the hydrophilic carbon cloth to the solution A and standing for 6-24 hours to obtain a nickel-cobalt salt solution containing the hydrophilic carbon cloth;

[0048] Step 4: Stir 5mL of sodium hydroxide solution and 5mL of hydrazine hydrate for 30-120min to obtain solution B;

[0049] Step 5: While adding the solution B dropwise to the nickel-cobalt salt solution containing hydrophilic carb...

Embodiment 1

[0056] This implementation case shows a preparation method of a cobalt-nickel alloy particle hydrophilic carbon cloth composite material with a corn cob heterogeneous structure according to the following steps:

[0057] Step 1: Mix 7.5mL deionized water and 7.5mL absolute ethanol to obtain a mixed solution.

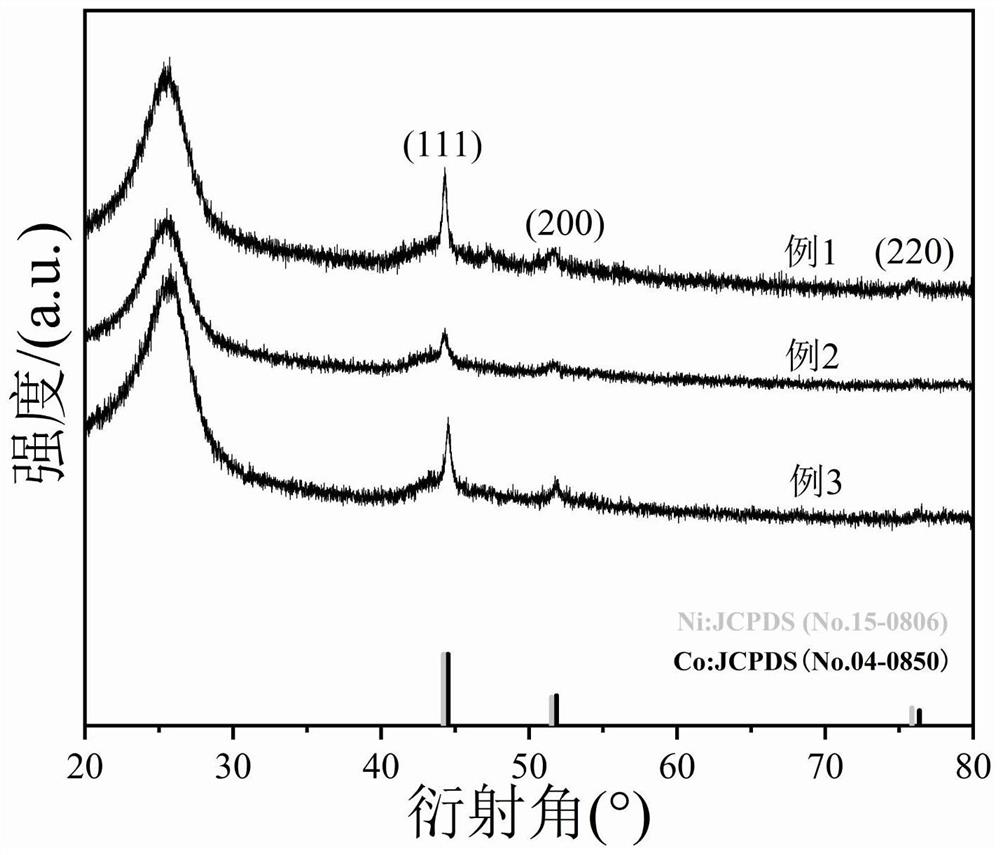

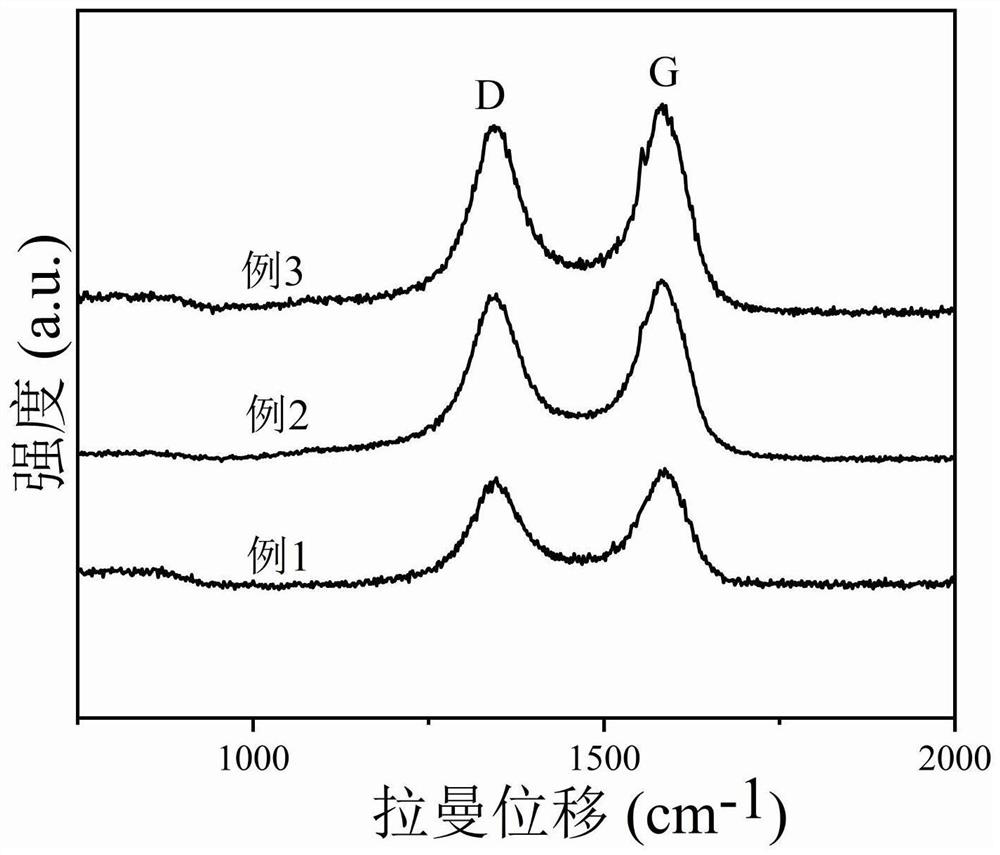

[0058] Step 2: Add 1.5 mmol of nickel chloride and 1.5 mmol of cobalt chloride into the mixed solution and perform mechanical stirring for 30 min to obtain solution A.

[0059] Step 3: adding the hydrophilic carbon cloth into the solution A and standing still for 6 hours to obtain a nickel-cobalt salt solution containing the hydrophilic carbon cloth;

[0060] Step 4: 5mL of 1mol / L sodium hydroxide solution and 5mL of 50wt% hydrazine hydrate were magnetically stirred for 30min to obtain solution B;

[0061] Step 5: While adding the solution B dropwise to the nickel-cobalt salt solution containing hydrophilic carbon cloth, stirring the nickel-cobalt salt solution containin...

Embodiment 2

[0065] This implementation case shows a preparation method of a cobalt-nickel alloy particle hydrophilic carbon cloth composite material with a corn cob heterogeneous structure according to the following steps:

[0066] Step 1: Mix 7.5mL deionized water and 7.5mL absolute ethanol to obtain a mixed solution.

[0067] Step 2: Add 1.8 mmol nickel nitrate and 1.2 mmol cobalt nitrate to the mixed solution and perform magnetic stirring for 90 min to obtain solution A.

[0068] Step 3: adding the hydrophilic carbon cloth into the solution A and standing still for 18 hours to obtain a nickel-cobalt salt solution containing the hydrophilic carbon cloth;

[0069] Step 4: 5mL of 3mol / L sodium hydroxide solution and 5mL of 50wt% hydrazine hydrate were magnetically stirred for 90min to obtain solution B;

[0070] Step 5: While adding the solution B dropwise to the nickel-cobalt salt solution containing hydrophilic carbon cloth, stirring the nickel-cobalt salt solution containing hydrophil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com