Dosing device

A technology of dosing device and silo, which is applied in neutralizing water/sewage treatment, process efficiency improvement, metallurgical wastewater treatment, etc., and can solve problems such as failure of dosing device, inaccurate control of chemical concentration, high failure rate of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

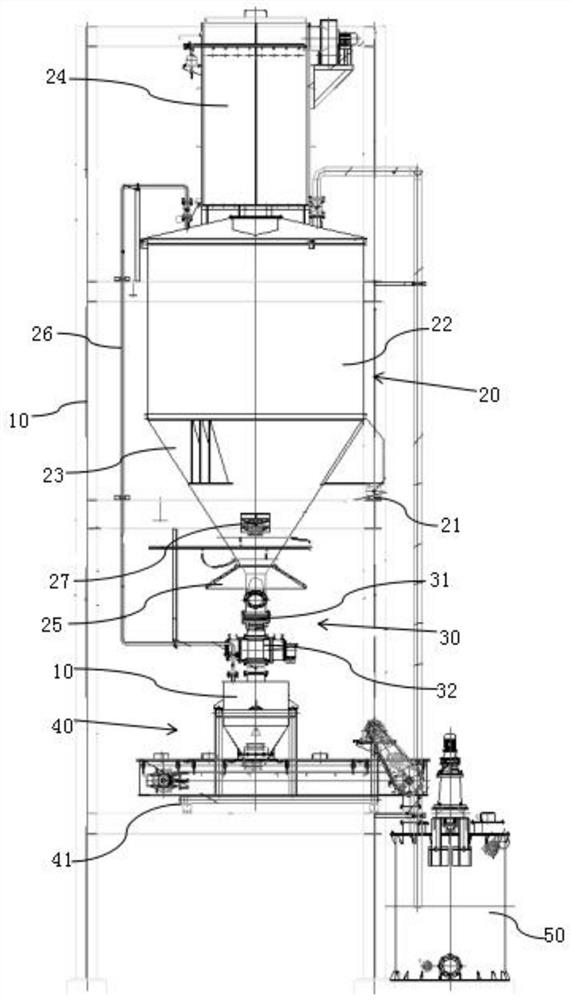

[0010] Such as figure 1 As shown, a dosing device is provided with a feed bin 20 on the frame 10, a discharge valve unit 30 is provided at the outlet of the feed bin 20, and a buried scraper conveyor 40 is provided below the discharge valve unit 30. The discharge end of the plate conveyor 40 is connected with the mixing barrel 50, and the bin 20 and the buried scraper conveyor 40 are respectively provided with a bin weighing unit 21 and a conveying weighing unit 41, and the bin weighing unit 21 monitors the material in real time. The weight of the medicament in the bin and transmit the signal to the control unit, the control unit controls feeding to the silo 20 or stops the feeding, and the conveying weighing unit 41 collects the amount of medicine on the buried scraper conveyor 40 and transmits the signal to the control unit unit, the control unit controls the rotational speed of the servo motor of the buried scraper conveyor 40 . The medicine is transported to the silo 20 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com