Method for improving dark fermentation hydrogen production performance by using ferroferric oxide/reduced graphene oxide nano composite material

A nano-composite material and technology of ferroferric oxide, applied in iron oxide/iron hydroxide, chemical instruments and methods, fermentation, etc., can solve the problem of low hydrogen production and achieve the effect of sludge reduction treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

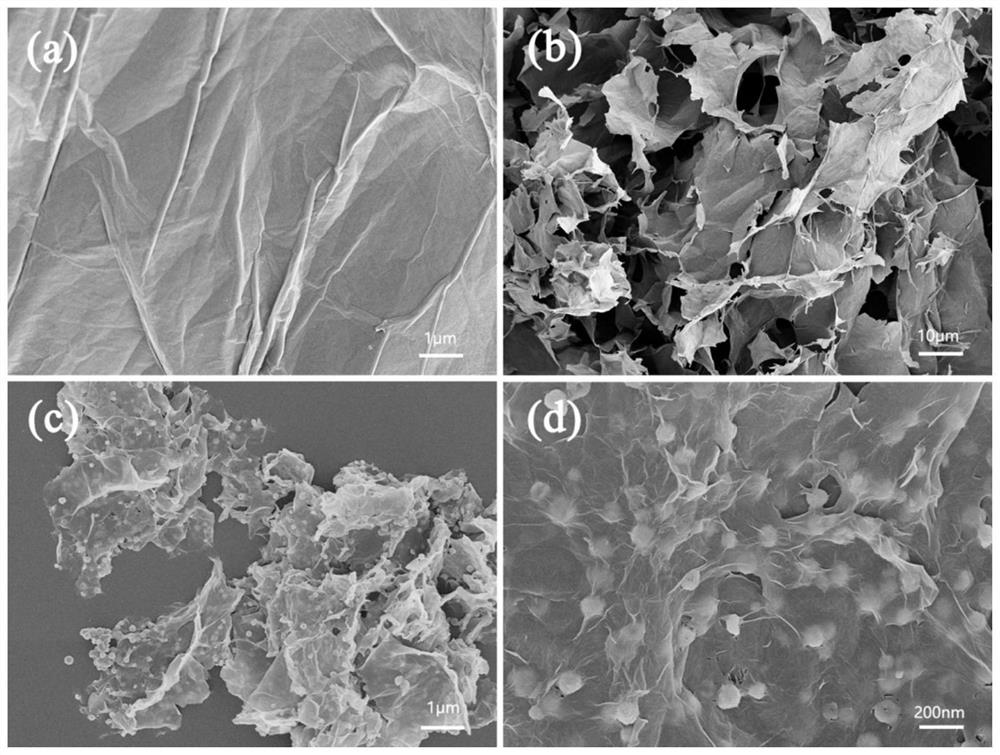

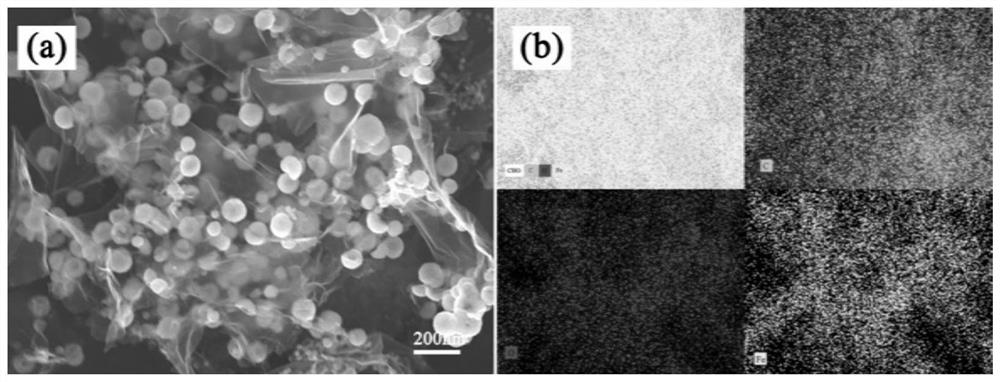

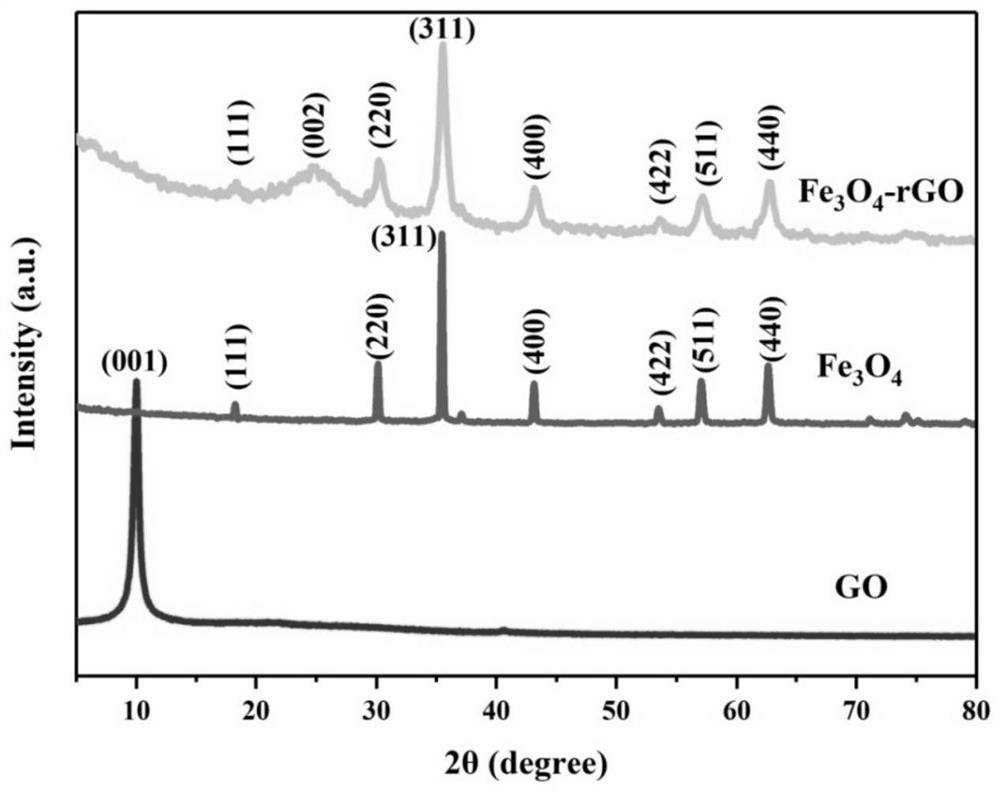

[0058] The preparation method of ferroferric oxide / reduced graphene oxide nanocomposite:

[0059] Step (1), according to the improved Hummers method to prepare GO with flake graphite as raw material.

[0060] a. Dissolve 5g flake graphite and 2.5g sodium nitrate in 120mL of H 2 SO 4 In, slowly add 15g of potassium permanganate and stir rapidly in ice-water bath for 2h.

[0061] b. Put the flask containing the mixed solution in an oil bath at 35°C for 2 hours, take out the flask and put it in an ice-water bath, and add 200 mL of deionized water.

[0062] c. Put the flask in an oil bath at 98° C. for 1.5 h. After the reaction, pour the mixture in the flask into a 1000 mL beaker, and add deionized water until the volume reaches 1000 mL.

[0063] d. Slowly add 20mL of 30wt% H 2 o 2 , the solution turned bright yellow, and sealed for 12h.

[0064] e. The supernatant was discarded, ultrasonically stripped for 1 h, washed with HCl (0.1 mol / L) and deionized water several times u...

Embodiment 2

[0076] Utilize iron ferric oxide / reduced graphene oxide nanocomposite material to improve the method for dark fermentation hydrogen production, the preparation of ferric iron tetroxide / reduced graphene oxide nanocomposite material is as described in example 1,

[0077] Specific steps are as follows:

[0078] (1) Collect the anaerobic sludge of the citric acid wastewater treatment plant (located in Weifang, Shandong), the water content of the anaerobic sludge of the citric acid wastewater treatment plant is about 80%. The anaerobic sludge screening and cultivation measures are as follows: add 1.0g / L glucose and carry out anaerobic cultivation at 37°C for 20 days. The ratio of the inoculum with active hydrogen-producing bacteria to the total fermentation volume is 3:10; the middle temperature is 37°C.

[0079] (2) The anaerobic sludge obtained in step (1) is heat-treated with the cultivated sludge, and the enriched sludge is preheated at 90° C. for 30 minutes, The activity of ...

Embodiment 3

[0085] The preparation of ferric oxide / reduced graphene oxide nanocomposite is as described in example 1.

[0086] Utilize iron ferric oxide / reduced graphene oxide nanocomposite material to improve the method for dark fermentation hydrogen production, concrete steps are as follows:

[0087] The anaerobic sludge of the citric acid wastewater treatment plant (located in Weifang, Shandong) was collected, and the water content of the anaerobic sludge of the citric acid wastewater treatment plant was about 80%. The anaerobic sludge screening and cultivation measures are as follows: add 1.0g / L glucose and carry out anaerobic cultivation at 37°C for 20 days. The ratio of the inoculum with active hydrogen-producing bacteria to the total fermentation volume is 3:10; the middle temperature is 37°C.

[0088] (2) The anaerobic sludge obtained in step (1) is heat-treated with the cultivated sludge, and the enriched sludge is preheated at 90° C. for 30 minutes, The activity of methanogens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetic strength | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com