Fabricated roller thrust ring and manufacturing method thereof

A manufacturing method and thrust ring technology, which is applied in the field of metallurgical equipment parts, can solve problems affecting turning speed, processing efficiency, and sealing surface grinding, so as to improve processing efficiency and surface quality, save costs and time, and reduce The effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below in conjunction with specific embodiments

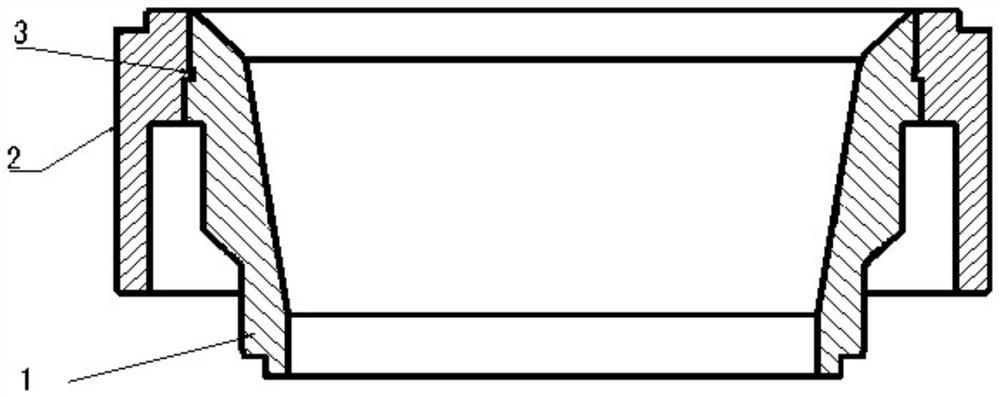

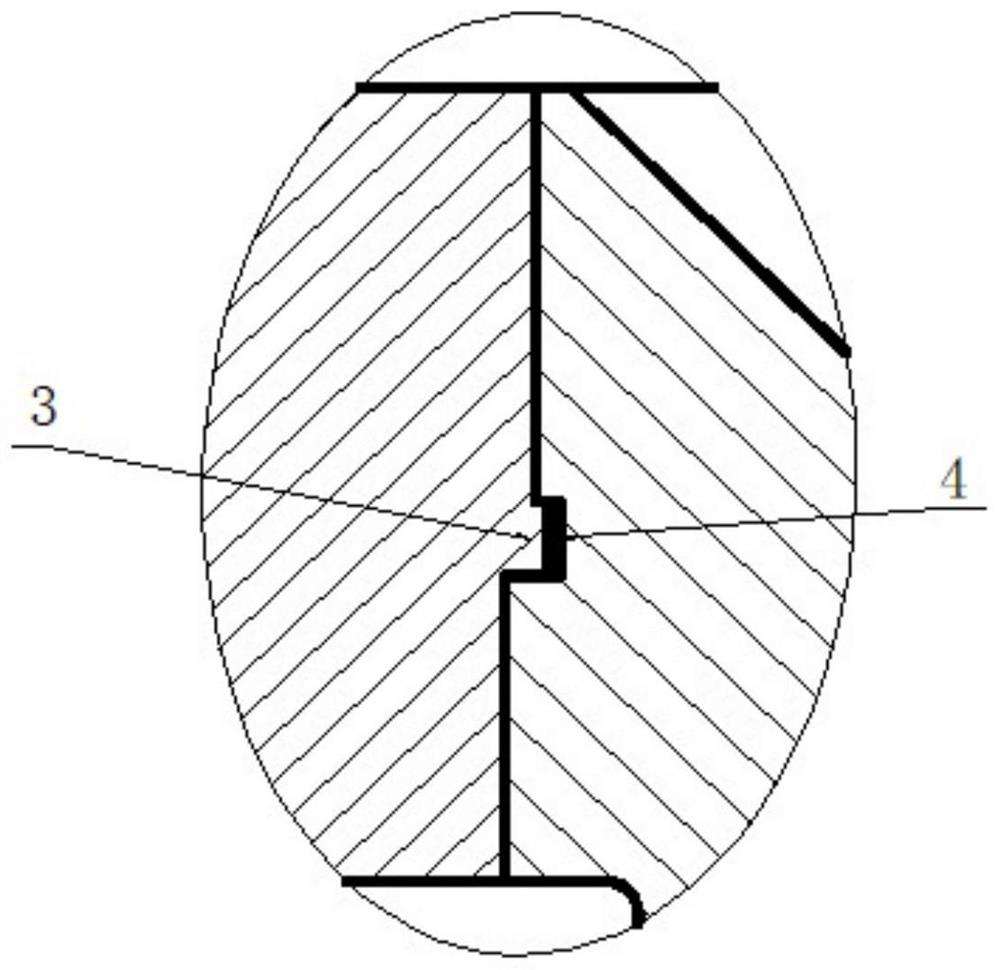

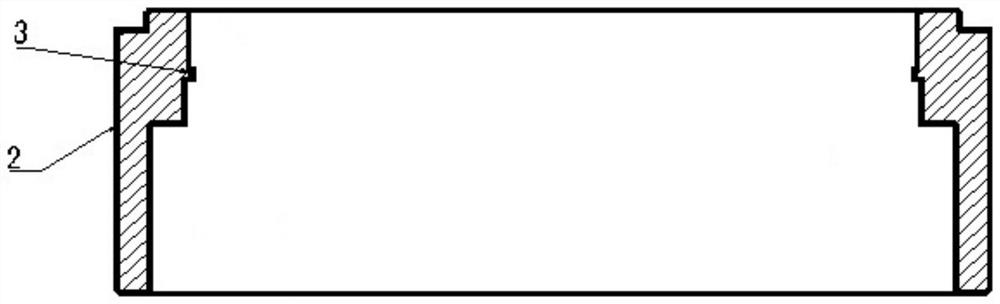

[0028] A large roll thrust ring such as Figure 1-4 As shown, it includes an overcoat 2 and an inner cover 1, the overcoat 2 is barrel-shaped, and its cross section is a door shape. The inner shoulder of the overcoat 2 is provided with a step platform one, and the inner diameter of the upper part of the step platform one is smaller than the inner diameter of the lower part, and The step of step platform 1 is provided with a boss 3, the inner sleeve 1 is a trapezoidal barrel-shaped structure, the outer wall is provided with multiple irregular steps, the outer shoulder of the inner sleeve 1 is provided with a step platform 2, and the upper part of the step platform 2 The outer diameter is smaller than the outer diameter of the lower part, and the step of the step platform 2 is provided with a slot 4. After the outer sleeve 2 and the inner sleeve 1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com