Preparation method of perindopril impurity K

A perindopril and impurity technology, which is applied in the field of preparation of perindopril impurity K, can solve the problems of less disclosure of the synthesis process, and achieve the effect of simple operation and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

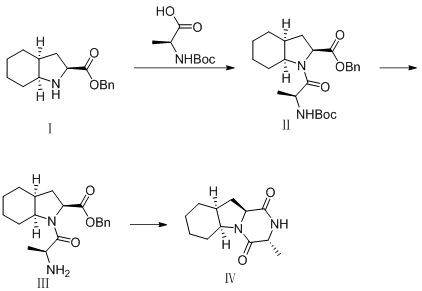

Image

Examples

Embodiment 1

[0022] (1) Dissolve compound I (5.2g, 20mmol), N-tert-butoxycarbonyl-L-alanine (4.15g, 22mmol) in DCM (100ml), then add HOBT (2.97g, 22mmol) and DCC (4.12g, 20mmol) was reacted at room temperature overnight. After the reaction was completed, the reaction solution was filtered, the filtrate was concentrated, and the residue was extracted by adding saturated sodium bicarbonate solution (150ml) and DCM (100ml×3). Dry over sodium sulfate and concentrate to obtain compound II.

[0023] (2) Compound II (8.6g, 20mmol) was dissolved in DCM (40ml), cooled to 0°C, and then TFA (10ml) was slowly added dropwise. After the addition was completed, the temperature was raised to room temperature, and the reaction was continued for 4h, and the reaction solution was concentrated. Saturated sodium bicarbonate (150ml) and DCM (100ml×3) were added to the residue for extraction, the organic phases were combined, dried over anhydrous sodium sulfate, and concentrated to obtain compound III.

[0024]...

Embodiment 2

[0026] (1) Dissolve compound Ⅰ (5.2g, 20mmol), N-tert-butoxycarbonyl-L-alanine (4.15g, 22mmol) in DCM (100ml), then HATU (11.4g, 30mmol), react at room temperature Overnight, after the reaction was completed, the reaction solution was filtered, the filtrate was concentrated, and the residue was extracted by adding saturated sodium bicarbonate solution (150ml) and DCM (100ml×3). The organic phases were combined, dried over anhydrous sodium sulfate, and concentrated to obtain compound II.

[0027] (2) Dissolve compound II (8.6g, 20mmol) in DCM (40ml), cool to 0°C, then slowly add 2M dioxane hydrochloride (30ml) dropwise, after the addition is complete, warm up to room temperature, and continue the reaction for 4h , the reaction solution was concentrated, saturated sodium bicarbonate (150ml) and DCM (100ml×3) were added to the residue for extraction, the organic phases were combined, dried over anhydrous sodium sulfate, and concentrated to obtain compound III.

[0028] (3) Dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com