Magnetic suspension sample rack vehicle guiding device for coating equipment and coating equipment

A technology of coating equipment and guiding devices, which is applied in the direction of support frame, sputtering coating, transportation and packaging, etc., can solve the problems of rolling smoothness decline, staggered precession, affecting the uniformity of coating, etc., to achieve simplified structure, mobile The effect of stabilizing and improving the coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

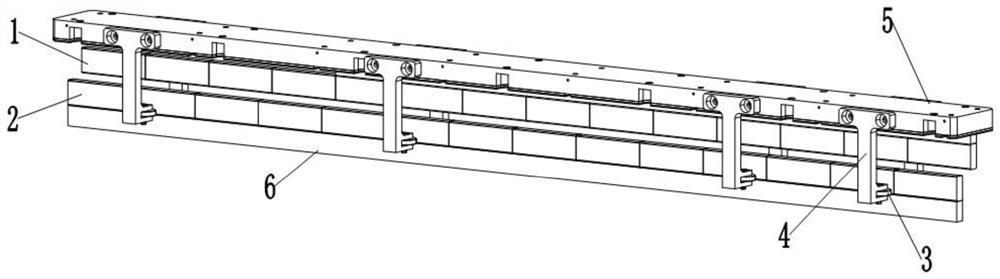

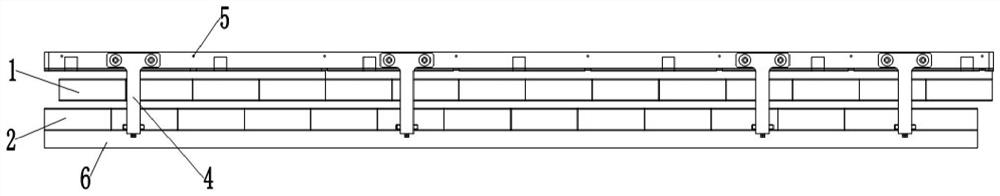

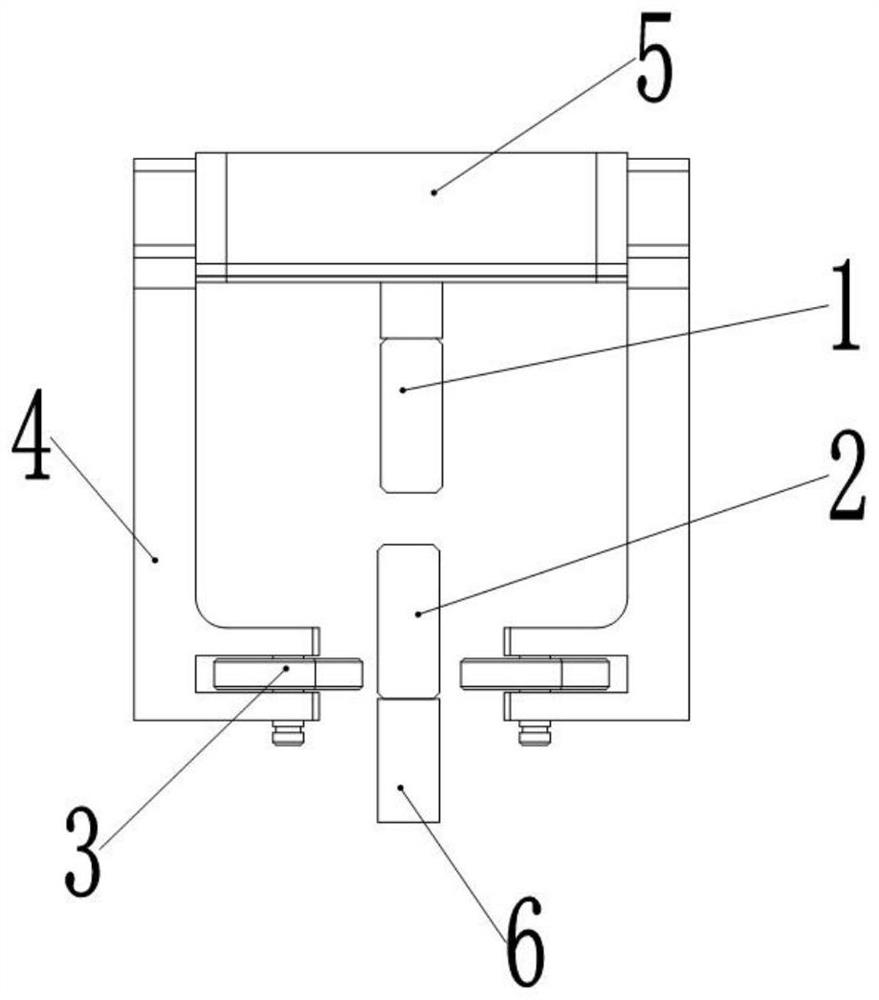

[0027] This embodiment provides a magnetic levitation sample rack guide device for coating equipment, such as Figure 1~4 As shown, it includes: magnetic guide rail 1 and magnetic guide slider 2, magnetic guide rail 1 and magnetic guide slider 2 form a magnetic levitation guide rail motion pair, magnetic guide rail 1 is used to be fixed on the top of the coating chamber, and magnetic guide slider 2 is used for Being fixedly arranged on the top of the sample rack cart 7, the magnetic guide slider 2 can move along the magnetic guide rail 1 under the action of magnetic force.

[0028] The magnetic levitation sample rack car guide device for coating equipment provided in this embodiment provides guidance to the sample rack car 7 through the magnetic levitation guide rail kinematic pair, and the non-contact guide method that does not rely on rollers avoids the frictional resistance brought by the contact type and simplifies the structure. . After a long time of coating operation, ...

Embodiment 2

[0035] This embodiment provides a kind of coating equipment, such as Figure 5 Shown, comprise coating cavity, sample rack car 7, bottom guide rail and the magnetic levitation sample rack car guiding device of the coating equipment in embodiment one, sample rack car 7 and bottom guide rail are all arranged in the coating chamber, sample rack car 7 can Moving along the bottom guide rail, the magnetic guide rail 1 is fixed on the top of the coating chamber, and the magnetic guide slider 2 is fixed on the top of the sample rack car 7 .

[0036] The coating equipment provided in this embodiment provides guidance to the sample rack vehicle 7 through the moving pair of the magnetic levitation guide rail, and the non-contact guiding method that does not rely on rollers avoids the frictional resistance caused by the contact type, and simplifies the structure. After a long time of coating operation, the sample rack car 7 will not run smoothly due to the adhesion of the internal frame s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com