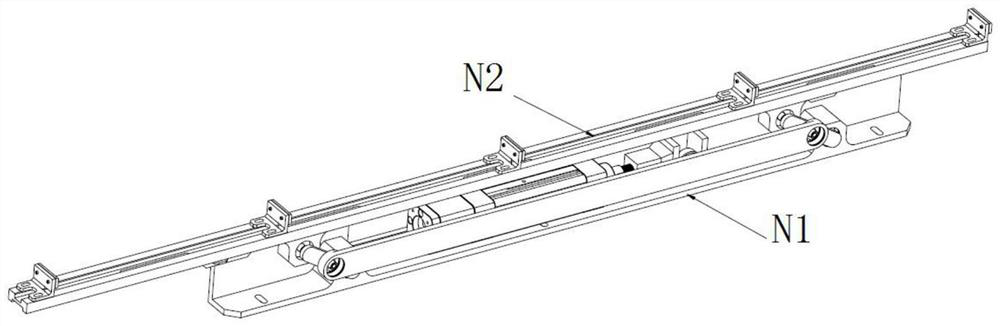

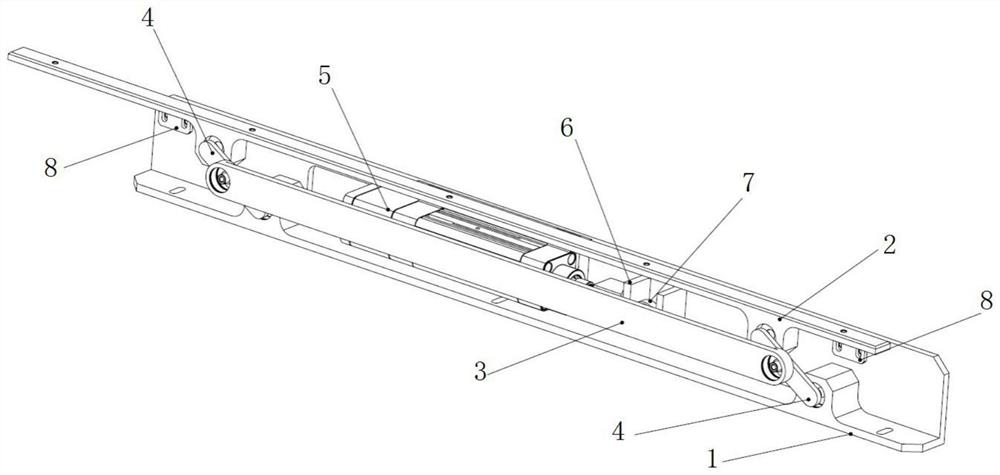

Flexible multi-station continuous clamping device and method

A clamping device and multi-station technology, used in packaging, packaging cigarettes, etc., can solve the problems of inability to adjust, random stop position of workpiece, lack of clamping force, etc., to reduce cycle time and improve work stability. , The effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

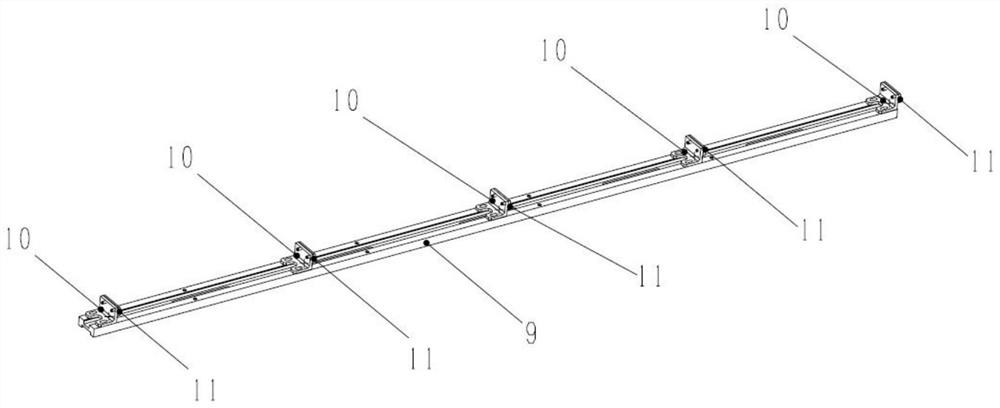

Embodiment 1

[0065] This example is mainly used in the step-by-step production line, where the workpiece cannot be clamped during transportation, but it needs to be positioned and clamped when it is transported to the action station.

[0066] See Figure 5 (clamping state), the workpiece is transported by the conveyor belt 12 into the clamping station, the workpiece is pushed forward by the lug 13 on the conveyor belt, and is transported to the clamping station, and the positioning of the workpiece is completed by the clamping device and the lug and clamping (see Figure 5 ). In the example, the distance between the stations is M, that is, the distance between the clamping movable plates in the clamping device is M, and the distance between the lugs of the conveyor belt is also M. The two phases cooperate to complete the simultaneous clamping of multiple stations; for the distance L of the clamped workpiece The adjustment can be realized in two ways. One is to control the vertical displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com