Fuel supply structure of vane type internal combustion engine

A fuel supply, internal combustion engine technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of rising costs and unexplained details, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

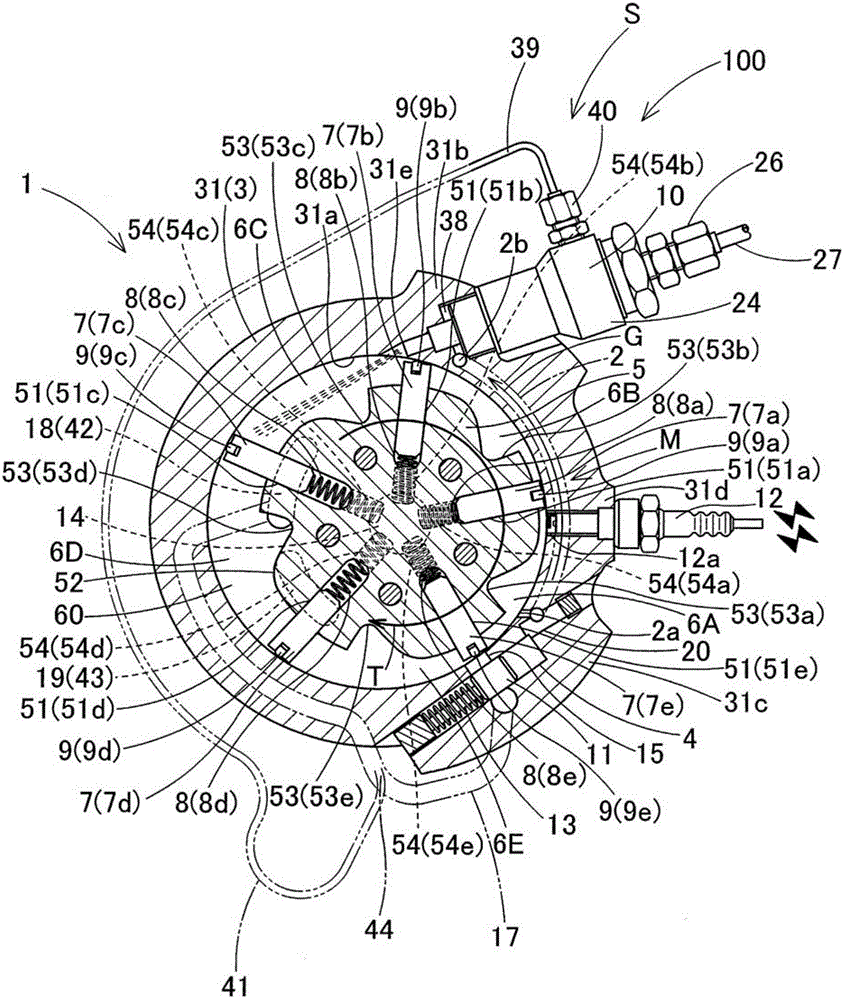

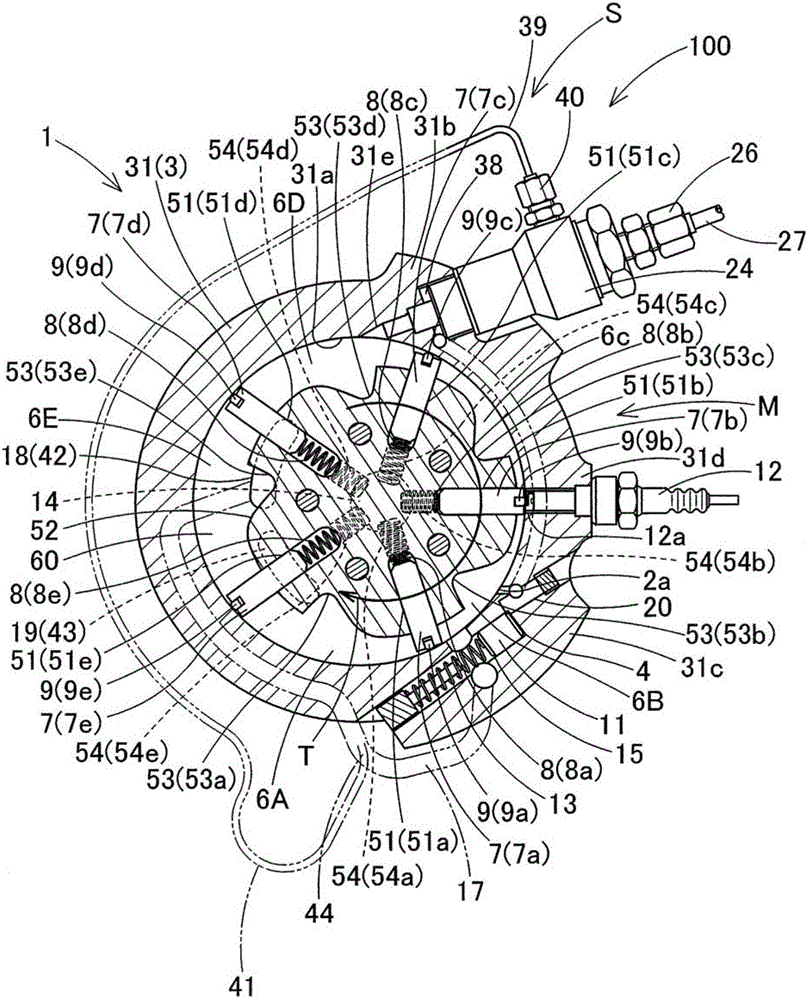

[0032] One embodiment of the fuel supply structure of the vane type internal combustion engine according to the present invention will be described with reference to the drawings. The fuel supply structure (hereinafter referred to as "fuel supply structure") 100 of the vane type internal combustion engine of the present invention solves the problem that the fuel nozzle stops due to the failure of the electrical system.

[0033] The vane type internal combustion engine (hereinafter referred to as "engine") 1 having the fuel supply structure 100 of the embodiment is configured to sequentially repeat explosion, expansion, exhaust, air intake, air compression, supercharging, and scavenging in one cycle. , Compressed air intake, mixed gas compression stroke.

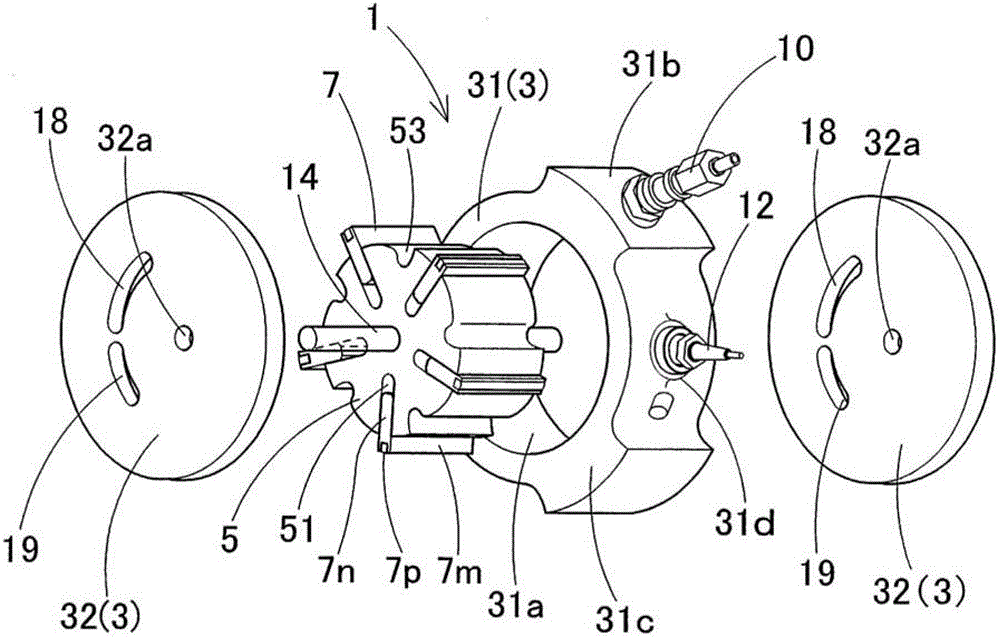

[0034] engine 1 as image 3 As shown, there is: a housing 3, which has a substantially cylindrical housing body portion 31 and a pair of side housing portions 32, 32, which are disposed on the sides of the housing body porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com