Roll changing and material receiving mechanism of film blowing machine

A material receiving mechanism and film blowing machine technology, applied in the direction of winding strips, thin material processing, flat products, etc., can solve the problems of low production efficiency and achieve the effect of convenient roll changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

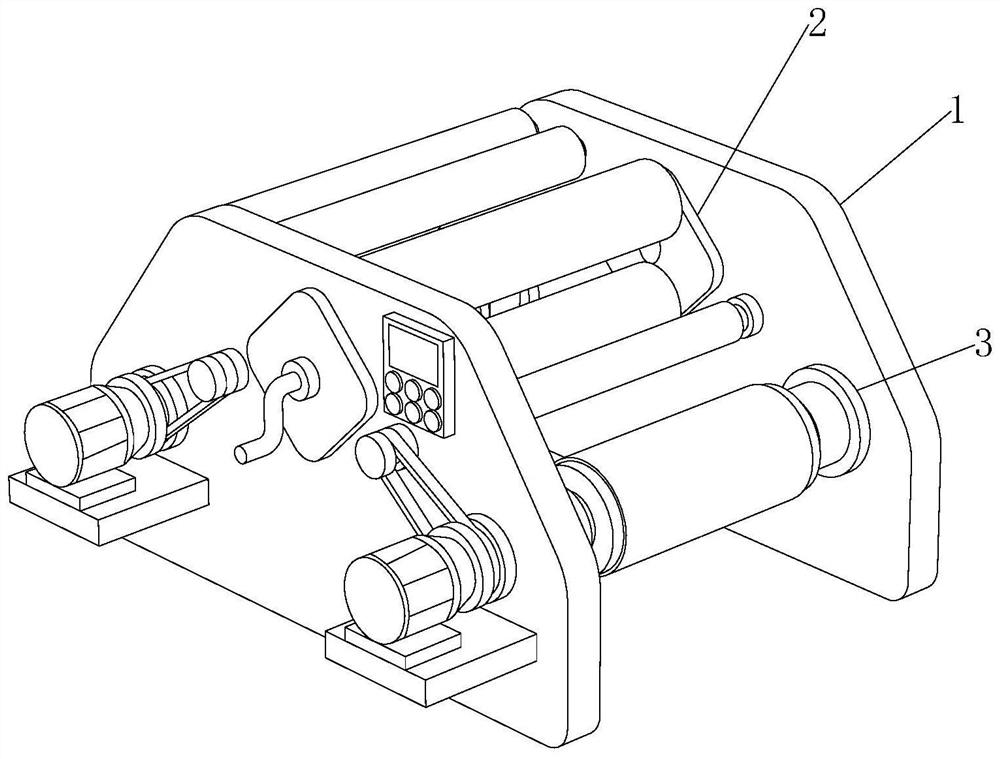

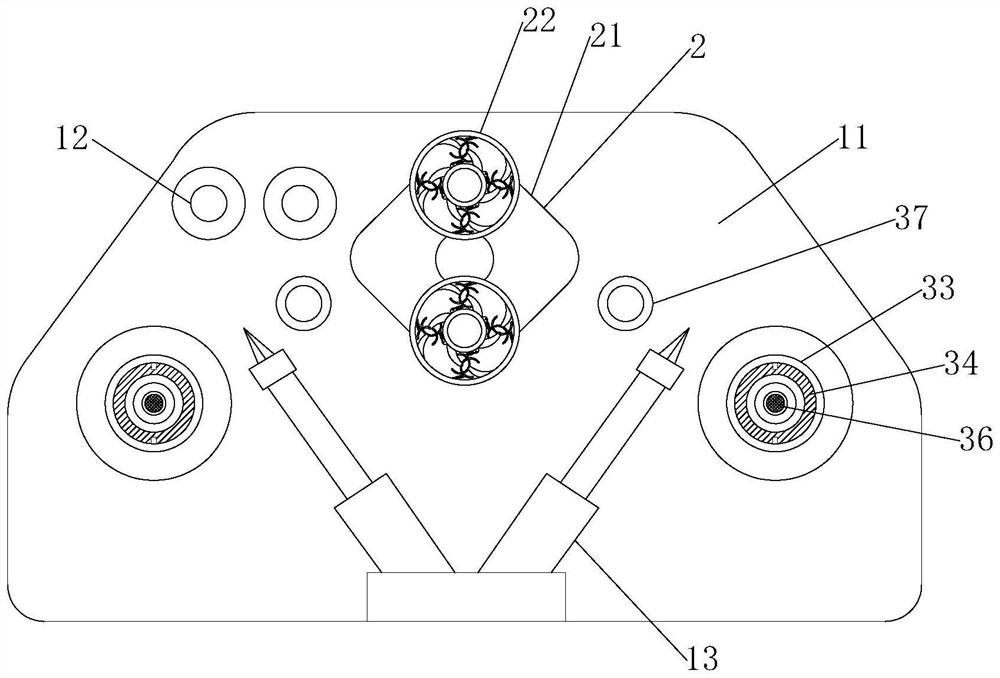

[0034] like Figure 1-9 As shown, the present invention provides a roll changing and receiving mechanism for a film blowing machine, including a roll changing and receiving mechanism main body 1, and the roll changing and receiving mechanism main body 1 includes a mechanism frame 11, and a film feeding roller is movably installed at the front end of the mechanism frame 11 12. The lower end of the mechanism frame 11 is provided with a cutting device 13, one side of the film feeding roller 12 is provided with a roll-changing guide mechanism 2, and the lower end of the roll-changing guide mechanism 2 is provided with a receiving device 3, and the roll-changing guide mechanism 2 includes The reversing frame 21 and the film guide roller 22, the surface of the reversing frame 21 is movably connected with the inner wall of the mechanism frame 11, and the receiving device 3 includes a motor 31, a driving pulley 32, a receiving roller installation sleeve 33, and a receiving roller 34 ,...

Embodiment 2

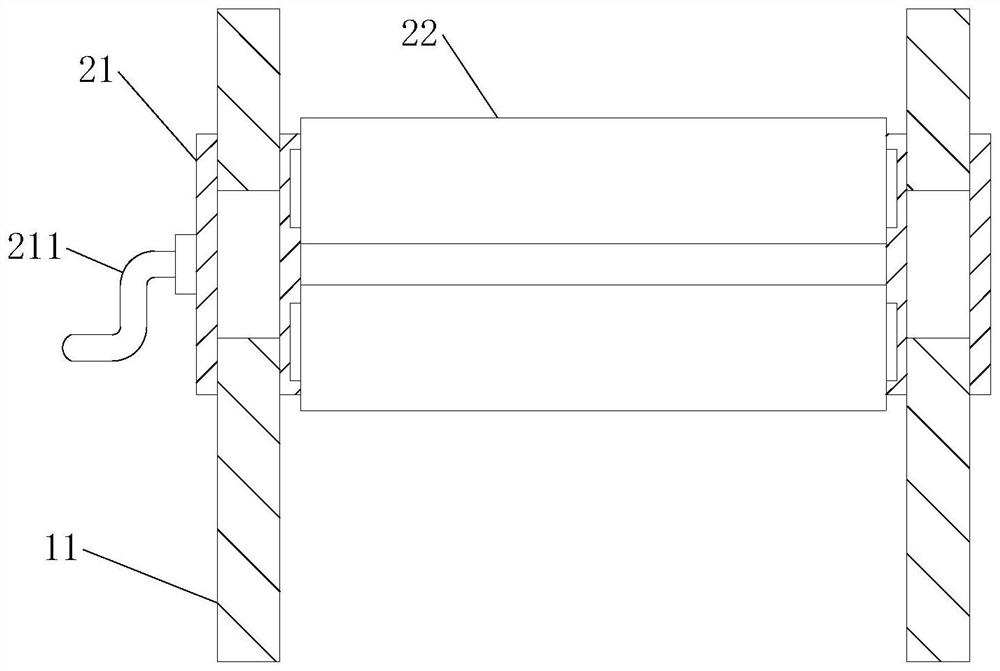

[0037] like Figure 1-9 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the outer surface of the fixed shaft 221 is movably connected with the inner surface of the movable sleeve 222, and a rubber plate 2221 is arranged between the movable sleeve 222 and the membrane guide sleeve 223 , both sides of the rubber plate 2221 are movably equipped with a rotating rod 2222, and one end of the rotating rod 2222 is fixedly connected with the surface of the guide film sleeve 223 and the movable sleeve 222 respectively, and the two ends of the rubber plate 2221 are fixedly installed with a spring connecting rod 2223, and the spring is connected One end of the rod 2223 is hinged to the surfaces of the guide membrane sleeve 223 and the movable sleeve 222 respectively.

[0038] In this embodiment, the fixed shaft 221 and the movable sleeve 222 cooperate with each other to make the guide film sleeve 223 rotate to reduce the friction between the pl...

Embodiment 3

[0040] like Figure 1-9As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the output end of the motor 31 is fixedly connected to one end of the driving pulley 32, a driven pulley 321 is arranged above the driving pulley 32, and the driving pulley 32 The other end of wheel 32 and driven pulley 321 is movably connected with the inwall of mechanism frame 11, belt 322 is movably installed between driven pulley 321 and driving pulley 32, and the outer surface of receiving roller mounting sleeve 33 is connected with driving belt. The side surface of the wheel 32 is fixedly connected, the inner surface of the receiving roller installation sleeve 33 is provided with a socket adapted to the receiving roller 34, the inner wall of the receiving roller installation sleeve 33 is provided with a block, and the outer surface of the receiving roller 34 A card slot is provided, and the outer surface of the receiving roller 34 is movably connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com