Hazardous chemical loading and unloading device for modern logistics

A technology for chemical dangerous goods and loading and unloading devices, which is applied in the direction of transportation and packaging, trolley accessories, multi-axis trolleys, etc. It can solve the problems of lack of fastening facilities and inability to carry out docking and transfer, so as to avoid dumping, avoid shaking, and improve transfer efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

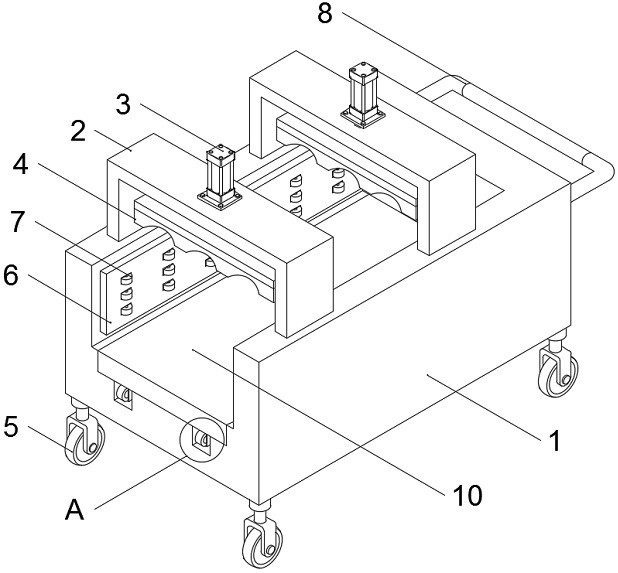

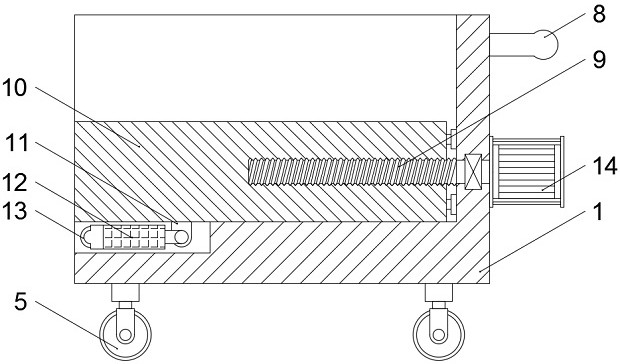

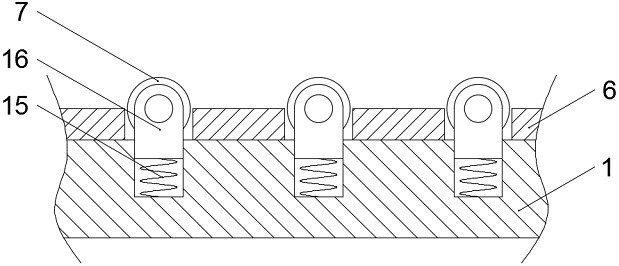

[0026] as attached figure 1 to attach Figure 4 Shown:

[0027] The present invention provides a modern logistics equipment for loading and unloading hazardous chemicals. The installation and use of the support shaft 12 enables the stable right-angle swing. One side of a pair of connecting pins 11 is respectively movably connected to the support shaft 12, and one end of the two support shafts 12 is respectively connected to the second pulley 13. The inner wall of the loading and unloading vehicle 1 One side is movably connected with a threaded rod 9, one end of the threaded rod 9 is threadedly connected with one side of the slide plate 10, a motor 14 is installed on one side of the outer wall of the loading and unloading vehicle 1, and the output end of the motor 14 runs through the loading and unloading vehicle 1, and is connected with the threaded rod 9 in transmission A pair of top frames 2 are welded on the side of the top of the loading and unloading truck 1, and chutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com