An online monitoring device for metal 3D laser printing

A technology of laser printing and monitoring equipment, applied in the direction of additive processing, etc., can solve the problems of lack of data analysis ability, no feedback mechanism, low survival rate, etc., to improve image acquisition quality, increase adjustable range, and high image consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

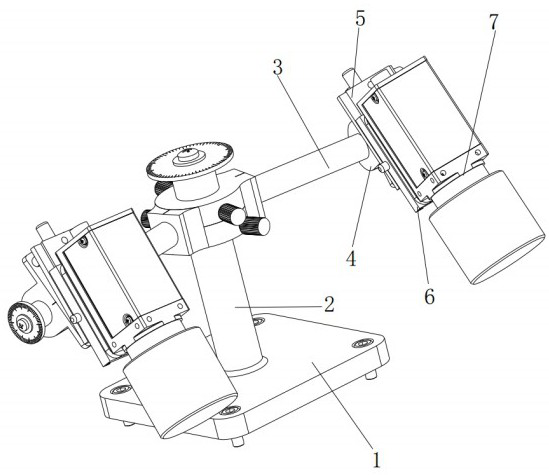

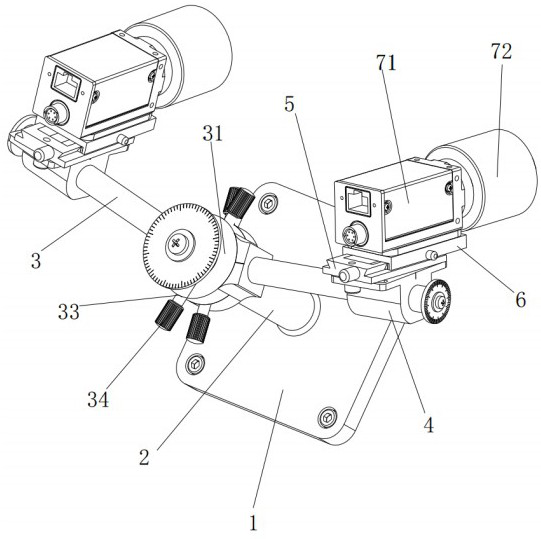

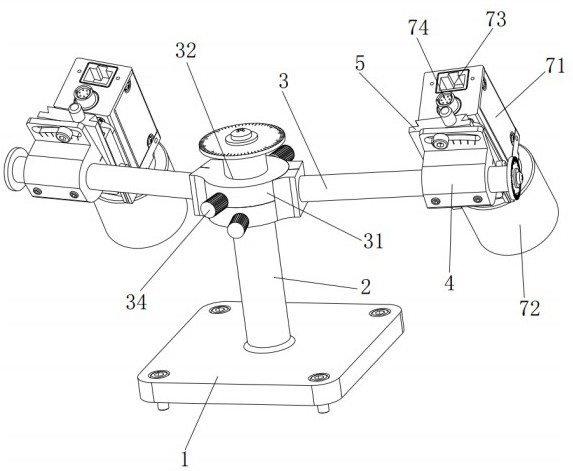

[0029] see Figure 1-5 As shown, the online monitoring equipment for metal 3D laser printing provided by the embodiment of the present invention includes a support 1, a column 2 is fixed on the support 1, two cantilever rods 3 are slidably arranged on the column 2, and the two Each cantilever rod 3 can be rotated around the upright column 2 independently, an adjustment seat 4 is slid on the cantilever rod 3, and the adjustment seat 4 can rotate around the cantilever rod 3, and a track plate 5 is rotated on the adjustment seat 4, and on the track plate A mounting seat 6 is slidably provided on the 5 , and a camera assembly 7 is fixed on the mounting seat 6 .

[0030] Through the above structure, in practical application, using the online monitoring equipment for metal 3D laser printing of the present invention, the camera assembly 7 is fixedly installed on the mounting seat 6, and the mounting seat 6 can slide on the track plate 5, so the camera assembly can be driven 7 slides...

Embodiment 2

[0039] see Figure 1-7 As shown in the figure, the usage scenario of the online monitoring equipment for metal 3D laser printing provided by the embodiment of the present invention includes a powder bed substrate 9 and a top plate 8 arranged above the powder bed substrate 9, which are used for the fixed setting of the online monitoring equipment for metal 3D laser printing. On one side of the top plate 8, the online monitoring equipment for metal 3D laser printing includes a support 1, a column 2 is fixed on the support 1, and two cantilever rods 3 are slidably arranged on the column 2, and the two cantilever rods 3 can be rotated around the column 2 independently, and the adjustment seat 4 can be slid on the cantilever rod 3, and the adjustment seat 4 can be rotated around the cantilever rod 3. A mounting seat 6 is provided, and a camera assembly 7 is fixed on the mounting seat 6 .

[0040] Through the above structure, in practical application, using the online monitoring eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com