Method for making coffee through hydrothermal reaction

A hydrothermal reaction and coffee technology, applied in the method of grinding coffee, coffee extraction, green coffee processing, etc., can solve the problem of reducing flavor and achieve the effect of reducing requirements and enriching types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for making coffee through hydrothermal reaction.

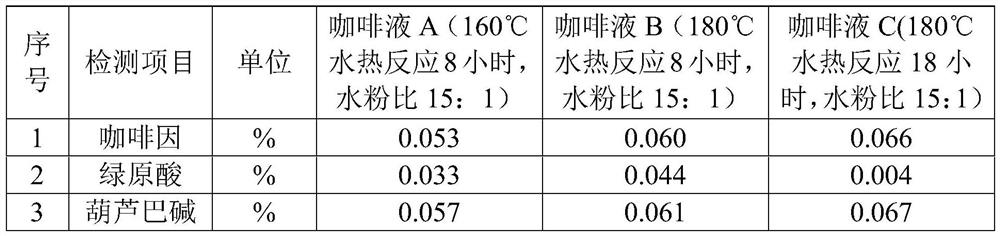

[0045] (1) Grind green coffee beans into powder, control the particle size between 0.45mm-1.45mm, and make green coffee powder (such as figure 1 shown).

[0046] (2) Take 2 grams of raw coffee powder, add it to a 100-ml reactor liner, and add 15 ml of distilled water.

[0047] (3) Cover the inner tank tightly and put it into the stainless steel outer tank, put it into the oven after tightening the stainless steel outer tank, adjust the temperature to 160 degrees Celsius, and control the reaction time for 8 hours.

[0048] (4) The oven cools down naturally, takes out the reaction kettle, opens the outer container and the inner container, pours out the supernatant, and obtains coffee (such as figure 2 shown).

[0049] The comprehensive evaluation of the coffee obtained in Example 1 by 5 tasters is:

[0050] Smell: moist, caramel;

[0051] Taste: sour plum, caramel.

Embodiment 2

[0053] This embodiment provides a method for making coffee through hydrothermal reaction.

[0054] (1) Grind the green coffee beans into powder, and control the particle size between 0.45mm and 1.25mm to make green coffee powder.

[0055] (2) Take 2 grams of raw coffee powder, add it to a 100-ml reactor liner, and add 15 ml of distilled water.

[0056] (3) Cover the inner tank tightly and put it into the stainless steel outer tank, put it into the oven after tightening the stainless steel outer tank, adjust the temperature to 180 degrees Celsius, and control the reaction time for 8 hours.

[0057] (4) The oven is cooled naturally, the reaction kettle is taken out, the outer container and the inner container are opened, and the supernatant is poured out to obtain coffee.

[0058] The comprehensive evaluation of the coffee that 5 tasters obtain to embodiment 2 is:

[0059] Smell: Caramel, roasted nuts;

[0060] Tasting taste: It has the taste of emblica (acid with astringency) ...

Embodiment 3

[0062] This embodiment provides a method for making coffee through hydrothermal reaction.

[0063] (1) Grind the green coffee beans into powder, and control the particle size between 0.45mm and 1.25mm to make green coffee powder.

[0064] (2) Take 2 grams of raw coffee powder, add it to a 100-ml reactor liner, and add 15 ml of distilled water.

[0065] (3) Cover the inner tank tightly and put it into the stainless steel outer tank, put it into the oven after tightening the stainless steel outer tank, adjust the temperature to 180 degrees Celsius, and control the reaction time for 18 hours.

[0066] (4) The oven is cooled naturally, the reaction kettle is taken out, the outer container and the inner container are opened, and the supernatant is poured out to obtain coffee.

[0067] The comprehensive evaluation of the coffee that 5 tasters obtain to embodiment 3 is:

[0068] Smell: moist, caramel;

[0069] Tasting Palate: Aromas of caramel, chocolate, roasted grains.

[0070]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com